3027507

Check Valve

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3027507 Check Valve is a component designed for use in commercial truck systems. Manufactured by Cummins Inc., a leader in the diesel engine market, this check valve serves a specific function within the truck’s fluid systems. Understanding its purpose and operation is key to maintaining the efficiency and reliability of commercial vehicles.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a movable element, such as a flap or a ball, that opens under the pressure of the fluid flowing in the correct direction and closes when the flow attempts to reverse. This mechanism prevents backflow, which can cause system inefficiency or damage. Check valves are commonly used in various fluid systems, including water, air, and fuel lines, to ensure that the fluid moves in the intended direction 1.

Purpose of the Cummins 3027507 Check Valve

The Cummins 3027507 Check Valve plays a role in the truck’s fluid systems by preventing reverse flow. This is particularly important in systems where backflow could lead to contamination or reduced efficiency. By ensuring that fluid only moves in the correct direction, the check valve helps maintain the integrity of the system and supports the overall performance of the truck 2.

Key Features

The Cummins 3027507 Check Valve is characterized by several key features that enhance its performance. Its design includes a durable housing made from high-quality materials to withstand the pressures and temperatures of commercial truck operations. The valve incorporates a precision-machined element that ensures a tight seal when closed, preventing any reverse flow. Additionally, the valve is engineered for easy installation and maintenance, with features that allow for straightforward replacement or repair if needed.

Benefits

The advantages provided by the Cummins 3027507 Check Valve include improved system efficiency and reliability. By preventing backflow, the valve helps maintain the intended pressure and flow within the system, which can lead to better overall performance of the truck. Its robust construction and precise engineering contribute to its longevity, reducing the need for frequent replacements and lowering maintenance costs over time 3.

Installation Considerations

For the proper installation of the Cummins 3027507 Check Valve, it is important to follow guidelines that ensure correct orientation and system compatibility. The valve should be installed in the direction of flow, with attention paid to the system’s specific requirements for pressure and temperature. Ensuring that the valve is securely fastened and that all connections are tight will help prevent leaks and ensure optimal performance.

Maintenance and Troubleshooting

Maintaining the Cummins 3027507 Check Valve involves regular inspection for signs of wear or damage. Common issues that may arise include a failure to seal properly, which can be indicated by leaks or a drop in system efficiency. Troubleshooting tips include checking the valve’s orientation, ensuring that it is not obstructed, and verifying that all connections are secure. If the valve is found to be faulty, replacement is typically the recommended course of action.

Performance in Various Conditions

The Cummins 3027507 Check Valve is designed to perform under a range of operating conditions, including extreme temperatures and high-pressure environments. Its materials and construction are chosen to withstand these challenges, ensuring that the valve continues to function effectively regardless of the conditions it encounters. This reliability is crucial for the consistent performance of commercial trucks in diverse operational scenarios.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established itself as a key player in the commercial truck industry, providing innovative solutions that enhance the performance, efficiency, and reliability of vehicles. The company’s commitment to quality and customer satisfaction is reflected in its wide range of products, including the Cummins 3027507 Check Valve.

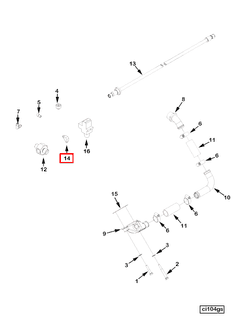

Compatibility of Cummins Check Valve Part 3027507

The Cummins Check Valve part number 3027507 is designed to ensure unidirectional flow in various engine systems, preventing backflow and maintaining system integrity. This check valve is compatible with several Cummins engine models, enhancing their operational efficiency and reliability.

K-Series Engines

The K19, K38, and K50 engines are part of Cummins’ K-Series line, known for their robust design and performance in heavy-duty applications. The check valve part 3027507 fits seamlessly into these engines, providing essential flow control and protection against backflow, which is crucial for maintaining optimal engine performance.

L10 MECHANICAL Engine

The L10 MECHANICAL engine, another robust Cummins model, benefits from the check valve part 3027507. This engine, often used in demanding industrial and marine applications, relies on the check valve to ensure that fluid flows in the correct direction, thereby preventing potential damage and ensuring smooth operation.

NH/NT 855 Engines

The NH/NT 855 engines, part of Cummins’ agricultural and construction equipment lineup, also integrate the check valve part 3027507. This ensures that the hydraulic systems within these engines operate efficiently, with the check valve playing a critical role in maintaining the correct flow direction and preventing backflow.

V-Series Engines

The V28 and V903 engines, both part of Cummins’ V-Series, are designed for high-performance applications. The check valve part 3027507 is a crucial component in these engines, ensuring that the hydraulic systems function correctly and efficiently. Its role in preventing backflow is vital for maintaining the integrity and performance of these powerful engines.

Role of Part 3027507 Check Valve in Engine Systems

In the context of engine systems, the Part 3027507 Check Valve is instrumental in maintaining the integrity and efficiency of fuel delivery. It is integrated into various fuel pump configurations, ensuring that fuel flow is unidirectional and preventing backflow, which could lead to inefficiencies or damage within the system.

Integration with Fuel Pumps

-

AFC Auto Fuel Pump and AFC VS Fuel Pump: The Check Valve works in conjunction with these fuel pumps to ensure that fuel is delivered consistently to the engine without any reverse flow, which could disrupt the fuel pressure and affect engine performance.

-

Auto Fuel Pump & Drive and Gear Fuel Pump: When installed with these pumps, the Check Valve helps in maintaining a stable fuel supply by preventing any fuel from flowing back into the tank, thus ensuring that the pump operates under optimal conditions.

Role in Calibration and Repair

-

Fuel Pump @ Cal. and Fuel Pump AFC: During calibration processes, the Check Valve ensures that the fuel system maintains the desired pressure levels, which is essential for accurate calibration readings and adjustments.

-

Fuel Pump Repair Kit and Fuel Pump Sub-Option: In repair scenarios, the Check Valve is often replaced or inspected to ensure that the repaired fuel pump system functions correctly without any issues related to fuel backflow.

Application in Various Fuel Systems

-

Non AFC-Auto/TMD and Non AFC-VS/TMD: These systems benefit from the Check Valve by ensuring that the fuel delivery remains efficient and consistent, which is particularly important in systems where fuel pressure needs to be tightly controlled.

-

Non-AFC Auto FP/WW Sump: In this configuration, the Check Valve plays a key role in preventing fuel from draining back into the sump, which could otherwise lead to inconsistent fuel levels and pressure.

Supporting Components

-

Fuel Tubing and Pump: The Check Valve is often placed within the fuel tubing to intercept any reverse flow, ensuring that the pump delivers fuel efficiently to the engine.

-

HSG, Master Cam Foll., and Master Cam Follow Housing: Although these components are more related to the mechanical aspects of the engine, the Check Valve ensures that the fuel system supporting these components operates without interruptions or inefficiencies.

Miscellaneous Applications

-

Lloyds Spares and Engine Spares: When dealing with spare parts, the Check Valve is a common component that ensures the replacement or upgraded fuel systems function as intended.

-

Uncalibrated VS and Pump: Even in systems that are not yet calibrated, the Check Valve provides a baseline level of protection against fuel backflow, ensuring that the system is ready for calibration once all components are in place.

The Part 3027507 Check Valve, therefore, is a fundamental component in various engine fuel systems, ensuring that fuel delivery is efficient, consistent, and free from backflow issues.

Conclusion

The Cummins 3027507 Check Valve is a vital component in commercial truck systems, ensuring unidirectional fluid flow and preventing backflow. Its robust design, ease of maintenance, and compatibility with various Cummins engine models make it an essential part for maintaining system efficiency and reliability. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩ -

Hu, H., Baseley, S.J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.