This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

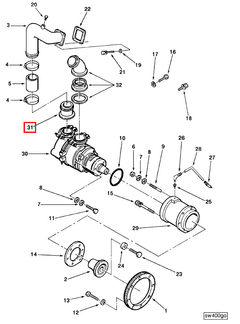

The Sea Water Connection 3050954 by Cummins is a specialized component designed for use in commercial trucks, particularly those equipped with engines that utilize seawater for cooling. This part facilitates the connection between the engine’s cooling system and the seawater intake, ensuring efficient heat dissipation and maintaining optimal engine temperature during operation 1.

Basic Concepts of Sea Water Connection

A Sea Water Connection is a component in the cooling systems of marine and industrial engines. It allows seawater to be drawn into the engine’s cooling system, where it absorbs heat from the engine components before being expelled back into the sea. This process plays a role in maintaining the engine’s operating temperature within safe limits, preventing overheating and potential damage 2.

Purpose of the 3050954 Sea Water Connection

The 3050954 Sea Water Connection is designed to facilitate the efficient transfer of seawater into the engine’s cooling system. By providing a secure and reliable connection point, it ensures that the cooling process is uninterrupted, which is particularly important in engines that operate under high loads or in environments where ambient cooling is insufficient 3.

Key Features

The 3050954 Sea Water Connection features a robust design that includes corrosion-resistant materials to withstand the harsh marine environment. Its construction incorporates precise threading and sealing mechanisms to prevent leaks and ensure a tight connection. Additionally, the connection is designed for easy installation and maintenance, featuring accessible ports for inspection and servicing 4.

Benefits

The use of the 3050954 Sea Water Connection offers several benefits, including enhanced engine cooling efficiency due to its design that allows for a consistent flow of seawater. Its durable construction contributes to the longevity of the cooling system, reducing the need for frequent replacements. Furthermore, the reliable connection it provides helps in maintaining the engine’s performance and reliability over time 5.

Installation Process

Installing the 3050954 Sea Water Connection involves several steps. First, ensure the engine is cool and the cooling system is drained. Then, remove the old connection if replacing an existing one. Clean the installation area to remove any debris or old sealant. Apply a compatible sealant to the threads of the new connection, then screw it into place by hand until snug, followed by a final tightening with the appropriate tool. Finally, refill the cooling system with seawater and check for leaks 6.

Common Issues and Troubleshooting

Common issues with the 3050954 Sea Water Connection may include leaks, corrosion, or blockages. To address leaks, ensure the connection is properly tightened and that the sealant is applied correctly. Corrosion can be mitigated by using the connection in conjunction with corrosion inhibitors in the cooling system. Blockages may require disassembling the connection to clear any debris 7.

Maintenance Tips

Regular maintenance of the 3050954 Sea Water Connection involves inspecting it for signs of wear, corrosion, or leaks during routine engine maintenance checks. Cleaning the connection and its surrounding areas can prevent debris buildup, which may lead to blockages. Additionally, applying a fresh layer of sealant during maintenance can help ensure a leak-free connection 8.

Compatibility and Applications

The 3050954 Sea Water Connection is compatible with a range of Cummins engines used in commercial trucking applications, particularly those designed for marine or industrial use where seawater cooling is employed 9.

Safety Considerations

When installing, maintaining, or troubleshooting the 3050954 Sea Water Connection, it is important to follow safety guidelines. Ensure the engine is cool before beginning work to avoid burns. Use the appropriate tools and personal protective equipment to prevent injuries. Additionally, be mindful of the environmental impact of any coolant or sealant used, opting for environmentally friendly products where possible 10.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the industry for producing reliable and efficient power systems 11.

Sea Water Connection Part 3050954 in Cummins Engines

The Sea Water Connection part 3050954 is a critical component in the marine engine systems, facilitating the intake of seawater for cooling purposes. This part is designed to integrate seamlessly with various Cummins marine engines, ensuring efficient operation and reliability in demanding marine environments 12.

K19 Engine Series

In the K19 engine series, the Sea Water Connection part 3050954 plays a pivotal role in the engine’s cooling system. It is engineered to withstand the harsh conditions of marine operations, providing a durable and reliable connection for seawater intake. This part is essential for maintaining optimal engine performance by ensuring that the cooling system functions effectively, preventing overheating and extending the engine’s lifespan 13.

Role of Part 3050954 Sea Water Connection in Engine Systems

The Part 3050954 Sea Water Connection is integral to the efficient operation of various marine engine systems. This component facilitates the necessary flow of sea water, which is vital for the cooling and lubrication of engine parts 14.

Integration with Sea Water Pump Kit

When integrated with the Kit 2-Sea Water Pump, the Sea Water Connection ensures a consistent and reliable supply of sea water to the pump. This setup is essential for maintaining optimal engine temperature by circulating cool sea water through the engine’s cooling passages 15.

Function in Raw Water Systems

In systems utilizing a Raw Water Pump, the Sea Water Connection acts as the initial point of entry for raw water into the engine’s cooling system. It connects directly to the raw water intake, allowing unfiltered sea water to be drawn in and circulated through the engine block and exhaust manifolds. This continuous flow helps dissipate heat generated during engine operation 16.

Enhancing Pump Performance

The Sea Water Connection also plays a supportive role in the overall performance of the Pump. By providing a secure and leak-free connection, it ensures that the pump can operate efficiently without interruptions. This reliability is key to preventing overheating and potential engine damage 17.

Raw Water Pump Compatibility

For engines equipped with a Raw Water Pump, the Sea Water Connection is designed to interface seamlessly with the pump’s intake port. This compatibility ensures that the raw water pump can effectively draw in sea water, which is then pressurized and distributed throughout the engine’s cooling circuits 18.

Conclusion

In summary, the Part 3050954 Sea Water Connection is a fundamental component in marine engine systems, ensuring the smooth and efficient circulation of sea water for cooling purposes. Its proper installation and maintenance are essential for the longevity and performance of the engine 19.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014

↩ -

QSK23 CM2350 K127, Bulletin Number 5504159, Operation and Maintenance Manual

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014

↩ -

QSK23 CM2350 K127, Bulletin Number 5504159, Operation and Maintenance Manual

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014

↩ -

QSK23 CM2350 K127, Bulletin Number 5504159, Operation and Maintenance Manual

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014

↩ -

QSK23 CM2350 K127, Bulletin Number 5504159, Operation and Maintenance Manual

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.