This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

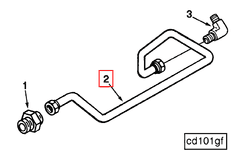

The Compressor Water Outlet Tube, part number 3012005, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is integral to the cooling systems of heavy-duty trucks, ensuring efficient operation and longevity of the engine.

Function and Operation

The Compressor Water Outlet Tube plays a role in the truck’s cooling system by facilitating the flow of coolant from the compressor to other parts of the engine. This ensures that the compressor remains at an optimal operating temperature, which is vital for its efficiency and durability. The tube is designed to handle the pressures and temperatures associated with the cooling system, ensuring a consistent and reliable flow of coolant 1.

Key Features

This Cummins part is constructed from high-quality materials that are resistant to corrosion and wear, ensuring durability in demanding environments. It features secure connection types that prevent leaks and maintain the integrity of the cooling system. The design includes precise engineering to ensure optimal coolant flow and compatibility with specific engine configurations 2.

Benefits

The use of the Compressor Water Outlet Tube offers several advantages. It enhances coolant flow, which contributes to more effective engine cooling. This, in turn, provides enhanced engine protection by maintaining optimal operating temperatures. Additionally, the tube contributes to the overall efficiency of the cooling system, which can lead to improved engine performance and longevity 3.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is vital to ensure it functions correctly within the cooling system. Installation procedures should follow manufacturer guidelines to ensure secure and leak-free connections. Compatibility with specific truck models and engine types should be verified to ensure optimal performance and integration within the system 4.

Maintenance and Troubleshooting

Regular maintenance of the Compressor Water Outlet Tube is important to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or leaks. Common issues may include blockages or connection failures, which can be diagnosed through visual inspections and pressure tests. Recommended solutions may involve cleaning, repairing, or replacing the tube as necessary.

Safety Considerations

When working with the Compressor Water Outlet Tube, it is important to observe safety practices to prevent accidents or damage. This includes handling the component with care to avoid damage and ensuring that all connections are secure before operating the engine. Additionally, it is important to follow operational safety measures to prevent coolant leaks or system failures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. Their product range includes a variety of components and systems designed to enhance the performance, efficiency, and durability of vehicles.

Conclusion

The Compressor Water Outlet Tube, part number 3012005, is a vital component for the efficient operation of heavy-duty truck engines. Its role in facilitating coolant flow ensures optimal engine temperature, contributing to engine efficiency and longevity. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the benefits of this Cummins part.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

Automotive Mechatronics Operational and Practical Issues Volume 1, BT Fijalkowski, Springer, 2011.

↩ -

Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves, Angelina Eret, Springer Nature, 2024.

↩ -

Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.