This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

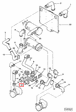

The Sea Water Connection 3008823 is a component designed by Cummins for use in heavy-duty trucks and marine engines. Its purpose is to facilitate the connection of sea water to the engine’s cooling system. This part plays a role in ensuring that the engine operates within optimal temperature ranges, particularly in marine environments where sea water is utilized for cooling 3.

Basic Concepts of Sea Water Connection

Sea water connections are integral to cooling systems in marine and heavy-duty truck applications. They function by allowing sea water to circulate through the engine’s cooling passages, absorbing heat and dissipating it back into the surrounding water. This process is vital for maintaining engine temperature and preventing overheating, which can lead to engine damage 1.

Purpose of the 3008823 Sea Water Connection

The 3008823 Sea Water Connection is specifically designed to connect the sea water supply to the truck’s engine cooling system. It facilitates the flow of sea water to the engine, ensuring efficient heat exchange. This connection is crucial for trucks operating in marine environments, where traditional freshwater cooling systems may not be feasible 2.

Key Features

The 3008823 Sea Water Connection is characterized by its robust design and the use of high-quality materials. It is constructed to withstand the corrosive effects of sea water, ensuring durability and reliability. The connection features a secure fitting mechanism that prevents leaks and ensures a consistent flow of cooling water to the engine 4.

Benefits

The 3008823 Sea Water Connection offers several advantages. It enhances engine cooling efficiency by providing a direct and reliable connection to the sea water supply. Its durable construction ensures long-term performance in harsh marine environments. Additionally, the design of the connection allows for ease of installation and maintenance, reducing downtime and operational costs 3.

Installation Process

Installing the 3008823 Sea Water Connection involves several steps to ensure a secure and effective fit. Begin by ensuring the engine cooling system is clean and free of debris. Use the appropriate tools to connect the sea water supply line to the 3008823 fitting, following the manufacturer’s guidelines for torque specifications. Verify the connection for leaks and secure all components according to best practices 4.

Maintenance Tips

Regular maintenance of the 3008823 Sea Water Connection is important for ensuring its longevity and optimal performance. Periodic inspections should be conducted to check for signs of corrosion or wear. Cleaning the connection and its surrounding components can prevent buildup that may impede water flow. Replace any worn or damaged parts promptly to maintain the integrity of the cooling system 1.

Troubleshooting Common Issues

Common issues with the 3008823 Sea Water Connection may include leaks, corrosion, or blockages. To address leaks, inspect the connection for loose fittings or damaged components and tighten or replace as necessary. Corrosion can be mitigated by regular cleaning and the application of protective coatings. Blockages may require disassembling the connection to clear debris from the water passages 2.

Safety Considerations

When working with the 3008823 Sea Water Connection, it is important to observe safety protocols. Use personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow manufacturer guidelines for handling and installation to ensure safe operation. Adhere to all safety precautions to prevent accidents and ensure a secure working environment 4.

Environmental Impact

The use of sea water connections in cooling systems has environmental implications. While sea water is a readily available resource, its use can introduce contaminants into marine ecosystems. Implementing sustainable practices, such as regular maintenance to prevent leaks and using environmentally friendly materials, can help minimize the ecological footprint of these systems 3.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to innovation and quality. With a rich history in the industry, Cummins has established a reputation for producing reliable and high-performance automotive components. The company’s dedication to advancing technology and meeting customer needs is evident in its wide range of products, including the 3008823 Sea Water Connection 4.

Sea Water Connection Part 3008823 for Cummins Engines

The Sea Water Connection part 3008823, manufactured by Cummins, is a critical component designed to interface with various Cummins marine engines. This part ensures the proper flow of seawater to the engine’s cooling system, which is essential for maintaining optimal operational temperatures and preventing overheating 4.

K38 Engines

For the K38 series engines, the Sea Water Connection part 3008823 is engineered to fit seamlessly with the engine’s design. This part is crucial for the efficient operation of the engine’s cooling system, ensuring that seawater is directed correctly to the heat exchangers and other cooling components. The design of this part ensures a secure and leak-proof connection, which is vital for the longevity and reliability of the engine 4.

K50 Engines

Similarly, the Sea Water Connection part 3008823 is also compatible with the K50 series engines. In these engines, the part is designed to integrate with the engine’s architecture, providing a reliable pathway for seawater to flow through the cooling system. The precision engineering of this component ensures that it meets the stringent demands of marine environments, where reliability and durability are paramount 4.

Grouping of Engines

Both the K38 and K50 engines benefit from the use of the Sea Water Connection part 3008823 due to its universal design features. This part is crafted to fit a range of Cummins marine engines, ensuring that it can be used across different engine models without compromising on performance. The compatibility of this part with both the K38 and K50 engines highlights its versatility and importance in maintaining the efficiency and reliability of Cummins marine engines 4.

Role of Part 3008823 Sea Water Connection in Engine Systems

The part 3008823 Sea Water Connection is an integral component in the efficient operation of marine engine systems. It facilitates the flow of raw water from the sea into the engine’s cooling system, ensuring that the engine remains at optimal operating temperatures 4.

Integration with Raw Water Inlet

The Sea Water Connection interfaces directly with the raw water inlet. This connection point is where seawater enters the engine’s cooling system. The raw water inlet relies on a secure and leak-free connection to the Sea Water Connection to maintain a consistent flow of cooling water. This is essential for dissipating heat generated by the engine, preventing overheating and potential damage 4.

Function within the Heat Exchanger

Once seawater enters through the raw water inlet via the Sea Water Connection, it flows into the heat exchanger. The heat exchanger is a vital component that transfers heat from the engine’s coolant to the incoming seawater. The Sea Water Connection ensures a steady supply of seawater to the heat exchanger, allowing it to effectively cool the engine coolant. This process is fundamental to maintaining the engine’s temperature within safe operating limits 4.

Overall System Efficiency

The efficiency of the entire cooling system depends on the reliable performance of the Sea Water Connection. By providing a consistent and uninterrupted flow of seawater, it supports the heat exchanger in its role of cooling the engine coolant. This, in turn, helps maintain the engine’s performance and longevity. The Sea Water Connection is a key element in the seamless operation of the engine’s cooling system, working in concert with the raw water inlet and heat exchanger to ensure the engine operates efficiently and reliably 4.

Conclusion

The 3008823 Sea Water Connection by Cummins is a vital component in the cooling systems of heavy-duty trucks and marine engines. Its robust design, durable materials, and secure fitting mechanism ensure efficient heat exchange and reliable operation in harsh marine environments. Regular maintenance and adherence to safety protocols are essential for maximizing the performance and longevity of this part. By understanding the role and benefits of the 3008823 Sea Water Connection, users can ensure optimal engine performance and contribute to sustainable marine operations.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ ↩ -

Understanding Automotive Electronics, William B. Ribbens, Elsevier Science, 2003

↩ ↩ -

Automotive Technician Training Theory, Tom Denton and Hayley Pells, Routledge, 2022

↩ ↩ ↩ -

Service Manual (4310575), QSB4.5 CM2250 EC, Cummins Inc.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.