This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

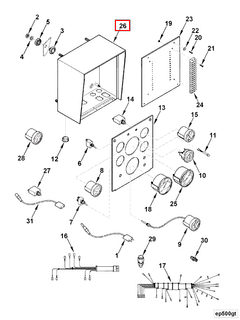

The Cummins 3034162 Instrument Cabinet is a critical component for commercial trucks, designed to house and protect essential instrumentation and controls. This part ensures that drivers have access to necessary information and functionalities while operating their vehicles.

Purpose and Functionality

The Instrument Cabinet is integral to a truck’s operation by providing a secure and organized environment for the vehicle’s instrumentation. It protects gauges, switches, and other controls from external elements, such as vibrations, moisture, and physical impacts, which could otherwise impair their function. This protection is vital for maintaining the accuracy and reliability of the readings and controls that drivers depend on for safe and efficient operation 1.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials. Its construction is aimed at ensuring durability and longevity, even in the demanding conditions often encountered by commercial trucks. The cabinet is designed to be both functional and easy to access, allowing for straightforward installation and maintenance. Additionally, its design may include features that enhance ventilation and reduce the risk of overheating, contributing to the overall performance and reliability of the housed instruments 2.

Benefits

Utilizing the Cummins 3034162 Instrument Cabinet offers several advantages. It enhances driver visibility by providing a clear and organized display of critical information. The protection it offers to instruments helps in maintaining their accuracy and longevity. Furthermore, its durable construction ensures that it can withstand the harsh environments typical of commercial trucking, contributing to the overall reliability and safety of the vehicle.

Installation

Proper installation of the Instrument Cabinet involves several steps to ensure it is securely and correctly fitted. This process may require specific tools and adherence to manufacturer guidelines to avoid damage to the cabinet or the instruments it houses. It is important to follow the installation instructions carefully to ensure that the cabinet is properly secured and that all connections are correctly made.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3034162 Instrument Cabinet is important for ensuring its longevity and optimal performance. This may include checking for signs of wear or damage, ensuring that all connections are secure, and cleaning the cabinet to remove any dirt or debris that could affect its function. Common issues may include loose connections or damaged components, which can often be addressed through simple repairs or replacements.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its high-quality engines and components. With a history of innovation and commitment to excellence, Cummins has built a reputation for reliability and performance. The company’s products, including the Cummins 3034162 Instrument Cabinet, are designed with the aim of enhancing the efficiency, safety, and durability of commercial trucks.

Compatibility with Various Engines

The Cummins Instrument Cabinet, part number 3034162, is designed to integrate seamlessly with a range of Cummins engines, providing a centralized control and monitoring system. This part is engineered to enhance the operational efficiency and reliability of the engines it is paired with. Below is a detailed overview of its compatibility with specific engine models:

K19, K38, and K50 Engines

The Cummins Instrument Cabinet 3034162 is compatible with the K19, K38, and K50 engines. These engines are known for their robust performance and are widely used in various industrial applications. The instrument cabinet ensures that operators have easy access to critical engine data and controls, facilitating better management and maintenance of these engines.

N14 MECHANICAL Engine

The N14 MECHANICAL engine benefits from the integration of the Cummins Instrument Cabinet 3034162. This engine is renowned for its durability and efficiency, making it a popular choice in heavy-duty applications. The instrument cabinet provides a user-friendly interface for monitoring engine parameters, ensuring optimal performance and longevity.

NH/NT 855 Engines

The Cummins Instrument Cabinet 3034162 is also designed to work with the NH/NT 855 engines. These engines are known for their versatility and are used in a variety of sectors, including agriculture and construction. The instrument cabinet enhances the operational capabilities of these engines by providing comprehensive monitoring and control features.

V28 Engine

The V28 engine is another model that can be effectively paired with the Cummins Instrument Cabinet 3034162. This engine is recognized for its power and efficiency, making it suitable for demanding applications. The instrument cabinet ensures that operators can easily monitor and manage the engine’s performance, contributing to its overall reliability and efficiency.

By integrating the Cummins Instrument Cabinet 3034162 with these engines, operators can benefit from improved control, enhanced monitoring capabilities, and easier maintenance, ultimately leading to better performance and longevity of the engines.

Role of Part 3034162 Instrument Cabinet in Engine Systems

The Instrument Cabinet is an integral component in the orchestration of various engine systems, providing a structured and secure environment for the instrumentation that monitors and controls engine performance.

Integration with Engine Instrumentation

The Instrument Cabinet houses the Instrument Panel, which is the central hub for the Engine Instrument displays and controls. This panel is typically enclosed within an Instrument Panel Enclosure to protect sensitive gauges and readouts from environmental factors such as vibration, moisture, and dust. The enclosure is often part of a larger Enclosure system that may include a Belt Guard to shield moving parts and prevent accidental contact.

Functional Synergy

Within the cabinet, the Instrument Panel Enclosure ensures that the Instrument Panel remains intact and functions correctly under operational conditions. This enclosure is designed to be robust yet accessible, allowing for easy maintenance and calibration of the instruments it protects.

The Panel itself is a compilation of various gauges and indicators that provide real-time data on engine parameters such as temperature, pressure, and RPM. These readings are essential for the operator to make informed decisions regarding engine operation and maintenance.

Enhanced Operational Efficiency

By integrating the Instrument Cabinet with the engine systems, engineers and mechanics can ensure that all instrumentation is systematically organized, easily accessible, and well-protected. This setup not only enhances the operational efficiency of the engine but also contributes to the longevity and reliability of the instrumentation itself.

Conclusion

In summary, the Cummins 3034162 Instrument Cabinet plays a significant role in maintaining the integrity and functionality of engine instrumentation, ensuring that all components work in unison to provide accurate and timely information for engine management. Its robust design, compatibility with various Cummins engines, and the protection it offers to critical instrumentation make it a valuable component for commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.