This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

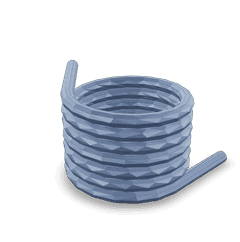

The Cummins 3024169 Torsion Spring is a component designed for use in commercial trucks. Its purpose is to provide a specific mechanical function that contributes to the overall operation and efficiency of the vehicle. Understanding its role and significance can help in maintaining and optimizing truck performance.

Basic Concepts of Torsion Springs

Torsion springs are mechanical devices that store and release rotational force. They operate by twisting along their axis when a force is applied, and they return to their original shape when the force is removed. These springs are commonly used in various mechanical systems to provide torque, maintain tension, or store energy. Their applications range from simple mechanisms like door hinges to complex machinery in industrial settings 1.

Purpose of the 3024169 Torsion Spring in Truck Operation

The 3024169 Torsion Spring plays a role in the mechanical system of commercial trucks by providing necessary tension and rotational force. It is involved in components that require consistent and reliable torque, such as in the suspension system or other moving parts where precise control of motion is required. Its function ensures that these parts operate smoothly and efficiently, contributing to the truck’s overall performance 2.

Key Features

The 3024169 Torsion Spring is characterized by several key features that enhance its performance. It is made from high-quality materials that offer durability and resistance to wear. The design specifications include precise dimensions and a robust construction that ensures it can withstand the stresses of commercial truck operations. Additionally, it may have unique attributes such as a specific coil diameter or wire gauge that are optimized for its intended application 3.

Benefits of Using the 3024169 Torsion Spring

Using the 3024169 Torsion Spring offers several advantages in truck operations. It contributes to improved efficiency by ensuring that mechanical components function with minimal friction and maximum reliability. Its durable construction means it can withstand the rigors of heavy-duty use, providing long-term performance. Additionally, the spring’s reliable operation helps in maintaining consistent truck performance, reducing the likelihood of unexpected failures 4.

Installation Process

Installing the 3024169 Torsion Spring requires careful attention to detail. The process involves securing the spring in its designated position within the truck’s mechanical system. Tools such as spring compressors and wrenches may be necessary. Safety precautions, including wearing protective gear and ensuring the truck is securely supported, should be observed during installation to prevent accidents and ensure proper fitting 5.

Troubleshooting Common Issues

Common problems with the 3024169 Torsion Spring may include issues such as reduced tension or failure to return to the original shape. These problems can be caused by wear and tear, improper installation, or exposure to extreme conditions. Solutions may involve inspecting the spring for damage, ensuring it is correctly installed, or replacing it if necessary. Regular checks can help identify and address these issues before they lead to more significant problems 6.

Maintenance Tips

To ensure the longevity and optimal performance of the 3024169 Torsion Spring, regular maintenance is recommended. This includes inspecting the spring for signs of wear or damage, ensuring it remains properly tensioned, and cleaning it to remove any debris that may affect its operation. Following these maintenance routines can help prevent issues and ensure the spring continues to function effectively 7.

Cummins Corporation Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products including engines, filtration systems, and components like the 3024169 Torsion Spring. With a history of innovation and quality, Cummins has built a reputation for providing reliable and high-performance parts that contribute to the efficiency and durability of commercial vehicles.

Torsion Spring Part 3024169 Compatibility with Cummins Engines

The Torsion Spring part number 3024169, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This part is engineered to provide reliable performance and durability, ensuring the smooth operation of the engines it is paired with.

K Series Engines

- K19

- K38

- K50

The Torsion Spring part 3024169 is compatible with the K19, K38, and K50 engines, providing essential support and functionality in these models. Its design ensures that it can handle the specific demands of these engines, contributing to their overall efficiency and longevity.

L Series Engines

- L10 MECHANICAL

The L10 MECHANICAL engine benefits from the precise engineering of the Torsion Spring part 3024169. This part is tailored to meet the unique requirements of the L10 MECHANICAL engine, ensuring optimal performance and reliability.

M Series Engines

- M11 CELECT PLUS

- M11 MECHANICAL

Both the M11 CELECT PLUS and M11 MECHANICAL engines are designed to work effectively with the Torsion Spring part 3024169. This compatibility ensures that these engines can operate smoothly, with the torsion spring providing the necessary support and functionality.

N Series Engines

- N14 MECHANICAL

The N14 MECHANICAL engine is another model that is compatible with the Torsion Spring part 3024169. This part is engineered to fit this engine perfectly, ensuring that it can perform at its best under various operating conditions.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine is also compatible with the Torsion Spring part 3024169. This compatibility ensures that the engine can operate efficiently, with the torsion spring providing the necessary support and functionality.

V Series Engines

- V28

- V903

The V28 and V903 engines are designed to work with the Torsion Spring part 3024169. This part is engineered to fit these engines perfectly, ensuring that they can perform at their best under various operating conditions.

Role of Part 3024169 Torsion Spring in Engine Systems

The part 3024169 torsion spring is integral to the operation of various components within engine systems. Its primary function is to provide the necessary tension and return force for components that require precise and consistent movement.

Lever and Throttle Mechanisms

In lever and throttle systems, the torsion spring ensures that the lever returns to its default position after being actuated. This is essential for maintaining the correct throttle setting and ensuring that the engine operates within safe parameters. The spring’s design allows for smooth and reliable operation, minimizing the risk of mechanical failure.

Engine Mounting Parts Kit

Within the engine mounting parts kit, the torsion spring helps in stabilizing components that experience vibrational forces. By providing consistent tension, it aids in reducing wear and tear on mounting brackets and other structural elements, thereby enhancing the longevity of the engine mounting system.

Fuel Sub 24V Pump

For the fuel sub 24V pump, the torsion spring is used in the solenoid and mounting valve mechanisms. It ensures that the valve returns to its closed position after fuel delivery, preventing fuel leakage and maintaining the integrity of the fuel system. This consistent action is vital for the pump’s efficient operation.

Throttle Linkage & Governor

In the throttle linkage and governor system, the torsion spring plays a key role in maintaining the balance between the throttle position and the engine’s RPM. It provides the necessary resistance to govern the throttle’s movement, ensuring that the engine operates smoothly under varying load conditions.

Vernier Throttle Control

The vernier throttle control benefits from the torsion spring by offering fine adjustments in throttle position. The spring’s tension allows for precise control, which is essential for applications requiring exact throttle settings, such as in VT903 short block kits where engine performance is finely tuned.

Solenoid and Mounting Valve

In solenoid and mounting valve applications, the torsion spring ensures that the valve returns to its default state after being energized. This is important for maintaining the valve’s operational integrity and ensuring that the engine system functions correctly.

Throttle Lever

The throttle lever utilizes the torsion spring to provide a return force that brings the lever back to its resting position. This ensures that the throttle does not remain in an open position, which could lead to unintended high engine speeds.

By understanding the role of the part 3024169 torsion spring in these components, engineers and mechanics can better appreciate its importance in maintaining the overall functionality and reliability of engine systems.

Conclusion

The Cummins 3024169 Torsion Spring is a critical component in the operation of commercial trucks and various Cummins engines. Its role in providing necessary tension and rotational force ensures the smooth and efficient operation of mechanical systems. Understanding its features, benefits, and proper maintenance can help in optimizing truck and engine performance, ultimately contributing to the longevity and reliability of these vehicles.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook (2nd ed.). Gulf Professional Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613010.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613010.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613010.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.