This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3014232 Eye Bolt is a specialized fastener designed for use in commercial trucks. Its primary function is to provide a secure attachment point for various towing, lifting, and load-securing applications. This component is integral to ensuring the safe and efficient operation of heavy-duty trucks in diverse commercial settings.

Basic Concepts of Eye Bolts

An eye bolt is a type of fastener characterized by a looped head, which allows for the attachment of ropes, cables, or other securing devices. Eye bolts are commonly used across various industries for applications requiring secure anchoring points. Mechanically, the eye bolt functions by distributing the load evenly across the threaded shaft and the looped head, providing a stable and reliable connection 1.

Purpose of the Cummins 3014232 Eye Bolt

The Cummins 3014232 Eye Bolt plays a significant role in the operation of commercial trucks by facilitating the secure attachment of towing equipment, lifting gear, and load-securing straps. Its applications include towing heavy loads, lifting equipment during maintenance procedures, and securing cargo to prevent shifting during transit. The eye bolt ensures that these operations are performed safely and efficiently.

Key Features

The Cummins 3014232 Eye Bolt is designed with several key features that enhance its performance and reliability. It is constructed from high-strength materials, typically steel, to withstand substantial loads. The thread type is designed to provide a secure fit, preventing loosening under vibration or dynamic loads. Additionally, the eye bolt is rated for specific load-bearing capacities, ensuring it can handle the intended applications without failure 2.

Benefits

Using the Cummins 3014232 Eye Bolt offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The design allows for easy installation, minimizing downtime during truck maintenance. Furthermore, its robust build contributes to the overall safety and efficiency of commercial truck operations.

Installation Guidelines

Proper installation of the Cummins 3014232 Eye Bolt is crucial for its effective performance. Begin by selecting the appropriate location on the truck frame or chassis. Use a torque wrench to install the eye bolt to the specified torque settings, typically provided in the manufacturer’s guidelines. Ensure that the eye bolt is perpendicular to the surface to which it is attached, and verify that there is no excessive play or movement once installed.

Troubleshooting Common Issues

Common issues associated with eye bolts include corrosion, stripping of the threads, and fatigue. Corrosion can be mitigated by applying a protective coating or using stainless steel variants. Stripping can be prevented by using the correct torque settings during installation and avoiding over-tightening. Fatigue, resulting from repeated loading and unloading, can be addressed by regular inspection and replacement of the eye bolt if signs of wear are detected.

Maintenance Tips

Regular inspection and maintenance of the Cummins 3014232 Eye Bolt are vital for ensuring its longevity and safe operation. Inspect the eye bolt for signs of corrosion, wear, or damage before each use. Clean the bolt and its surrounding area to remove any debris that could affect its performance. Lubricating the threads periodically can also help maintain its functionality.

Safety Considerations

When using the Cummins 3014232 Eye Bolt, it is important to adhere to safety guidelines to prevent accidents. Always operate within the specified load limits to avoid overloading the bolt. Use the eye bolt only in scenarios for which it is designed, and avoid modifying it in any way. Be aware of potential hazards such as sudden load shifts or environmental factors that could compromise the bolt’s integrity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s commitment to innovation and quality ensures that its products, including the Cummins 3014232 Eye Bolt, meet the demanding requirements of commercial truck applications 3.

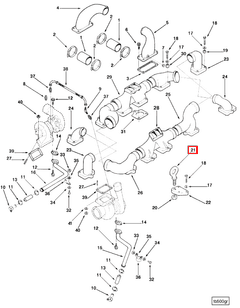

Cummins Eye Bolt 3014232 in V28 Engines

The Cummins Eye Bolt 3014232 is a critical component in the V28 engine series, designed to provide secure and reliable fastening in various engine applications. This part is integral to the engine’s assembly and maintenance, ensuring that components remain firmly in place under operational stresses.

In the V28 engine, the Eye Bolt 3014232 is typically used in areas where a strong, threaded fastener is required. Its robust design and high-quality material make it suitable for withstanding the demanding conditions within the engine. The eye bolt’s primary function is to provide a secure connection point, often used to attach engine mounts, brackets, or other structural elements.

The precision engineering of the Cummins Eye Bolt 3014232 ensures compatibility with the V28 engine’s specifications, allowing for easy installation and reliable performance. This part is essential for maintaining the integrity of the engine’s assembly, contributing to the overall durability and efficiency of the V28 engine series.

Role of Part 3014232 Eye Bolt in Engine Systems

The part 3014232 Eye Bolt is integral to several components within engine systems, providing essential support and secure connections.

Connection Points

The Eye Bolt is primarily used at various connection points where secure attachment is necessary. It ensures that components are firmly held in place, reducing the risk of detachment during operation.

Exhaust Outlet and Manifold

In the exhaust system, the Eye Bolt plays a significant role in securing the exhaust outlet and the exhaust manifold. It helps maintain the integrity of the exhaust path, ensuring that gases are directed away from the engine efficiently.

Exhaust Manifold Conversion Kit

When installing an exhaust manifold conversion kit, the Eye Bolt is used to secure the new manifold to the engine block or other structural components. This ensures a stable and leak-free connection, which is vital for the proper functioning of the exhaust system.

Exhaust Outlet Bracket

The Eye Bolt is also employed in the exhaust outlet bracket to provide a robust connection between the exhaust outlet and the vehicle’s frame or chassis. This connection is essential for withstanding the vibrations and stresses encountered during engine operation.

PDC (Programmable Diagnostic Controller)

In systems involving a Programmable Diagnostic Controller (PDC), the Eye Bolt may be used to secure sensor brackets or other diagnostic equipment. This ensures that the PDC can accurately monitor and control engine parameters.

Lifting Bracket and Mounting

During maintenance or repair procedures, the Eye Bolt is often used in lifting brackets and their mounting points. This allows for safe and secure lifting of heavy engine components, facilitating easier and safer servicing.

Manifold and Exhaust

In both the manifold and the exhaust system, the Eye Bolt ensures that all components are tightly secured. This is important for maintaining the efficiency of the exhaust flow and preventing leaks that could affect engine performance.

Turbocharger

For turbocharged engines, the Eye Bolt is used to secure the turbocharger to the engine block or exhaust manifold. This ensures that the turbocharger remains stable under high-stress conditions, contributing to the overall reliability and performance of the engine.

Conclusion

The Cummins 3014232 Eye Bolt is a vital component in the operation and maintenance of commercial trucks and engine systems. Its robust design, high-strength materials, and precise engineering make it suitable for withstanding demanding conditions and ensuring secure connections. Regular maintenance and adherence to safety guidelines are essential for maximizing the longevity and reliability of this part.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.