This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Sea Water Connection 3008874 is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is designed to facilitate the connection between the sea water cooling system and the engine of heavy-duty trucks. Cummins is renowned for its commitment to quality and innovation in automotive components, ensuring that their products meet the rigorous demands of heavy-duty applications 1.

Basic Concepts of Sea Water Connection

A Sea Water Connection is a vital component in the cooling system of trucks, particularly those used in marine or other environments where sea water is utilized for cooling purposes. It functions by allowing sea water to flow into the engine’s cooling system, where it absorbs heat from the engine and then is expelled, thereby maintaining optimal engine temperature. The principles behind its operation involve heat exchange and fluid dynamics, ensuring efficient cooling under demanding conditions 2.

Purpose of the 3008874 Sea Water Connection

The 3008874 Sea Water Connection plays a role in the engine cooling system by providing a secure and efficient pathway for sea water to enter and exit the system. This connection is integral to maintaining the engine’s temperature within safe operating limits, especially in environments where traditional cooling methods may not be as effective.

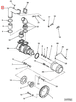

Key Features

The 3008874 Sea Water Connection is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials resistant to corrosion and wear, ensuring longevity in harsh environments. The design includes precise fittings and connections to prevent leaks and ensure a secure attachment to the engine’s cooling system. Additionally, it may feature unique attributes such as anti-fouling coatings to prevent the buildup of marine organisms, which can impede water flow 3.

Benefits

The use of the 3008874 Sea Water Connection offers several benefits, including improved cooling efficiency due to its design and materials. Its durability ensures long-term reliability, reducing the need for frequent replacements. The connection’s efficiency in heat exchange contributes to the overall performance and longevity of the engine.

Installation Process

Installing the 3008874 Sea Water Connection requires careful attention to detail to ensure a secure and leak-free connection. The process involves preparing the connection points on the engine, aligning the Sea Water Connection with these points, and securing it in place using the appropriate tools. It is important to follow manufacturer guidelines to ensure proper installation.

Maintenance Tips

Regular maintenance of the 3008874 Sea Water Connection is crucial for ensuring optimal performance and longevity. This includes periodic inspections for signs of wear or corrosion, cleaning the connection to remove any buildup that could impede water flow, and ensuring all connections are secure and leak-free. Adhering to these maintenance practices can help prevent issues and extend the component’s lifespan.

Troubleshooting Common Issues

Common issues with the 3008874 Sea Water Connection may include leaks, reduced cooling efficiency, or corrosion. Troubleshooting these problems involves inspecting the connection for physical damage, ensuring all fittings are secure, and cleaning or replacing the connection if necessary. Addressing these issues promptly can help maintain the efficiency and reliability of the engine’s cooling system.

Safety Considerations

When working with the 3008874 Sea Water Connection, it is important to observe safety guidelines to prevent injury and ensure the component’s proper function. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer instructions for installation and maintenance.

Environmental Impact

The use of sea water in cooling systems presents environmental considerations, particularly concerning the potential for marine life to be affected by the system’s operation. The design of the 3008874 Sea Water Connection aims to mitigate these effects by ensuring efficient water flow and minimizing the risk of leaks, which could harm marine ecosystems.

Cummins Overview

Cummins has a long-standing reputation in the industry for manufacturing high-quality automotive components. Their commitment to innovation and quality is evident in their product line, which includes a wide range of parts designed to meet the demands of heavy-duty applications. Cummins’ focus on research and development ensures that their products, like the 3008874 Sea Water Connection, are at the forefront of technology and reliability in the automotive sector.

Integration with Cummins Marine Engines

K19 Series

The Sea Water Connection part 3008874 is specifically engineered to fit the K19 series of Cummins marine engines. This part ensures that the engine receives a steady flow of seawater, which is essential for maintaining optimal operating temperatures and preventing overheating. The design of the part allows for a secure and leak-proof connection, which is crucial for the longevity and performance of the engine.

Other Cummins Marine Engines

While the primary focus is on the K19 series, the Sea Water Connection part 3008874 is also compatible with other Cummins marine engines. This compatibility extends to various models within the Cummins marine engine lineup, ensuring that the part can be used across different engine types without compromising on performance or reliability.

Grouping by Application

The Sea Water Connection part 3008874 is grouped by its application in marine environments. This part is essential for engines used in boats, ships, and other marine vessels where seawater is used for cooling. The design and material of the part are specifically chosen to withstand the harsh conditions of marine environments, ensuring durability and long-term performance.

Installation and Maintenance

Proper installation of the Sea Water Connection part 3008874 is crucial for the efficient operation of Cummins marine engines. This part should be installed by trained professionals who understand the specific requirements of marine engine installations. Regular maintenance and inspection of this part are also necessary to ensure that it continues to function correctly and prevent any potential issues that could affect engine performance.

Role of Part 3008874 Sea Water Connection in Engine Systems

The Part 3008874 Sea Water Connection is integral to the efficient operation of several marine engine components, ensuring optimal performance and longevity.

Integration with Heat Exchanger

In marine engines, the heat exchanger is responsible for regulating the temperature of the engine coolant. The Sea Water Connection facilitates the flow of raw water from the surrounding marine environment into the heat exchanger. This raw water absorbs excess heat from the engine coolant, which is then expelled back into the sea. The consistent flow provided by the Sea Water Connection ensures that the heat exchanger maintains an effective temperature differential, enhancing the engine’s thermal efficiency.

Functionality in Kit 1-Heat Exchanger

When incorporated into Kit 1-Heat Exchanger, the Sea Water Connection plays a pivotal role in the assembly and operation of the kit. It ensures a secure and leak-free connection between the raw water source and the heat exchanger components. This is essential for the kit to function as intended, providing reliable cooling and preventing potential overheating issues that could lead to engine damage.

Interaction with Raw Water Pump

The Raw Water Pump is designed to circulate raw water through the engine’s cooling system. The Sea Water Connection acts as the initial point of entry for this water, directing it from the marine environment into the pump. This uninterrupted flow is vital for the pump’s operation, allowing it to effectively draw in and circulate water throughout the cooling system. The connection’s design ensures minimal resistance and maximum flow, supporting the pump’s efficiency.

Ensuring Efficient Raw Water Circulation

In the broader context of the engine’s raw water system, the Sea Water Connection is the gateway through which raw water enters the system. Its proper function is essential for maintaining a consistent and efficient circulation of raw water. This circulation is necessary not only for cooling purposes but also for other systems that rely on raw water, such as aftercoolers and intercoolers in turbocharged engines.

By ensuring a reliable connection, the Sea Water Connection supports the overall integrity and performance of the engine’s cooling system, contributing to the engine’s durability and operational efficiency.

Conclusion

The 3008874 Sea Water Connection by Cummins is a critical component in the cooling systems of heavy-duty trucks and marine engines. Its design, functionality, and integration with various engine components ensure efficient cooling, durability, and long-term performance. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.