This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3019415 Torsion Spring is a critical component in commercial trucks, enhancing operational efficiency. This spring is essential for the smooth and reliable performance of the truck’s mechanical systems. Understanding its function and significance can improve the maintenance and operation of commercial trucks.

Basic Concepts of Torsion Springs

Torsion springs are mechanical devices that store and release rotational force. They operate by twisting along their axis when torque is applied, storing potential energy that can be released to perform work. These springs are commonly used in various mechanical systems to provide rotational force, maintain tension, or return components to their original position after movement 1.

Role of the 3019415 Torsion Spring in Truck Operation

The 3019415 Torsion Spring plays a specific role in the operation of commercial trucks by providing the necessary rotational force for certain mechanical functions. It interacts with other components to ensure that systems operate smoothly and efficiently. This spring is typically involved in mechanisms that require precise control of rotational movement, contributing to the overall performance and reliability of the truck 2.

Key Features

The 3019415 Torsion Spring is designed with specific features to enhance its functionality and durability. It is composed of high-quality materials that provide strength and resilience. The design specifications of this spring ensure it can withstand the stresses and strains of commercial truck operations. Unique attributes may include a specific coil diameter, wire gauge, and treatment processes that enhance its performance 3.

Benefits of Using the 3019415 Torsion Spring

Using the 3019415 Torsion Spring offers several advantages. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The spring’s reliable operation contributes to the overall efficiency of the truck’s mechanical systems. Additionally, its precise design enhances the performance of the components it interacts with, leading to smoother and more consistent truck operation 4.

Installation Process

Proper installation of the 3019415 Torsion Spring is crucial for ensuring its effective function. The process involves several steps:

- Ensure the truck is safely supported and the engine is off.

- Locate the component where the spring will be installed.

- Use appropriate tools to remove the old spring, if applicable.

- Position the new 3019415 Torsion Spring according to the manufacturer’s specifications.

- Secure the spring in place, ensuring it is correctly aligned with other components.

- Test the installation by operating the relevant system to confirm proper function.

Maintenance Tips

To ensure the longevity and optimal performance of the 3019415 Torsion Spring, regular maintenance is recommended. This includes:

- Inspecting the spring for signs of wear or damage at regular intervals.

- Cleaning the spring and its surrounding components to prevent buildup of dirt or debris.

- Lubricating the spring as necessary to reduce friction and wear.

- Following the manufacturer’s guidelines for maintenance and care.

Troubleshooting Common Issues

Common problems associated with the 3019415 Torsion Spring may include reduced performance, unusual noises, or visible signs of wear. To address these issues:

- Inspect the spring for physical damage or deformation.

- Check for proper alignment and secure fitting within the system.

- Ensure there is no obstruction or interference with other components.

- Replace the spring if it shows significant wear or failure.

Compatibility and Applications

The 3019415 Torsion Spring is designed for use in specific types of trucks and models. It is commonly applied in commercial trucks where precise rotational force is required for mechanical operations. Compatibility ensures that the spring functions correctly within the truck’s system, contributing to efficient and reliable performance.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. The company has a long history of innovation and excellence, offering a wide range of products designed to enhance the performance and reliability of commercial vehicles. Cummins’ reputation is built on its commitment to quality, durability, and customer satisfaction.

Cummins Engine Compatibility with Torsion Spring Part 3019415

The Torsion Spring part 3019415, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This part is essential for maintaining the operational integrity of the engine’s components, ensuring smooth and reliable performance.

K19 and K38 Engines

The K19 and K38 engines benefit from the precise tension control provided by the Torsion Spring part 3019415. This part is crucial in managing the movement of specific engine components, enhancing the overall efficiency and durability of these engines.

KTA19GC and KTA19GC CM558 Engines

For the KTA19GC and KTA19GC CM558 engines, the Torsion Spring part 3019415 plays a pivotal role in maintaining the alignment and tension of various parts. This ensures that the engines operate smoothly, reducing wear and tear and extending the service life of the engine.

QSK19 CM500 and QST30 CM552 Engines

In the QSK19 CM500 and QST30 CM552 engines, the Torsion Spring part 3019415 is integral to the engine’s performance. It provides the necessary tension to keep components in their correct positions, which is vital for the engines’ optimal functioning. This part’s precision engineering ensures that these engines maintain their high standards of performance and reliability.

Role of Part 3019415 Torsion Spring in Engine Systems

The part 3019415 torsion spring is integral to the efficient operation of various engine components. Its primary function is to provide the necessary tension and control in the movement of mechanical parts, ensuring smooth and reliable performance.

Drive and Fan Systems

In drive and fan systems, the torsion spring plays a significant role in maintaining the correct tension between the drive components and the fan. This ensures that the fan operates at the optimal speed and angle, which is essential for effective engine cooling and overall performance. The spring helps in absorbing shocks and vibrations, thereby prolonging the lifespan of the drive and fan components.

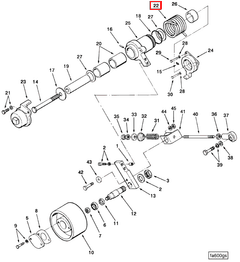

Fan Drive and Idler Assemblies

The torsion spring is also vital in the fan drive arrangement and the fan idler assembly. It assists in the smooth transfer of motion from the engine to the fan, ensuring that the fan blades are driven consistently without undue stress on the system. In the idler assembly, the spring helps maintain the proper alignment and tension of the fan belt, which is crucial for the efficient operation of the cooling system.

Follower and Cam Mechanisms

In follower and cam mechanisms, the torsion spring ensures that the follower maintains consistent contact with the cam. This is important for the precise timing and operation of various engine functions. The spring’s ability to store and release energy helps in maintaining the smooth operation of these components, reducing wear and tear.

Pivot Arm Assembly

Within the pivot arm assembly, the torsion spring provides the necessary force to keep the arm in the correct position. This is particularly important in systems where the pivot arm needs to move through a specific range of motion, such as in certain types of fan arrangements or idler lever setups. The spring ensures that the arm returns to its neutral position after movement, maintaining the integrity of the system.

Idler Lever and Fan Assembly Idler

The idler lever and the fan assembly idler both benefit from the torsion spring’s properties. In the idler lever, the spring helps in maintaining tension and ensuring that the lever operates within its designed parameters. For the fan assembly idler, the spring assists in keeping the idler in the correct position, which is essential for the smooth operation of the fan assembly.

Conclusion

Overall, the part 3019415 torsion spring is a key component in various engine systems, providing the necessary tension, control, and stability to ensure the efficient and reliable operation of mechanical parts.

-

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.