This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3028324 Check Valve is a component designed to regulate fluid flow within the systems of commercial trucks. Its purpose is to allow fluid to flow in one direction while preventing reverse flow, which helps maintain system integrity and efficiency. This valve is significant in ensuring the proper operation of various truck systems by managing fluid dynamics effectively.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that permits fluid to flow through it in only one direction. It operates using a mechanism that opens when fluid flows in the correct direction and closes when the flow attempts to reverse. Check valves are commonly used in fluid systems to prevent backflow, which can cause system damage or inefficiency. Applications include water supply systems, fuel lines, and hydraulic systems 1.

Role of the 3028324 Check Valve in Truck Operation

The Cummins 3028324 Check Valve plays a specific role in the operation of commercial trucks by ensuring unidirectional fluid flow in critical systems. It is typically placed in the fuel or hydraulic systems where it supports functions such as fuel delivery and hydraulic pressure maintenance. By preventing backflow, it helps maintain system pressure and efficiency, ensuring that the truck operates smoothly and reliably.

Key Features

The Cummins 3028324 Check Valve is constructed from durable materials that enhance its performance and longevity. Its design includes a spring-loaded mechanism that ensures reliable operation under varying conditions. Unique attributes such as corrosion resistance and high-pressure tolerance contribute to its effectiveness in demanding truck environments 2.

Benefits of Using the 3028324 Check Valve

Utilizing the Cummins 3028324 Check Valve offers several advantages. It improves system efficiency by ensuring consistent fluid flow, which can lead to better overall truck performance. The valve’s reliability reduces the likelihood of system failures, contributing to increased uptime for fleet operators. Additionally, its durable construction can result in cost savings over time by minimizing the need for frequent replacements 3.

Installation Considerations

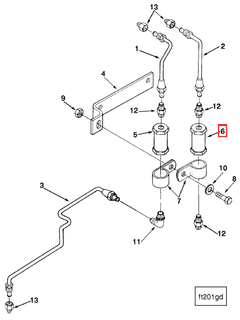

When installing the Cummins 3028324 Check Valve, it is important to follow guidelines to ensure proper function. This includes verifying that the valve is correctly oriented to allow fluid flow in the intended direction. Special tools may be required for installation, and it is advisable to consult the manufacturer’s instructions to ensure all prerequisites are met.

Troubleshooting Common Issues

Common problems associated with check valves include leakage and failure to open or close properly. Troubleshooting methods involve inspecting the valve for signs of wear or damage, checking the spring mechanism for proper function, and ensuring that there are no obstructions in the fluid path. Addressing these issues promptly can help maintain system efficiency and prevent more significant problems.

Maintenance Tips

Regular maintenance of the Cummins 3028324 Check Valve is crucial for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or corrosion, cleaning the valve to remove any debris, and verifying that the spring mechanism operates smoothly. Adhering to recommended inspection intervals and maintenance procedures will help sustain the valve’s effectiveness.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation.

Cummins Check Valve 3028324 Compatibility

The Cummins Check Valve 3028324 is designed to ensure the proper flow of fluids in various engine systems, preventing backflow and maintaining system integrity. This check valve is compatible with a range of Cummins engines, providing a reliable solution for maintaining optimal engine performance.

K19 and QSK19 CM500 Engines

The Check Valve 3028324 is suitable for use in the K19 and QSK19 CM500 engines. These engines are known for their robust design and high performance, often used in heavy-duty applications. The check valve ensures that the fluid flow within these engines remains unidirectional, which is crucial for maintaining the efficiency and longevity of the engine components.

L10 MECHANICAL and N14 MECHANICAL Engines

For the L10 MECHANICAL and N14 MECHANICAL engines, the Check Valve 3028324 is an essential component. These engines are typically used in applications requiring high torque and durability. The check valve helps maintain the integrity of the lubrication and cooling systems, preventing any backflow that could compromise engine performance.

M11 CELECT PLUS and M11 MECHANICAL Engines

The M11 CELECT PLUS and M11 MECHANICAL engines benefit from the use of the Check Valve 3028324. These engines are designed for versatility and efficiency, often used in both on-highway and off-highway applications. The check valve ensures that the fluid flow remains consistent, contributing to the overall reliability and performance of these engines.

V28, V903, VTA903 CM2250, and V105 Engines

The Check Valve 3028324 is also compatible with the V28, V903, VTA903 CM2250, and V105 engines. These engines are known for their power and efficiency, often used in demanding industrial and construction applications. The check valve plays a critical role in maintaining the fluid dynamics within these engines, ensuring that the systems operate smoothly and reliably.

By integrating the Check Valve 3028324 into these engines, users can expect enhanced performance, reduced maintenance needs, and improved overall engine longevity.

Role of Part 3028324 Check Valve in Engine Systems

The Part 3028324 Check Valve is an integral component in various engine systems, ensuring the unidirectional flow of fluids and gases. Its application spans across multiple subsystems, enhancing the efficiency and reliability of the engine.

Fuel System Integration

In the fuel system, the Check Valve is positioned within the Fuel Supply Plumbing to prevent backflow, ensuring a consistent fuel supply to the injectors. It works in conjunction with the Fuel Tube and Fuel Tube Mounting to maintain pressure integrity. The Fuel Check Valve and Fuel Drain Check Valve collaborate to manage fuel drainage, preventing contamination and ensuring clean fuel delivery. The Fuel Bypass Mounting and Fuel Bypass Tube Mounting further support this by providing alternative pathways for fuel flow when necessary.

Coolant and Heater Starting System

Within the Coolant Heater Starting system, the Check Valve is essential for maintaining the correct flow of coolant. It is integrated into the Bypass Tube Mounting to ensure that coolant circulates efficiently, aiding in engine warm-up and maintaining optimal operating temperatures. The Check Valve Assembly and Check Valve Drain Assembly work together to manage coolant levels and prevent backflow, which could lead to system inefficiencies.

Viscosity Sensor and EBM Systems

The Check Valve also plays a role in the Viscosity Sensor system, where it ensures accurate readings by maintaining consistent fluid flow. In the EBM (Electric Blower Motor) systems, the Check Valve is used within the EBM Tubing and EBM Valve to regulate air and fluid flow, enhancing the performance of the blower motor. The Drain Cock and Check Valve Mounting are crucial for draining excess fluids and maintaining system pressure.

Plumbing and Supply Systems

Across various Plumbing systems, including Fuel, Fuel Drain, Fuel Supply, and Injector plumbing, the Check Valve ensures that fluids move in the intended direction, preventing backflow that could disrupt system operations. The Supply Check Valve is particularly important in maintaining the integrity of the fuel supply line, ensuring that the engine receives a steady and clean fuel flow.

Kit Base & Depot Parts

In Kit Base & Depot Parts, the Check Valve is often included to ensure that pre-assembled systems function correctly from the outset. Its integration into these kits guarantees that all components work harmoniously, reducing the likelihood of installation errors and enhancing overall system performance.

Conclusion

The Cummins 3028324 Check Valve is a critical component in maintaining the efficiency and reliability of commercial truck systems. By ensuring unidirectional fluid flow, it prevents backflow and system damage, contributing to the smooth operation of various engine subsystems. Its durable construction and reliable performance make it a valuable asset for fleet operators, offering long-term cost savings and enhanced engine longevity.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Konrad Reif. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Alma Hillier. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.