This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

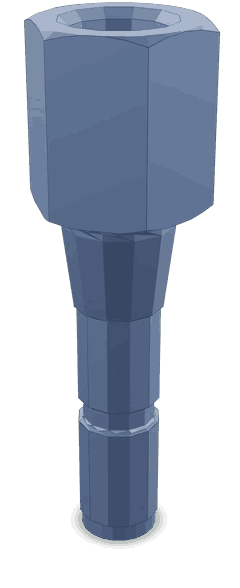

The Cummins 3015522 Check Valve is a component designed for use in commercial trucks. Its purpose is to regulate the flow of fluids within the truck’s systems, ensuring that fluid moves in the intended direction and preventing backflow. This valve is significant in maintaining the efficiency and reliability of the truck’s fluid systems, contributing to overall performance and longevity.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a device that allows fluid to flow through it in one direction only. It operates by using a mechanism, such as a spring-loaded plunger or a swing gate, that opens when fluid flows in the correct direction and closes to prevent backflow when the flow reverses. Check valves are commonly used in various fluid systems, including hydraulic, pneumatic, and fuel systems, to maintain system integrity and prevent damage from reverse flow 1.

Purpose of the 3015522 Check Valve

This Cummins part plays a role in the operation of a truck by ensuring that fluid flows in the correct direction within the truck’s fluid systems. This valve is typically installed in systems where backflow could cause issues, such as in fuel lines to prevent fuel from returning to the tank or in hydraulic systems to maintain pressure. By regulating fluid flow, the 3015522 Check Valve helps to maintain system efficiency and protect other components from damage due to reverse flow 2.

Key Features

The Cummins 3015522 Check Valve is designed with several key features that enhance its performance. It is constructed from durable materials to withstand the pressures and temperatures encountered in commercial truck applications. The valve’s design includes a precise sealing mechanism that ensures effective prevention of backflow. Additionally, it is engineered to be compatible with a range of system components, facilitating easy integration into existing truck fluid systems.

Benefits

This Cummins part offers several benefits to truck operators. By ensuring unidirectional fluid flow, it contributes to improved system efficiency and reliability. This valve helps to maintain consistent system performance, reducing the likelihood of issues related to backflow. Furthermore, by protecting system components from damage, it can lead to cost savings in maintenance and repairs over time 3.

Installation Considerations

Proper installation of the 3015522 Check Valve is important for its effective operation. It should be installed in the correct orientation, with the flow arrow indicating the direction of fluid flow. Attention to fitting requirements and ensuring compatibility with other system components is necessary to avoid issues. Following manufacturer guidelines for installation will help to ensure the valve functions as intended within the truck’s fluid systems.

Troubleshooting and Maintenance

Common issues with the 3015522 Check Valve may include failure to seal properly, leading to backflow, or obstructions within the valve that impede fluid flow. Regular inspection and maintenance, such as cleaning the valve and checking for wear or damage, can help to prevent these issues. Diagnostic tips include observing system performance for signs of backflow or reduced efficiency, which may indicate a problem with the check valve.

Performance in Various Conditions

The 3015522 Check Valve is designed to perform reliably under a range of operating conditions. It can withstand temperature variations and pressure fluctuations commonly encountered in commercial truck applications. The valve is also built to resist the effects of contaminants that may be present in the fluid systems, ensuring consistent performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses, demonstrating its commitment to providing reliable and efficient power solutions.

Compatibility with Various Engines

The Cummins Check Valve 3015522 is designed to ensure the unidirectional flow of fluids within the engine system. This valve is engineered to prevent backflow, which can cause significant damage to the engine components. Below is a detailed description of how this check valve fits with various Cummins engines.

K-Series Engines

- K19: The K19 engine benefits from the check valve’s ability to maintain fluid pressure and prevent backflow, ensuring optimal performance and longevity.

- K38: Similar to the K19, the K38 engine relies on the check valve to maintain system integrity and prevent fluid from flowing in the wrong direction.

- K50: The K50 engine also utilizes the check valve to ensure that fluids flow in the correct direction, enhancing the engine’s efficiency and reliability.

L-Series Engines

- L10 MECHANICAL: The L10 MECHANICAL engine incorporates the check valve to maintain fluid pressure and prevent backflow, ensuring smooth operation and reducing the risk of damage.

M-Series Engines

- M11 CELECT PLUS: The M11 CELECT PLUS engine uses the check valve to maintain fluid pressure and prevent backflow, contributing to the engine’s overall efficiency and reliability.

- M11 MECHANICAL: The M11 MECHANICAL engine also benefits from the check valve, ensuring that fluids flow in the correct direction and preventing backflow that could cause damage.

N-Series Engines

- N14 MECHANICAL: The N14 MECHANICAL engine relies on the check valve to maintain fluid pressure and prevent backflow, ensuring optimal performance and longevity.

NH/NT Series Engines

- NH/NT 855: The NH/NT 855 engine incorporates the check valve to maintain fluid pressure and prevent backflow, enhancing the engine’s efficiency and reliability.

V-Series Engines

- V28: The V28 engine uses the check valve to maintain fluid pressure and prevent backflow, ensuring smooth operation and reducing the risk of damage.

- V903: The V903 engine also benefits from the check valve, ensuring that fluids flow in the correct direction and preventing backflow that could cause damage.

The Cummins Check Valve 3015522 is a versatile component that is compatible with a wide range of Cummins engines, ensuring that each engine operates efficiently and reliably by preventing backflow and maintaining fluid pressure.

Role in Engine Systems

The 3015522 Check Valve is integral to the efficient operation of various engine systems, particularly in ensuring the unidirectional flow of fluids. Here’s how it interfaces with the provided components:

Fuel Systems

- Fuel Pump (FP) and Fuel Pump AFC: The check valve prevents backflow in the fuel lines, ensuring that fuel delivered by the fuel pump and fuel pump AFC reaches the engine without any reverse flow, which could cause inefficiencies or damage.

- Fuel Pump and Drive, Fuel Pump Hardware, Fuel Pump Option: These components rely on consistent fuel flow. The check valve maintains pressure and prevents fuel from flowing back into the system, ensuring optimal performance of the fuel pump and its associated hardware.

- Fuel Tubing and Fuel Lines: Installed in fuel lines, the check valve ensures that fuel moves toward the engine, preventing any reverse flow that could lead to fuel starvation or inconsistent fuel delivery.

Aftercooler Systems

- Aftercooler - Auto / Multi - Unit and Aftercooler - Variable Speed: These systems benefit from the check valve by maintaining consistent coolant flow. It prevents coolant from flowing back, ensuring efficient heat exchange and optimal engine cooling.

- Aftercooler Cover Assembly and Aftercooler Flow Valve Field Kit: The check valve helps in maintaining the integrity of the coolant flow within these assemblies, preventing any reverse flow that could disrupt the cooling process.

- Aftercooler Variable Speed Hydraulic Assembly: In this assembly, the check valve ensures that hydraulic fluid flows in the correct direction, maintaining the efficiency and reliability of the variable speed functionality.

Calibration and Plumbing

- Calibration: Accurate calibration of fuel and coolant systems depends on consistent fluid flow. The check valve plays a role in maintaining this consistency by preventing any reverse flow that could affect calibration settings.

- Plumbing - Fuel Pump: In the plumbing of fuel systems, the check valve is essential for maintaining pressure and ensuring that fuel flows in the intended direction, which is vital for the accurate functioning of the fuel pump.

Manifold and Mounting

- Mounting and Manifold Tube (MTG.) and Manifold Pressure Tube: These components are part of the engine’s air intake system. The check valve, when used in associated fluid lines, helps in maintaining consistent pressure and flow, which is crucial for the manifold’s efficient operation.

Coupling and Fuel Injection

- Coupling - Fuel Pump and Pump - Fuel Injection: In these applications, the check valve ensures that fuel is delivered to the injection system without any backflow, which is essential for precise fuel injection and engine performance.

Conclusion

In summary, the 3015522 Check Valve is a key component in various engine systems, ensuring unidirectional fluid flow, maintaining system pressure, and contributing to the overall efficiency and reliability of the engine.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.