This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

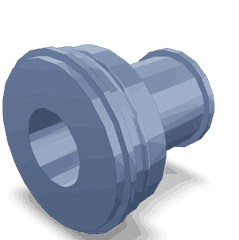

The Cummins 3021895 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine to the truck’s frame and other components. Its role is vital in ensuring the smooth operation of commercial trucks, contributing to both the longevity of the vehicle and the comfort of its occupants 1.

Basic Concepts of Vibration Isolators

Vibration isolators are devices that reduce the transmission of vibrations between two surfaces. They function by absorbing and dissipating vibrational energy, thereby minimizing the impact of vibrations on connected components. In mechanical systems, particularly heavy-duty trucks, vibration isolators play a significant role in maintaining the integrity and efficiency of the vehicle. They help in reducing wear and tear on components, enhancing ride comfort, and ensuring the stable operation of sensitive equipment 2.

Purpose of the Cummins 3021895 Vibration Isolator

This Cummins part is specifically designed to reduce vibrations transmitted from the engine to the truck’s frame and other components. By doing so, it helps in maintaining the structural integrity of the truck, enhancing the comfort of the ride, and ensuring the efficient operation of the engine and its ancillary systems.

Key Features

The 3021895 features a robust design that incorporates high-quality materials to ensure durability and effectiveness. Its construction includes elastomeric components that provide excellent vibration damping capabilities. Additionally, the isolator is engineered to withstand the harsh conditions typical of commercial truck operations, ensuring reliable performance over time.

Benefits

Utilizing this part offers several advantages. It contributes to improved ride comfort by reducing the vibrations felt by the truck’s occupants. Furthermore, it helps in reducing wear and tear on truck components, leading to lower maintenance costs and extended component lifespan. Enhanced engine performance is also a benefit, as the isolator helps in maintaining optimal engine operation conditions.

Installation Process

Installing the 3021895 involves several steps to ensure proper fitting and function. The process requires specific tools and equipment, and it is important to follow manufacturer guidelines to achieve the best results. Key considerations include ensuring the isolator is correctly aligned and securely fastened to prevent any movement that could compromise its effectiveness.

Troubleshooting Common Issues

Common issues with this Cummins part may include excessive vibration or noise. Troubleshooting these problems involves checking the isolator for signs of wear or damage, ensuring it is properly installed, and verifying that all connections are secure. Addressing these issues promptly can help in maintaining the isolator’s performance and the overall efficiency of the truck.

Maintenance Tips

Regular maintenance of the 3021895 is crucial for ensuring its optimal performance and longevity. This includes periodic inspections for signs of wear or damage, cleaning the isolator to remove any debris that could affect its function, and replacing it when necessary. Adhering to these maintenance practices helps in preventing unexpected failures and ensuring the isolator continues to effectively reduce vibrations.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is committed to quality and innovation in engine and component manufacturing. The company’s extensive range of products and services is designed to meet the diverse needs of its customers, ensuring reliable and efficient performance across various applications.

Cummins Vibration Isolator 3021895 Compatibility

The Cummins Vibration Isolator part number 3021895 is designed to be compatible with a range of Cummins engines, ensuring effective noise and vibration reduction across various applications. This part is engineered to fit seamlessly with the following engines:

- K19

- K38

- K50

Additionally, the 3021895 Vibration Isolator is also compatible with the following engines:

- NH/NT 855

- V28

These engines, while differing in their specific applications and configurations, share a commonality in their need for effective vibration management. The 3021895 Vibration Isolator is crafted to address these needs, providing a reliable solution for reducing operational noise and mitigating the effects of vibration. This compatibility ensures that users can maintain optimal performance and longevity of their engines by integrating this essential component.

Role of Part 3021895 Vibration Isolator in Engine Systems

The Part 3021895 Vibration Isolator is integral to the efficient and reliable operation of various engine systems by mitigating the transmission of vibrations. When integrated with the Instrument Panel, the Vibration Isolator ensures that the panel remains stable and free from unwanted vibrations, which can otherwise lead to discomfort for the operator and potential damage to sensitive instrumentation.

In conjunction with the Instrument Panel Enclosure, the Vibration Isolator helps maintain the structural integrity of the enclosure. This is particularly important as the enclosure often houses delicate electronic components that are sensitive to vibrations. By reducing the vibrational energy transmitted to the enclosure, the isolator enhances the longevity and reliability of these components.

The Mounting (MTG.) systems benefit significantly from the incorporation of the Vibration Isolator. Whether it is the mounting of the engine itself or ancillary components, the isolator ensures that the mounting points experience reduced stress and wear. This not only prolongs the lifespan of the mounting hardware but also contributes to the overall stability of the engine system.

Lastly, when paired with Brackets, the Vibration Isolator plays a key role in maintaining the alignment and stability of various engine components. Brackets often support pipes, wires, and other critical elements, and any undue vibration can lead to misalignment or even failure. The isolator helps in dampening these vibrations, thereby ensuring that the brackets perform their function effectively over an extended period.

Conclusion

The Cummins 3021895 Vibration Isolator is a critical component in the operation of commercial trucks, offering significant benefits in terms of ride comfort, component longevity, and engine performance. Its robust design and compatibility with various Cummins engines make it a reliable choice for vibration management in heavy-duty applications. Regular maintenance and proper installation are key to ensuring the optimal performance of this part, contributing to the overall efficiency and reliability of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.