This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

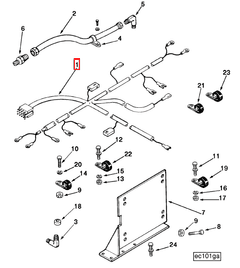

The Cummins 3035720 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This part is significant in ensuring the reliable operation of the truck’s electrical systems, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath or conduit, to prevent damage and reduce electromagnetic interference. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for distributing power and signals to various components, ensuring efficient and reliable operation 1.

Purpose of the 3035720 Wiring Harness

The Cummins 3035720 Wiring Harness is designed to integrate with the electrical systems of commercial trucks, providing a reliable pathway for electrical power and signals. It connects critical components such as sensors, actuators, and control modules, enabling them to communicate and operate in unison. This integration is vital for the proper functioning of the truck’s engine management, lighting, instrumentation, and other electrical systems 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, which contribute to its performance and durability. It is constructed using corrosion-resistant materials and is designed to withstand the harsh conditions often encountered in commercial truck operations. Unique characteristics of this wiring harness include its precise engineering to fit specific truck models and its ability to reduce electrical noise, ensuring clear signal transmission.

Benefits

The use of the Cummins 3035720 Wiring Harness offers several advantages in truck operations. It enhances the efficiency of the electrical system by providing a direct and secure connection between components. This reliability reduces the likelihood of electrical failures, contributing to safer and more dependable truck performance. Additionally, the harness’s design helps in maintaining the integrity of electrical signals, which is crucial for the accurate operation of the truck’s systems 3.

Installation Considerations

When installing the Cummins 3035720 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. This may include checking for compatibility with the truck model, ensuring all connections are secure, and using any special tools required for installation. Adhering to these practices helps in achieving a successful installation that meets the truck’s operational requirements.

Troubleshooting Common Issues

Frequent problems associated with wiring harnesses can include loose connections, damaged wires, or corrosion. To resolve these issues, a systematic approach is recommended. This involves inspecting the harness for visible damage, ensuring all connections are tight and secure, and cleaning or replacing corroded components as necessary. Addressing these issues promptly helps in maintaining the reliability and safety of the truck’s electrical system.

Maintenance Tips

Regular maintenance practices are key to ensuring the longevity and optimal performance of the Cummins 3035720 Wiring Harness. This includes periodic inspections for signs of wear or damage, ensuring connections remain secure, and protecting the harness from environmental factors that could lead to corrosion or degradation. Adhering to these maintenance tips helps in preserving the integrity of the electrical system.

Safety Precautions

When working with the Cummins 3035720 Wiring Harness, observing important safety measures is crucial to prevent accidents and ensure personal safety. This includes disconnecting the battery before beginning any work on the electrical system, using insulated tools to avoid electrical shocks, and wearing appropriate personal protective equipment. These precautions are vital for safe and effective maintenance and repair work.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 3035720 Wiring Harness, which is designed to meet the demanding requirements of commercial truck operations.

Role of Part 3035720 Wiring Harness in Instrument Panel Mounting Systems

The 3035720 Wiring Harness is a component in the electrical architecture of modern engine systems, particularly in relation to the Instrument Panel Mounting (Inst. Panel Mtg.) systems. This wiring harness facilitates the electrical connections required for the proper functioning of the instrument panel, which is a central component in the vehicle’s dashboard.

Integration with Instrument Panel Mounting

-

Electrical Connectivity: The wiring harness ensures that all electrical components within the instrument panel receive the necessary power and signals. This includes connections to gauges, warning lights, and control modules that are mounted on the instrument panel.

-

Signal Transmission: It acts as a conduit for transmitting signals from various sensors and control units to the instrument panel. This allows for real-time data display, such as engine temperature, fuel level, and other vital metrics.

-

Grounding and Stability: The harness provides essential grounding paths, which are vital for the stable operation of electronic components. Proper grounding helps in reducing electrical noise and ensures accurate signal transmission.

-

Modular Design: The modular nature of the wiring harness allows for easy integration with other components within the instrument panel mounting system. This modularity aids in simplifying the installation process and allows for easier troubleshooting and maintenance.

-

Safety Features: Incorporated within the harness are safety features such as fuses and circuit breakers. These components protect the electrical system from overloads and short circuits, enhancing the overall safety of the engine system.

-

Compatibility with Control Units: The wiring harness is designed to interface seamlessly with various control units, including the Engine Control Unit (ECU) and Body Control Module (BCM). This integration ensures that the instrument panel can communicate effectively with these units, providing comprehensive vehicle diagnostics and status updates.

Conclusion

In summary, the 3035720 Wiring Harness plays a significant role in ensuring the reliable and efficient operation of the instrument panel mounting system within engine systems. Its design and functionality are tailored to support the complex electrical requirements of modern vehicles, contributing to both performance and safety.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Duffy, Owen C., and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Han, Zhiyu. Simulation and Optimization of Internal Combustion Engines. SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.