This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

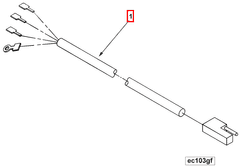

The Cummins 3035124 Wiring Harness is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the electrical connections necessary for the operation of various truck systems. This part is significant in ensuring the reliable and efficient performance of the truck’s electrical system.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and terminals that transmit electrical power and signals between different components of a vehicle. It simplifies the installation process and reduces the risk of electrical faults. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for routing electrical connections, ensuring that power and data are transmitted efficiently and safely 1.

Role of the 3035124 Wiring Harness in Truck Operation

This Cummins part is integral to the electrical system of a truck. It connects various electrical components, such as sensors, actuators, and control modules, allowing them to communicate and function together. This harness interacts with the truck’s engine control unit (ECU), transmission, and other critical systems, ensuring that electrical signals are accurately transmitted and received.

Key Features of the 3035124 Wiring Harness

The 3035124 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that can withstand the harsh conditions often encountered in commercial trucking. Unique characteristics include its resistance to vibration, extreme temperatures, and corrosion, which contribute to its longevity and reliability.

Benefits of Using the 3035124 Wiring Harness

Utilizing this part offers several advantages. It enhances the reliability of the truck’s electrical system by providing secure and consistent connections. Additionally, it improves efficiency by reducing the likelihood of electrical faults and minimizing the need for repairs. Safety is also increased, as a well-maintained wiring harness reduces the risk of electrical fires and other hazards 2.

Installation Considerations

When installing the 3035124 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration into the truck’s electrical system. This may include verifying that all connections are secure, using appropriate tools for installation, and ensuring that the harness is routed away from moving parts and heat sources. Special tools or prerequisites may be required, depending on the specific truck model.

Maintenance and Troubleshooting

Maintaining the 3035124 Wiring Harness involves regular inspections to check for signs of wear, corrosion, or damage. Troubleshooting common issues may require identifying loose connections, damaged wires, or faulty connectors. Recommended solutions include repairing or replacing damaged sections of the harness and ensuring that all connections are clean and secure.

Compatibility and Applications

The 3035124 Wiring Harness is designed for use in specific types of trucks and engines. It is suited for applications where reliable and efficient electrical connections are critical to the operation of the vehicle. Detailed information on compatibility and specific applications will be provided separately.

Safety Considerations

When working with the 3035124 Wiring Harness, it is important to adhere to safety guidelines and practices. This includes ensuring that the truck’s battery is disconnected before beginning any work on the electrical system, using insulated tools to prevent short circuits, and wearing appropriate personal protective equipment (PPE). Electrical safety practices are crucial to prevent injuries and ensure the safe operation of the vehicle 3.

Cummins Corporation Overview

Cummins Corporation is a leading manufacturer of diesel and natural gas engines, as well as related technologies. With a history of innovation and commitment to quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s focus on developing reliable and efficient components, such as the 3035124 Wiring Harness, underscores its dedication to enhancing the performance and safety of commercial vehicles.

Cummins Wiring Harness 3035124 Compatibility with Various Engines

The Cummins Wiring Harness part number 3035124 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to fit specific models, providing a robust solution for maintaining the electrical systems of these engines.

K19 and K38 Engines

The K19 and K38 engines are part of Cummins’ lineup of mid-range diesel engines, often utilized in various industrial and commercial applications. The 3035124 wiring harness is meticulously crafted to match the electrical architecture of these engines, ensuring compatibility and ease of installation.

K50 and N14 MECHANICAL Engines

The K50 engine, known for its durability and efficiency, is commonly found in heavy-duty applications. Similarly, the N14 MECHANICAL engine is a robust choice for demanding environments. The 3035124 wiring harness is engineered to fit these engines, providing a reliable electrical connection that supports the engine’s operational needs.

NH/NT 855 Engines

The NH/NT 855 engines are part of Cummins’ range of high-performance diesel engines, often used in agricultural and construction machinery. The 3035124 wiring harness is designed to integrate with these engines, ensuring that the electrical systems are properly connected and functioning optimally.

V28 Engine

The V28 engine is another high-performance model in Cummins’ portfolio, typically used in heavy-duty applications. The 3035124 wiring harness is compatible with the V28 engine, providing a dependable solution for maintaining the engine’s electrical systems.

Role of Part 3035124 Wiring Harness in Engine Systems

The 3035124 Wiring Harness is integral to the efficient operation of various engine systems. It serves as the primary conduit for electrical signals and power, ensuring seamless communication and functionality among different components.

Integration with Adapter Wiring Harness

When integrated with an adapter wiring harness, the 3035124 Wiring Harness facilitates the connection between aftermarket components and the vehicle’s native electrical system. This setup allows for the smooth transfer of data and power, enabling the adapter to function correctly without requiring extensive rewiring or modifications.

Interaction with Switch Components

In systems involving switches, the 3035124 Wiring Harness plays a key role in transmitting signals from the switch to the corresponding actuators or control units. Whether it’s an ignition switch, a starter switch, or auxiliary switches for lighting and accessories, the wiring harness ensures that the switch’s command is accurately and promptly relayed to the intended component.

Coordination with Coolant Level Sensor

For coolant level monitoring, the 3035124 Wiring Harness connects the coolant level sensor to the engine control unit (ECU). This connection allows the ECU to receive real-time data on the coolant level, enabling it to make necessary adjustments to the engine’s operation to maintain optimal performance and prevent overheating. The wiring harness ensures that the sensor’s readings are accurately transmitted, contributing to the engine’s overall reliability and efficiency.

Conclusion

The Cummins 3035124 Wiring Harness is a critical component in the electrical systems of commercial trucks and Cummins engines. Its robust design, compatibility with various engine models, and role in ensuring reliable electrical connections make it an essential part for maintaining the performance and safety of these vehicles. Proper installation, maintenance, and adherence to safety practices are vital to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.