This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Seawater Connection Fitting 3010351 by Cummins is a specialized component designed for use in heavy-duty trucks, particularly those operating in environments where seawater is utilized for cooling or other processes. This fitting facilitates the connection between the truck’s cooling system and a seawater source, ensuring efficient operation and performance.

Basic Concepts of Seawater Connection Fittings

Seawater connection fittings are components used in marine and industrial applications to connect systems that require seawater for cooling, washing, or other processes. These fittings are designed to handle the corrosive nature of seawater while providing a secure and reliable connection. They are integral to the operation of systems that depend on seawater for efficient functioning 1.

Purpose of the 3010351 Seawater Connection Fitting

The 3010351 Seawater Connection Fitting is specifically designed to facilitate the operation of heavy-duty trucks by providing a reliable connection for seawater intake. This fitting is used in systems where seawater is required for cooling engines or other components, ensuring that the system operates efficiently and effectively.

Key Features

The 3010351 Seawater Connection Fitting features a robust design that includes a corrosion-resistant material composition, typically made from durable metals or high-grade plastics. Its design elements are tailored to withstand the harsh conditions associated with seawater exposure, ensuring longevity and reliable performance. Unique attributes such as reinforced seals and easy-to-use connectors enhance its functionality and ease of installation.

Benefits of Using the 3010351 Seawater Connection Fitting

Utilizing the 3010351 Seawater Connection Fitting offers several advantages. These include improved efficiency in seawater-based cooling systems, enhanced reliability due to its durable construction, and ease of installation thanks to its user-friendly design. Additionally, the fitting’s corrosion-resistant properties contribute to its longevity, reducing the need for frequent replacements.

Installation Process

Installing the 3010351 Seawater Connection Fitting involves several steps to ensure a secure and efficient connection. Begin by identifying the correct location for the fitting within the truck’s cooling system. Use the appropriate tools to connect the fitting to the seawater intake and the truck’s cooling system, ensuring all connections are tight and secure. Additional components, such as hoses or clamps, may be required to complete the installation.

Maintenance Tips

To ensure the longevity and optimal performance of the 3010351 Seawater Connection Fitting, regular maintenance is recommended. This includes inspecting the fitting for signs of corrosion or wear, cleaning the fitting and surrounding areas to prevent buildup, and checking all connections for tightness. Performing these maintenance practices will help maintain the efficiency and reliability of the fitting.

Troubleshooting Common Issues

Common issues with the 3010351 Seawater Connection Fitting may include leaks, corrosion, or connection failures. To address these problems, first, identify the source of the issue. For leaks, ensure all connections are tight and inspect for damage. Corrosion can be mitigated by cleaning the fitting and applying a protective coating. Connection failures may require reinstallation or replacement of the fitting.

Safety Considerations

When installing, maintaining, or troubleshooting the 3010351 Seawater Connection Fitting, it is important to observe safety guidelines. This includes wearing appropriate personal protective equipment, ensuring the truck is turned off and cooled down before beginning work, and following all manufacturer instructions. Additionally, be aware of the potential for electrical hazards if the fitting is used in conjunction with electrical components.

Environmental Impact

The use of seawater connection fittings, including the 3010351 model, involves environmental considerations. These fittings are designed to minimize the environmental impact by ensuring efficient use of seawater and reducing the risk of leaks or spills. The corrosion-resistant materials used in the fitting’s construction also contribute to its longevity, reducing the need for frequent replacements and associated waste.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation, quality, and sustainability in the automotive and engine manufacturing industry. The company’s product range includes engines for on-highway and off-highway applications, as well as filtration and emission solutions designed to meet the needs of a variety of industries 2.

Seawater Connection Fitting for Cummins Engines

The Seawater Connection Fitting, part number 3010351, is a critical component in the marine engine systems, particularly for the Cummins N14 MECHANICAL and NH/NT 855 engines. This fitting is essential for the proper functioning of the engine’s cooling system, ensuring that seawater can be efficiently circulated to maintain optimal operating temperatures.

In the Cummins N14 MECHANICAL engine, the seawater connection fitting is integral to the cooling system’s design. It allows for the intake of seawater, which is then pumped through the engine’s cooling passages to dissipate heat generated during operation. This fitting must be robust and reliable, as it is exposed to the harsh marine environment, including saltwater corrosion and varying temperatures.

Similarly, for the NH/NT 855 engine, the seawater connection fitting plays a pivotal role in the cooling mechanism. This engine, known for its durability and efficiency, relies on the precise and consistent flow of seawater to maintain its performance. The fitting ensures that the seawater is directed correctly into the engine’s cooling system, preventing any potential leaks or inefficiencies that could compromise the engine’s operation.

Both engines benefit from the use of high-quality materials and precise engineering in the design of the seawater connection fitting. This ensures that the fitting can withstand the rigors of marine environments while providing a secure and reliable connection for the seawater flow. The fitting’s design also facilitates easy maintenance and replacement, which is crucial for the longevity and reliability of the engines.

Role of Part 3010351 Seawater Connection Fitting in Engine Systems

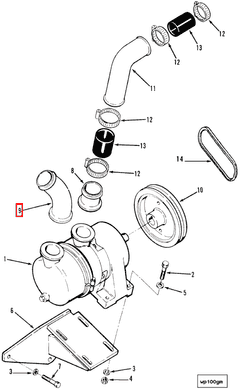

The Part 3010351 Seawater Connection Fitting is an integral component in the efficient operation of marine engine systems, particularly in the context of the pump and raw water systems.

In the pump system, the Seawater Connection Fitting facilitates the secure and reliable connection between the pump and the seawater intake. This ensures a steady and uninterrupted flow of seawater into the pump, which is essential for the pump’s operation. The fitting’s design allows for easy installation and removal, which is beneficial during maintenance or repair procedures. It also helps in preventing leaks, which could lead to inefficient pump performance or potential damage to the engine system.

In the raw water system, the Seawater Connection Fitting plays a significant role in maintaining the integrity of the system. It connects the raw water intake to the various components within the system, ensuring a consistent flow of seawater. This is particularly important for cooling purposes, as the raw water system is often used to cool the engine and other components. The fitting’s robust construction withstands the corrosive nature of seawater, ensuring long-term reliability and performance.

Overall, the Part 3010351 Seawater Connection Fitting is a key component in ensuring the efficient and reliable operation of marine engine systems. Its role in facilitating secure connections and maintaining system integrity is invaluable in the demanding environment of marine engineering.

Conclusion

The 3010351 Seawater Connection Fitting by Cummins is a vital component for heavy-duty trucks and marine engines that rely on seawater for cooling. Its robust design, corrosion-resistant materials, and ease of installation make it an essential part of the cooling system. Regular maintenance and proper installation are crucial for ensuring the longevity and efficiency of this Cummins part. By understanding its role and benefits, users can better maintain their systems and ensure optimal performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.