3003814

Lubricating Oil Cooler

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

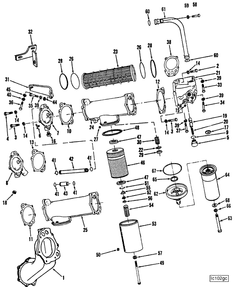

The Cummins Lubricating Oil Cooler, part number 3003814, is designed to regulate the temperature of lubricating oil within heavy-duty truck engines. This component ensures that the oil remains within optimal temperature ranges, contributing to efficient engine operation and longevity. The importance of this part in heavy-duty truck maintenance and performance cannot be overstated, as it plays a crucial role in the overall reliability and efficiency of the engine system.

Basic Concepts of Lubricating Oil Coolers

A Lubricating Oil Cooler is a heat exchanger designed to remove excess heat from the lubricating oil circulating within an engine. It functions by transferring heat from the oil to a cooler medium, typically air or coolant, maintaining the oil at a temperature that ensures proper viscosity and performance. The principles of heat exchange involved include conduction, convection, and in some cases, radiation, all of which facilitate the efficient transfer of heat away from the oil 1.

Role of the 3003814 Lubricating Oil Cooler in Truck Operation

The 3003814 Lubricating Oil Cooler ensures optimal engine performance and longevity by maintaining the lubricating oil within the desired temperature range. This is achieved through the efficient removal of excess heat, preventing the oil from becoming too thin at high temperatures or too thick at low temperatures. Proper oil temperature is vital for reducing friction, wear, and the formation of harmful deposits within the engine, thereby contributing to consistent engine performance and extended component life 2.

Key Features of the 3003814 Lubricating Oil Cooler

The design elements and materials used in the 3003814 Lubricating Oil Cooler contribute to its efficiency and durability. Constructed from high-quality materials resistant to corrosion and wear, this part ensures long-term reliability. The cooler’s design maximizes the surface area for heat exchange, enhancing its ability to dissipate heat effectively. Additionally, it is engineered to integrate seamlessly with Cummins engines, ensuring compatibility and optimal performance.

Benefits of Using the 3003814 Lubricating Oil Cooler

The advantages provided by the 3003814 Lubricating Oil Cooler include improved engine reliability, extended oil life, and enhanced overall performance. By maintaining the lubricating oil at the correct temperature, it helps to reduce engine wear, improve fuel efficiency, and extend the intervals between oil changes. This contributes to lower maintenance costs and increased uptime for heavy-duty trucks 3.

Installation and Integration

Proper installation procedures for the 3003814 Lubricating Oil Cooler ensure it is correctly integrated into the truck’s engine system. It is important to follow manufacturer guidelines for installation, which may include securing the cooler in the designated location, ensuring proper alignment with oil lines, and verifying all connections are secure and leak-free. Correct installation is key to ensuring the cooler operates efficiently and effectively within the engine system.

Maintenance and Troubleshooting

Routine maintenance practices for the 3003814 Lubricating Oil Cooler include regular inspection for signs of wear, corrosion, or leaks. It is also important to ensure that the cooler’s fins and tubes are free from debris and obstructions that could impede airflow and heat exchange efficiency. Troubleshooting tips for common issues may involve checking for proper oil flow, verifying the integrity of connections, and addressing any signs of damage or malfunction promptly to prevent further complications.

Performance Monitoring

Methods for monitoring the performance of the 3003814 Lubricating Oil Cooler include observing indicators of efficient operation, such as stable oil temperatures within the recommended range, and signs of potential malfunction, such as unusual noises, leaks, or fluctuations in oil temperature. Regular monitoring and maintenance can help identify issues early, ensuring the cooler continues to operate efficiently and contribute to the overall performance and reliability of the engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the automotive industry, Cummins is committed to producing high-quality engine components that meet the demanding requirements of heavy-duty applications. The company’s focus on quality, performance, and customer satisfaction has established it as a trusted name in the production of engine parts, including the 3003814 Lubricating Oil Cooler.

Conclusion

The Cummins 3003814 Lubricating Oil Cooler is a vital component in maintaining the efficiency and longevity of heavy-duty truck engines. By ensuring that the lubricating oil remains within optimal temperature ranges, this part contributes to reduced engine wear, improved fuel efficiency, and extended oil life. Proper installation, regular maintenance, and performance monitoring are essential to maximizing the benefits of this cooler, ultimately leading to enhanced engine performance and reliability.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair (2nd ed.). Cengage Learning.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.