This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

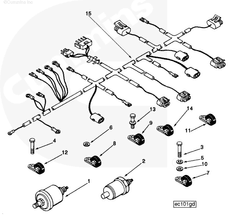

The Cummins 3035120 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety .

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in distributing power and signals to components such as lights, sensors, and control units, ensuring they operate correctly .

Purpose of the 3035120 Wiring Harness

The Cummins 3035120 Wiring Harness is designed to integrate seamlessly with a truck’s electrical system, providing a structured and organized method for routing electrical connections. It plays a role in connecting the truck’s battery to various electrical components, including the engine control module, sensors, and lighting systems. This integration ensures that electrical signals and power are efficiently distributed throughout the vehicle, supporting the operation of critical systems and enhancing overall functionality .

Key Features

The Cummins 3035120 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable insulation materials to protect the wires from abrasion and environmental conditions. The harness features precise connector placements to ensure secure and reliable connections. Additionally, it is designed to withstand the vibrations and harsh conditions typical of commercial truck operations, enhancing its performance and longevity.

Benefits

The use of the Cummins 3035120 Wiring Harness offers several advantages in truck operations. It contributes to improved efficiency by ensuring reliable electrical connections, reducing the risk of power loss or signal interference. The harness enhances reliability by providing a structured and organized method for routing electrical connections, minimizing the potential for errors during installation or maintenance. Furthermore, it plays a role in safety by ensuring that electrical components receive the correct voltage and signals, reducing the risk of malfunctions that could lead to accidents.

Installation Considerations

Proper installation of the Cummins 3035120 Wiring Harness is crucial for ensuring its effectiveness and longevity. Installation should be performed by qualified technicians familiar with the truck’s electrical system. It may require the use of specialized tools to ensure secure connections and proper routing of the harness. Attention to detail during installation helps prevent issues such as loose connections or damage to the harness, which could affect the truck’s electrical performance.

Troubleshooting Common Issues

Common issues with wiring harnesses can include loose connections, damaged wires, or faulty connectors. Troubleshooting these issues involves inspecting the harness for visible damage, ensuring all connections are secure, and testing the electrical continuity of the wires. Addressing these problems promptly helps maintain the integrity of the truck’s electrical system and prevents potential safety hazards.

Maintenance Tips

Regular maintenance of the Cummins 3035120 Wiring Harness is important for ensuring its longevity and optimal performance. This includes inspecting the harness for signs of wear or damage, ensuring all connections are secure, and protecting the harness from physical damage and environmental factors. Routine checks and maintenance help identify potential issues before they lead to more significant problems, contributing to the overall reliability of the truck’s electrical system.

Safety Precautions

When working with the Cummins 3035120 Wiring Harness, it is important to observe safety precautions to prevent accidents and ensure personal safety. This includes disconnecting the battery before beginning any work on the electrical system, using insulated tools to avoid short circuits, and wearing appropriate personal protective equipment. Adhering to these safety measures helps protect both the technician and the vehicle’s electrical system during maintenance or repair procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the diverse needs of its customers, contributing to the efficiency, performance, and safety of commercial vehicles worldwide.

Role of Part 3035120 Wiring Harness in Engine Systems

The part 3035120 Wiring Harness is an integral component in the engine wiring system, facilitating the seamless transmission of electrical power and signals between various engine components. Its design ensures efficient and reliable operation of the engine by connecting critical systems such as the ignition, fuel injection, sensors, and control modules.

Integration with Engine Components

- Ignition System: The wiring harness provides the necessary connections for the ignition coil, spark plugs, and ignition control module. This ensures that the ignition system receives the correct voltage and timing signals to generate the spark needed for combustion.

- Fuel Injection System: It links the fuel injectors to the engine control unit (ECU), allowing for precise fuel delivery based on engine load, speed, and other operating conditions. This connection is vital for maintaining optimal fuel efficiency and performance.

- Sensors and Actuators: The harness connects various sensors (such as the oxygen sensor, mass airflow sensor, and throttle position sensor) to the ECU. These sensors provide real-time data that the ECU uses to adjust engine parameters. Additionally, it powers actuators like the idle air control valve and variable valve timing solenoid.

- Starting System: It includes connections for the starter motor and solenoid, enabling the engine to crank and start. The harness ensures that the starter receives the appropriate voltage from the battery.

- Charging System: The wiring harness connects the alternator to the battery and electrical system, allowing for the generation and distribution of electrical power while the engine is running.

- Grounding: It provides essential grounding connections to ensure that all electrical components operate within a common electrical potential, reducing the risk of electrical noise and ensuring stable operation.

- Accessory Power: The harness also supplies power to various engine accessories such as the water pump (in electric models), oil pressure sensor, and temperature gauge, ensuring these components function correctly.

By efficiently managing these connections, the part 3035120 Wiring Harness plays a significant role in the overall performance, reliability, and durability of the engine system.

Conclusion

The Cummins 3035120 Wiring Harness is a critical component in the electrical systems of commercial trucks and engines. Its robust design, high-quality materials, and precise engineering ensure reliable and efficient operation of the vehicle’s electrical systems. Proper installation, maintenance, and adherence to safety precautions are essential for maximizing the performance and longevity of this Cummins part. The integration of this wiring harness with various engine components underscores its importance in ensuring the overall functionality and safety of the vehicle.

: Daniel Williams, *Generalized Vehicle Dynamics*, SAE International, 2022.

: John Kasab and Andrea Strzelec, *Automotive Emissions Regulations and Exhaust Aftertreatment Systems*, SAE International, 2020.

: Cummins Inc., *X11 CM2670 X126B Service Manual (5504465)*.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.