This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3046108 Subbase is a critical component in commercial trucks, designed to enhance the efficiency and reliability of the vehicle’s mechanical system. Understanding its function and importance is essential for fleet operators and mechanics, as it significantly impacts the truck’s performance and longevity.

Basic Concepts of a Subbase

In truck mechanics, a subbase is a foundational component that supports and integrates with various mechanical parts. It provides a stable platform for the attachment of other components, ensuring they are securely positioned and can function effectively. The subbase is vital for the structural integrity and operational efficiency of the truck’s mechanical systems.

Purpose of the 3046108 Subbase

The Cummins 3046108 Subbase is designed to serve a specific role within the engine or transmission system of a truck. It acts as a mounting platform for other components, ensuring they are correctly aligned and supported. This subbase contributes to the smooth operation of the engine or transmission by providing a stable and durable base.

Key Features

The Cummins 3046108 Subbase is characterized by several key features. It is constructed from high-quality materials that offer durability and resistance to wear and tear. The design of the subbase includes precise engineering to ensure compatibility with other components and to facilitate easy installation. Unique characteristics may include specific mounting points or a design that enhances the distribution of mechanical stresses.

Benefits

The advantages of using the Cummins 3046108 Subbase include improved durability, which contributes to the longevity of the truck’s mechanical systems. It also enhances performance by providing a stable platform for critical components. Additionally, the use of this subbase may lead to potential cost savings for fleet operators due to its reliability and the reduction in the need for frequent replacements or repairs 1.

Installation Process

Installing the Cummins 3046108 Subbase requires careful attention to detail. The process involves securing the subbase in the correct position, ensuring all mounting points are aligned, and verifying that it is firmly attached to prevent any movement during operation. It is important to follow manufacturer guidelines to ensure proper installation and to maintain the integrity of the truck’s mechanical system 2.

Common Issues and Troubleshooting

Frequent problems associated with the Cummins 3046108 Subbase may include misalignment during installation, which can lead to operational issues. Troubleshooting methods involve checking the installation process, ensuring all components are correctly positioned, and making any necessary adjustments. Solutions may include realigning the subbase or replacing damaged parts to restore proper function.

Maintenance Tips

Routine maintenance of the Cummins 3046108 Subbase is important to ensure its longevity and optimal performance. This includes regular inspections for signs of wear or damage, cleaning the subbase to remove any debris that may affect its function, and tightening any loose mounting points. Adhering to a maintenance schedule can help prevent issues and extend the life of the subbase 3.

Manufacturer Information - Cummins

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry. With a history of producing high-quality components, Cummins has built a reputation for reliability and innovation. Their commitment to quality is evident in the design and construction of components like the 3046108 Subbase, which are engineered to meet the demanding requirements of commercial truck operations.

Understanding the Role of Part 3046108 Subbase in Engine Systems

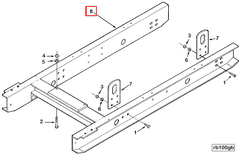

In the intricate architecture of engine systems, the 3046108 Subbase serves as a fundamental component that integrates seamlessly with various other components to ensure optimal engine performance. This subbase is engineered to provide a stable and secure foundation for the Base Rail, which is essential for the structural integrity of the engine.

The Base Rail, a critical element in the engine’s framework, relies on the Subbase for precise alignment and support. The Subbase ensures that the Base Rail is positioned accurately, which is vital for the proper functioning of the engine’s moving parts. This alignment is particularly important for components such as the pistons, crankshaft, and connecting rods, which must operate within tight tolerances to maintain efficiency and reliability.

Furthermore, the Subbase plays a significant role in managing the distribution of forces within the engine. By providing a robust platform for the Base Rail, it helps in evenly dispersing the loads generated during engine operation. This not only enhances the durability of the engine but also contributes to smoother operation by reducing vibrations and wear on other components.

In addition to its structural role, the Subbase is also involved in the thermal management of the engine. It acts as a conduit for heat dissipation, helping to maintain optimal operating temperatures for the engine’s internal components. This is achieved through its integration with cooling systems and heat sinks, which are often mounted on or near the Subbase.

Overall, the 3046108 Subbase is a key component that underpins the functionality and reliability of engine systems. Its role in supporting the Base Rail, managing forces, and aiding in thermal management makes it an indispensable part of the engine’s design.

Conclusion

The Cummins 3046108 Subbase is a vital component in commercial trucks, contributing to the efficiency, reliability, and longevity of the vehicle’s mechanical system. Its role in providing a stable platform for critical components, managing forces, and aiding in thermal management underscores its importance in engine systems. Proper installation, maintenance, and understanding of its function are essential for fleet operators and mechanics to ensure optimal performance and cost-effectiveness in truck operations.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.