3035084

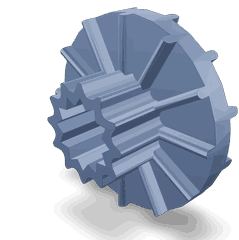

Vibration Isolator

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3035084 Vibration Isolator is a component designed to mitigate mechanical vibrations in heavy-duty truck operations. Its role is to enhance the stability and efficiency of the truck’s engine and drivetrain by reducing the transmission of vibrations from the engine to the truck’s frame and other components.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used in mechanical systems to minimize the transmission of vibrations from one part of a system to another. They function by absorbing or dampening vibrations, thereby protecting sensitive components from the adverse effects of excessive vibration. In the context of heavy-duty trucks, vibration isolators play a role in maintaining the integrity of the engine and drivetrain, as well as improving driver comfort and potentially enhancing fuel efficiency 1.

Purpose of the Cummins 3035084 Vibration Isolator

The Cummins 3035084 Vibration Isolator is specifically designed to reduce mechanical vibrations in heavy-duty trucks. By isolating the engine from the truck’s frame, it helps to minimize the impact of engine vibrations on other components, thereby contributing to the overall stability and performance of the vehicle. This reduction in vibration can lead to decreased wear on engine mounts and other components, as well as a smoother ride for the driver 2.

Key Features

The Cummins 3035084 Vibration Isolator features a robust design that includes high-quality materials to ensure durability and effectiveness. Its construction may incorporate elastomeric materials that provide excellent vibration dampening properties. Additionally, the isolator is designed to be compatible with specific engine models, ensuring a precise fit and optimal performance. Unique characteristics such as its ability to withstand high temperatures and resist degradation over time further enhance its performance in demanding environments 3.

Benefits of Using the Cummins 3035084 Vibration Isolator

Utilizing the Cummins 3035084 Vibration Isolator offers several advantages. It contributes to improved equipment longevity by reducing the wear and tear on engine mounts and other components. Enhanced driver comfort is another benefit, as the isolator helps to create a smoother ride by minimizing engine vibrations. Additionally, by stabilizing the engine and reducing vibrations, the isolator may play a role in achieving potential fuel efficiency gains, as a stable engine can operate more efficiently 4.

Installation Considerations

Proper installation of the Cummins 3035084 Vibration Isolator is crucial for its effective performance. It is recommended to follow manufacturer guidelines for installation, which may include preparatory steps such as cleaning the mounting surfaces and ensuring that all components are free from debris. The use of appropriate tools and equipment is also important to ensure a secure and proper fit. Careful attention to detail during installation can help to maximize the isolator’s effectiveness and longevity.

Troubleshooting Common Issues

Frequent problems associated with vibration isolators can include excessive wear, degradation of the isolator material, or improper installation. Potential causes may range from normal wear and tear to environmental factors such as exposure to extreme temperatures or chemicals. Recommended troubleshooting steps include regular inspection for signs of wear or damage, ensuring proper installation, and replacing the isolator if it shows signs of degradation or failure.

Maintenance Tips

Routine maintenance practices are important to ensure the longevity and effectiveness of the Cummins 3035084 Vibration Isolator. Regular inspections should be conducted to check for signs of wear, damage, or degradation. Replacement guidelines may vary depending on the specific conditions of use, but it is generally recommended to replace the isolator if it shows significant signs of wear or if it has been in service for an extended period. Keeping the isolator clean and free from debris can also help to maintain its performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established itself as a key player in the automotive and heavy-duty truck industry. The company is known for its commitment to innovation, quality, and customer satisfaction, providing a wide range of products and services that meet the needs of customers around the world.

Cummins Vibration Isolator 3035084 Compatibility

The Cummins Vibration Isolator part number 3035084 is a critical component designed to mitigate vibrations in various engine systems. This part is engineered to fit seamlessly with a range of Cummins engines, ensuring optimal performance and longevity. Below is a detailed overview of its compatibility with different engine models:

Small Bore Engines

- 6C8.3

- G8.3

These compact engines benefit from the vibration isolator to maintain smooth operation and reduce wear and tear.

Medium Bore Engines

- K19

- K38

- K50

- KTA19GC CM558

- KTA38GC CM558

Medium bore engines such as the K series and KTA series utilize the vibration isolator to enhance operational stability and efficiency.

High Bore Engines

- M11 MECHANICAL

- N14 MECHANICAL

- NH/NT 855

Larger mechanical engines like the M11 and N14 series depend on the vibration isolator to manage the increased stress and vibrations associated with their size and power.

QSK Series Engines

- QSK19 CM2350 K114

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60 G CM2358 K110

- QSK60G

- QSK78 CM500

- QSK95 CM2350 K111

The QSK series encompasses a wide range of high-performance engines, all of which are compatible with the vibration isolator. This compatibility ensures that these powerful engines operate smoothly, reducing the risk of damage from excessive vibrations.

By integrating the Cummins Vibration Isolator 3035084 into these engines, users can expect improved performance, reduced maintenance costs, and enhanced reliability across the board.

Role of Part 3035084 Vibration Isolator in Engine Systems

The Part 3035084 Vibration Isolator is integral to maintaining the operational integrity and efficiency of various engine systems. It effectively mitigates the transmission of vibrations from the engine to other components, ensuring smooth and reliable performance.

Integration with Key Components

Aftercooler Mounting

The Vibration Isolator is employed in the aftercooler mounting to reduce the vibrational impact on the aftercooler. This ensures consistent cooling performance and prolongs the lifespan of the aftercooler.

Alternator Systems

In alternator systems, including the alternator belt guard, alternator bracket kit, and alternator guard mounting, the Vibration Isolator minimizes the vibrational stress on the alternator. This results in stable electrical output and reduced wear on the alternator components.

Compressor and Refrigerant Systems

For compressor and refrigerant systems, the Vibration Isolator is used to dampen vibrations that could otherwise affect the compressor’s efficiency and the integrity of refrigerant lines. This leads to more reliable cooling and consistent refrigerant flow.

Coolant and Heating Systems

In coolant aid heater and coolant heater plumbing, the Vibration Isolator helps in maintaining the structural integrity of the plumbing and heating elements. It prevents vibrations from causing leaks or damage to the coolant system, ensuring efficient heat transfer and system reliability.

Cooling System and Gaskets

Within the cooling system gasket kit, the Vibration Isolator plays a role in protecting gaskets from vibrational damage. This ensures that the cooling system remains sealed and operates efficiently, preventing overheating and system failures.

Dampers and Drive Systems

The Vibration Isolator works in conjunction with dampers and drive systems, such as the damper vibration and drive alternator, to provide a smoother operation. This reduces the likelihood of mechanical failures and enhances the overall performance of the drive system.

Enclosure and Instrument Panels

For enclosure mounting brackets, instrument panel enclosures, and instruction panel mounting, the Vibration Isolator ensures that these components remain securely in place without being adversely affected by engine vibrations. This is vital for the accurate reading of instruments and the structural integrity of enclosures.

Starting Motor and Mounting Brackets

In starting motor and mounting bracket applications, the Vibration Isolator helps in reducing the vibrational impact on the starting motor. This ensures reliable starts and extends the lifespan of the starting motor.

Wiring and Performance Parts

Finally, in wiring harnesses and performance parts, the Vibration Isolator protects electrical connections and performance components from vibrational damage. This ensures consistent performance and reliability of the engine’s electrical systems.

By effectively isolating vibrations, Part 3035084 contributes to the enhanced performance, durability, and reliability of various engine systems and components.

Conclusion

The Cummins 3035084 Vibration Isolator is a vital component in the maintenance and optimization of heavy-duty truck engines. By effectively reducing mechanical vibrations, it enhances the stability, efficiency, and longevity of the engine and drivetrain. Its robust design, compatibility with various Cummins engines, and integration with key engine components underscore its importance in ensuring smooth operation and reliable performance. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to improved driver comfort, potential fuel efficiency gains, and reduced maintenance costs.

-

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.