This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

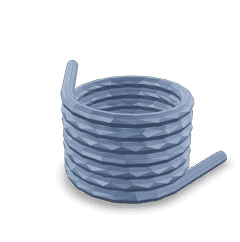

The Cummins 3019416 Torsion Spring is a vital component in commercial trucks, contributing to the vehicle’s operational efficiency. This spring ensures smooth and reliable performance in various systems, highlighting its importance in maintaining the truck’s overall health and efficiency.

Basic Concepts of Torsion Springs

Torsion springs store and release rotational energy by twisting along their axis when a force is applied. These springs are used in various mechanical systems to provide torque, maintain tension, or return components to their original position. Their applications range from household items to complex industrial machinery .

Purpose of the 3019416 Torsion Spring

This part plays a role in the truck’s operation by providing necessary tension and rotational force in specific systems. It ensures components function correctly under various operational conditions, maintaining the integrity and performance of the truck’s mechanical components .

Key Features

The 3019416 Torsion Spring is constructed from high-quality materials, ensuring durability and reliability under demanding conditions. Its design specifications include precise dimensions and a robust build to withstand the stresses encountered in commercial truck applications. Unique attributes such as corrosion resistance and fatigue strength enhance its performance and longevity .

Benefits

The use of the 3019416 Torsion Spring offers several advantages. It contributes to improved reliability by ensuring consistent performance of the associated systems. Enhanced performance is achieved through its precise engineering, which maintains optimal tension and rotational force. Additionally, its durability can lead to potential cost savings for fleet operators by reducing the frequency of replacements and maintenance interventions .

Installation Process

Installing this Cummins part requires careful attention to detail. The process involves securing the spring in its designated position within the truck’s system, ensuring it is correctly aligned and tensioned. Tools and equipment necessary for installation may include wrenches, torque wrenches, and alignment tools. Safety precautions, such as wearing protective gear and ensuring the truck is securely supported, should be observed throughout the installation process .

Troubleshooting Common Issues

Common problems associated with the 3019416 Torsion Spring may include wear and tear, fatigue, or malfunction due to improper installation or environmental factors. Troubleshooting steps involve inspecting the spring for signs of damage, ensuring it is correctly installed, and replacing it if necessary. Regular maintenance and inspections can help identify issues early, preventing more significant problems down the line .

Maintenance Tips

To ensure the optimal performance and longevity of the 3019416 Torsion Spring, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage, cleaning the spring and its surrounding components to prevent corrosion, and following manufacturer guidelines for replacement intervals. Adhering to these maintenance practices can help maintain the spring’s efficiency and reliability .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and commitment to customer satisfaction. The development and manufacturing of the 3019416 Torsion Spring reflect Cummins’ dedication to providing reliable and efficient components for the commercial truck market .

Role of Part 3019416 Torsion Spring in Engine Systems

This part is integral to the efficient operation of several engine components. Its primary function is to provide the necessary tension and stability required for the smooth functioning of these parts.

Belt Tensioner

The torsion spring within the belt tensioner system ensures that the correct amount of tension is maintained on the drive belt. This is essential for the proper transfer of power from the engine to various components such as the alternator, water pump, and air conditioning compressor.

Drive and Fan Systems

In the drive and fan systems, the torsion spring helps in maintaining the optimal distance between the fan and the radiator. This ensures efficient airflow for cooling the engine, preventing overheating, and maintaining engine performance.

Fan Drive Arrangement

Within the fan drive arrangement, the torsion spring assists in the smooth operation of the fan clutch. It allows the fan to engage and disengage as needed, based on the engine’s cooling requirements, thereby optimizing engine efficiency and reducing unnecessary strain on the engine.

Fan Idler and Idler Assembly

The torsion spring is also a key component in the fan idler and idler assembly. It provides the necessary tension to keep the idler pulley in constant contact with the drive belt, ensuring consistent belt tension and reducing the risk of belt slippage or failure.

Idler Pulley and Idler Pulley Assembly

In the idler pulley and idler pulley assembly, the torsion spring ensures that the pulley maintains the correct tension on the belt. This is vital for the proper functioning of the pulley, which helps in changing the direction of the belt and maintaining its alignment.

Idler Lever and Idler Pulley Kit

The torsion spring in the idler lever and idler pulley kit plays a role in adjusting the tension of the belt. It allows for fine-tuning of the belt tension, which is crucial for the longevity and performance of the belt and the components it drives.

Mounting and Spare Mounting

In mounting systems, particularly those involving fan drives and radiator cooling components, the torsion spring ensures that these parts are securely held in place. This is important for the structural integrity of the engine system and for the efficient operation of cooling components.

Overall, the 3019416 torsion spring is a versatile component that enhances the reliability and performance of various engine systems by providing essential tension and stability.

Conclusion

The 3019416 Torsion Spring by Cummins is a critical component in commercial trucks, ensuring the efficient operation of various engine systems. Its role in maintaining tension and stability across different components highlights its importance in the overall performance and reliability of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the longevity and efficiency of the truck’s engine systems.

## References

: Bonneau, D., Fatu, A., & Souchet, D. (2014). *Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings*. Wiley-ISTE.

: Bennett, S. (2012). *Modern Diesel Technology Light Duty Diesels*. Cengage Learning.

: Sully, F. K. (1998). *Motor Vehicle Mechanics Textbook, Fifth Edition*. Heinemann Professional Publishing.

: Cummins Inc. (n.d.). *Service Manual (4383781)*. QSK60 G CM2358 K110.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.