This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Air Inlet Tube, part number 3045579, is a component manufactured by Cummins, a renowned name in diesel engines and related components. This inlet tube is specifically designed for use in heavy-duty trucks, where it plays a significant role in the operation of the air compressor system. Understanding its function and importance can provide valuable insights into the maintenance and efficiency of heavy-duty truck operations.

Function and Operation

The Compressor Air Inlet Tube is integral to the air compressor system in heavy-duty trucks. It facilitates the intake of air into the compressor, where it is pressurized before being distributed throughout the truck’s systems. The tube is positioned to draw in ambient air, which is then directed into the compressor. Its design ensures a smooth and efficient airflow, which is crucial for the compressor’s operation 1.

Key Features

This Cummins part is constructed from durable materials, ensuring it can withstand the rigors of heavy-duty truck environments. Its design includes features that enhance airflow efficiency and reduce the risk of blockages. The tube is also engineered to fit precisely within the truck’s compressor system, ensuring a secure and effective connection 2.

Role in Truck Operation

In the operation of a heavy-duty truck, the Compressor Air Inlet Tube contributes to the efficiency and performance of the air compressor system. By ensuring a consistent and unobstructed airflow into the compressor, it helps maintain the system’s pressure levels, which are vital for various truck functions, including braking systems and pneumatic controls 3.

Benefits

Using the Compressor Air Inlet Tube offers several benefits. Its design promotes improved airflow, which can enhance the overall efficiency of the air compressor system. The tube’s durable construction ensures reliability and longevity, contributing to the truck’s performance and reducing the need for frequent replacements 4.

Installation Considerations

Proper installation of the Compressor Air Inlet Tube is important for its optimal performance and longevity. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and efficient operation within the compressor system. Attention to detail during installation can prevent issues that may arise from improper fitting 5.

Maintenance and Troubleshooting

Regular maintenance of the Compressor Air Inlet Tube is recommended to ensure its continued efficiency and durability. This includes checking for any signs of wear or damage and ensuring there are no obstructions in the airflow path. Common issues may include blockages or leaks, which can often be addressed through routine inspections and cleaning 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, including diesel and natural gas, as well as related technologies, including fuel systems, emissions solutions, and engine-related components. With a history of innovation and a strong reputation in the industry, Cummins is known for its commitment to quality and performance in the components it produces 7.

Role of Part 3045579 Compressor Air Inlet Tube in Engine Systems

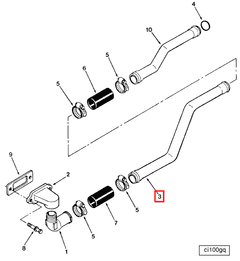

The Compressor Air Inlet Tube, designated as part 3045579, is integral to the efficient operation of various engine systems. It serves as a conduit for directing ambient air into the compressor section of the engine.

Interaction with Key Components

-

Air Inlet: The journey of air into the engine begins at the air inlet. This is where external air is drawn into the engine system. The Compressor Air Inlet Tube is strategically positioned to channel this airflow seamlessly from the air inlet towards the compressor.

-

Compressor: Once the air reaches the compressor, it undergoes a significant increase in pressure. The Compressor Air Inlet Tube ensures a steady and uninterrupted supply of air to the compressor, which is essential for the compressor’s function of pressurizing the air before it enters the combustion chamber.

-

Compressor Air Inlet: This component is the direct interface between the Compressor Air Inlet Tube and the compressor. The tube’s design and placement are optimized to align perfectly with the compressor air inlet, ensuring that air is delivered efficiently without turbulence or loss of pressure.

-

Arrangement: The overall arrangement of these components is meticulously planned to maximize engine performance. The Compressor Air Inlet Tube plays a pivotal role in this arrangement by ensuring that the air path from the air inlet to the compressor is as direct and unobstructed as possible.

Conclusion

In summary, the Compressor Air Inlet Tube (part 3045579) is a key element in the air induction system of engine components. Its proper function and integration with other components like the air inlet, compressor, and compressor air inlet are essential for the optimal performance of the engine.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411333.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411333.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.