This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

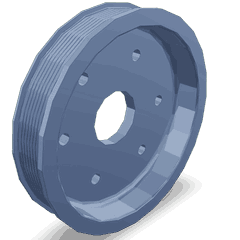

The Cummins 3046360 Crankshaft Pulley is a critical component in commercial truck engines, facilitating the transfer of rotational force from the crankshaft to various engine accessories. Understanding its function and importance is essential for maintaining the efficiency and performance of commercial trucks.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a toothed wheel attached to the front of an engine’s crankshaft. Its primary function is to drive engine accessories such as the alternator, water pump, and air conditioning compressor via a belt or chain. The pulley helps maintain the smooth operation of these accessories by reducing torsional vibrations that occur during engine operation 1.

Purpose of the 3046360 Crankshaft Pulley

This Cummins part is integral to the operation of a truck engine. It plays a role in driving various engine accessories by transferring rotational energy from the crankshaft. This ensures that components such as the alternator, which generates electrical power, and the water pump, which circulates coolant, operate efficiently. The pulley also helps in dampening vibrations, contributing to a smoother engine operation 2.

Key Features

The 3046360 Crankshaft Pulley is constructed with high-quality materials to ensure durability and performance. It features a robust design that includes a dampening element to reduce vibrations. The pulley is engineered to withstand the high stresses and temperatures encountered in commercial truck engines. Its precise manufacturing ensures a perfect fit and efficient operation 3.

Benefits

This part offers several advantages. It contributes to improved engine performance by ensuring that accessories are driven efficiently. The pulley’s design helps in reducing wear and tear on the engine components, leading to increased durability. Additionally, it plays a role in enhancing the overall efficiency of the engine by minimizing energy loss due to vibrations 4.

Installation Process

Installing the 3046360 Crankshaft Pulley requires careful attention to detail. The process involves aligning the pulley with the crankshaft and securing it in place using the appropriate fasteners. It is important to ensure that the pulley is properly aligned to prevent issues such as belt slippage or increased wear. Tools such as a torque wrench may be required to tighten the fasteners to the specified torque settings.

Maintenance Tips

To ensure the optimal performance and longevity of the 3046360 Crankshaft Pulley, regular maintenance is recommended. This includes inspecting the pulley for signs of wear or damage, ensuring that the belt or chain is properly tensioned, and cleaning the pulley to remove any buildup of dirt or debris. Following the manufacturer’s maintenance schedule can help in identifying and addressing potential issues before they become serious problems.

Troubleshooting Common Issues

Common issues associated with the 3046360 Crankshaft Pulley may include belt slippage, unusual noises, or vibrations. These issues can often be traced back to improper installation, wear and tear, or misalignment. Troubleshooting steps may involve inspecting the pulley and belt for damage, ensuring proper alignment, and replacing worn components as necessary.

Compatibility and Applications

The 3046360 Crankshaft Pulley is designed for specific types of engines and vehicles. It is important to verify compatibility with the engine model and make to ensure proper fit and function. This information can typically be found in the product documentation or by consulting with a knowledgeable professional.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. With a history of developing reliable and efficient engine components, Cummins has built a reputation for excellence. The company’s focus on research and development ensures that its products, including the 3046360 Crankshaft Pulley, meet the high standards required for commercial truck applications.

Crankshaft Pulley Part 3046360 Compatibility with Cummins Engines

The Crankshaft Pulley part number 3046360, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is crucial for the operation of the engine’s accessory drive system, ensuring that components such as the alternator, water pump, and air conditioning compressor function correctly.

L10 CELECT

The L10 CELECT engine is one of the models that can utilize the Crankshaft Pulley part 3046360. This engine is known for its efficiency and reliability, often used in various heavy-duty applications. The compatibility of this pulley with the L10 CELECT engine ensures that the engine’s ancillary systems receive the necessary power and rotation.

L10 GAS

Similarly, the L10 GAS engine is another model that can integrate the Crankshaft Pulley part 3046360. This engine variant is designed to run on natural gas, providing an environmentally friendly alternative to diesel. The use of this specific pulley part ensures that the engine’s performance is maintained, and the ancillary systems operate smoothly.

L10 MECHANICAL

The L10 MECHANICAL engine also benefits from the Crankshaft Pulley part 3046360. This engine is typically used in applications where mechanical reliability and durability are paramount. The pulley’s design allows for efficient power transfer to the engine’s accessories, ensuring that the engine operates at optimal performance levels.

Group Compatibility

The Crankshaft Pulley part 3046360 is engineered to fit seamlessly within the L10 series engines, including the CELECT, GAS, and MECHANICAL variants. This compatibility is achieved through precise engineering and manufacturing standards, ensuring that the pulley meets the specific requirements of each engine model. The use of high-quality materials and rigorous testing processes guarantees that the pulley will perform reliably over the engine’s operational life.

Role of Part 3046360 Crankshaft Pulley in Engine Systems

The Part 3046360 Crankshaft Pulley is an integral component in the efficient operation of engine systems, particularly in relation to the damper and vibration management.

When the crankshaft rotates, the crankshaft pulley, which is directly attached to the crankshaft, also rotates. This rotation is transferred to the damper, a device designed to absorb and dampen the torsional vibrations produced by the engine’s operation. The damper consists of a driving plate, a driven plate, and a layer of viscoelastic material in between. As the crankshaft pulley rotates, it drives the damper’s driving plate. The viscoelastic material then absorbs the torsional vibrations, reducing their impact on the engine’s components.

The crankshaft pulley also plays a significant role in managing engine vibrations. Engine vibrations are inevitable due to the reciprocating motion of the pistons and the rotating motion of the crankshaft. These vibrations can lead to wear and tear on the engine components if not properly managed. The crankshaft pulley, by transferring the rotational motion of the crankshaft to the damper, helps in reducing these vibrations.

Furthermore, the crankshaft pulley is often toothed or grooved to allow for the attachment of various engine accessories such as the alternator, power steering pump, and air conditioning compressor. These accessories are driven by belts that wrap around the pulley. As the crankshaft rotates, so does the pulley, driving these accessories and ensuring their proper operation.

Conclusion

In summary, the Part 3046360 Crankshaft Pulley is a key component in the engine system, playing a significant role in damper operation and vibration management, as well as driving essential engine accessories. Its proper installation, maintenance, and compatibility with specific engine models are crucial for ensuring the efficient and reliable operation of commercial truck engines.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Lakshminarayanan, P. A., and Nagaraj S. Nayak. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.