This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3036576 Pyrometer is a specialized temperature monitoring device designed for use in commercial trucks. Its purpose is to accurately measure the temperature of exhaust gases, providing valuable data that contributes to the efficient and safe operation of the vehicle. This part is significant in the context of truck operations as it helps in maintaining optimal engine performance and ensuring the longevity of the engine components.

Basic Concepts of Pyrometers

A pyrometer is an instrument used to measure high temperatures. It operates by detecting the thermal radiation emitted by an object and converting this radiation into a temperature reading. Pyrometers are utilized across various industries for temperature monitoring in processes and equipment. In the context of commercial trucks, pyrometers play a vital role in monitoring exhaust gas temperatures, which is crucial for engine diagnostics and performance optimization 1.

Purpose of the Cummins 3036576 Pyrometer

The Cummins 3036576 Pyrometer is designed to monitor the temperature of exhaust gases in commercial trucks. By providing real-time temperature data, it allows for the assessment of engine performance and the detection of potential issues such as overheating or inefficient combustion. This monitoring capability is integral to maintaining the engine’s operational efficiency and preventing damage from excessive temperatures 2.

Key Features

The Cummins 3036576 Pyrometer is characterized by several key features that enhance its functionality and reliability. These include high accuracy in temperature readings, robust construction for durability in harsh operating environments, and seamless integration capabilities with truck diagnostic and monitoring systems. These features ensure that the pyrometer provides reliable data and can be easily incorporated into existing truck systems 3.

Benefits of Using the Cummins 3036576 Pyrometer

Employing the Cummins 3036576 Pyrometer in truck operations offers several advantages. It contributes to improved engine performance by enabling precise temperature monitoring, which is crucial for optimal combustion and efficiency. Additionally, it enhances safety by alerting operators to potential overheating issues before they become critical. Efficient maintenance scheduling is another benefit, as the pyrometer’s data can help in predicting maintenance needs and preventing unexpected breakdowns.

Installation and Integration

Proper installation and integration of the Cummins 3036576 Pyrometer into truck systems are crucial for ensuring optimal performance and accuracy. Installation guidelines typically include selecting an appropriate location for the sensor, ensuring proper alignment and secure mounting, and connecting the pyrometer to the truck’s diagnostic system. Following these guidelines ensures that the pyrometer operates effectively and provides accurate temperature readings.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3036576 Pyrometer include sensor malfunctions, inaccurate readings, and integration problems with the truck’s system. Troubleshooting tips involve checking the sensor’s alignment and connection, calibrating the pyrometer, and ensuring that it is compatible with the truck’s diagnostic software. Regular maintenance practices, such as cleaning the sensor and inspecting the wiring, are important for ensuring the longevity and reliable operation of the pyrometer.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins is committed to innovation and sustainability in the automotive industry. The company’s product range includes engines and components for on-highway and off-highway applications, demonstrating its versatility and expertise in power solutions.

Role of Part 3036576 Pyrometer in Engine Systems

The 3036576 Pyrometer is an essential component in monitoring and maintaining the operational integrity of engine systems. It is strategically integrated into various components to ensure accurate temperature readings and efficient engine performance.

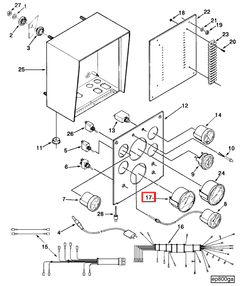

Integration with the Instrument Panel

The Pyrometer is mounted on the Instrument Panel, providing real-time temperature data directly to the operator. This integration allows for immediate feedback on engine temperature, enabling prompt responses to any anomalies.

Connection to the Engine Instrument

By linking the Pyrometer to the Engine Instrument, it enhances the overall monitoring capabilities of the engine system. This connection ensures that temperature data is consistently recorded and displayed, contributing to better engine management.

Placement within the Belt Guard

Incorporating the Pyrometer within the Belt Guard protects it from physical damage while still allowing it to accurately measure temperatures in critical engine areas. This placement is vital for maintaining the durability and reliability of the Pyrometer.

Instrument Panel Mounting

The Pyrometer is often part of the Instrument Panel Mounting system, which secures it in place for stable and accurate readings. This mounting ensures that the Pyrometer remains in an optimal position to monitor engine temperatures effectively.

Interaction with the Panel Instrument

The Pyrometer works in conjunction with the Panel Instrument to provide a comprehensive view of engine performance. This interaction allows for a more detailed analysis of engine conditions, facilitating better maintenance practices.

Conclusion

In summary, the Cummins 3036576 Pyrometer plays a significant role in enhancing the monitoring and maintenance of engine systems through its integration with various components such as the Instrument Panel, Engine Instrument, Belt Guard, Instrument Panel Mounting, and Panel Instrument. Its accurate temperature readings contribute to improved engine performance, safety, and efficient maintenance scheduling.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.