This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

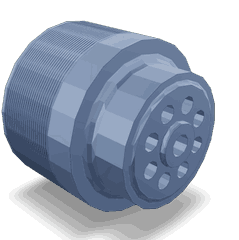

The Cummins 3003344 Crankshaft Pulley is a vital component designed for use in commercial trucks. It facilitates the transfer of power from the engine to various auxiliary systems, playing a significant role in the operation of these vehicles. Understanding its function and importance provides valuable insights into the overall performance and maintenance of commercial trucks.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is attached to the front of an engine’s crankshaft. Its primary function is to drive the engine’s accessory belt, powering components such as the alternator, water pump, and air conditioning compressor 1. In the context of a truck’s powertrain, the crankshaft pulley ensures that these systems receive the necessary power to operate efficiently.

Purpose of the Cummins 3003344 Crankshaft Pulley

This Cummins part connects the crankshaft to the accessory belt, allowing for the transfer of rotational force from the engine to the various accessories that support its function. The pulley also helps to reduce vibrations caused by the engine’s operation, contributing to a smoother running engine and potentially extending the lifespan of connected components 2.

Key Features

The 3003344 Crankshaft Pulley is constructed with high-quality materials to ensure durability and performance. Its design includes a robust outer ring and a dampening core, which work together to absorb vibrations and provide a stable platform for the accessory belt. The pulley is engineered to meet the demanding requirements of commercial truck applications, offering reliable performance under various operating conditions 3.

Benefits

This part offers several advantages. It contributes to improved engine performance by ensuring efficient power transfer to accessories. Its durable construction and vibration dampening features enhance the longevity of the engine and connected components. Additionally, the pulley’s design supports overall engine efficiency by minimizing energy loss during operation 4.

Installation Process

Installing the 3003344 Crankshaft Pulley requires careful attention to detail. The process involves aligning the pulley with the crankshaft, securing it in place with the appropriate fasteners, and ensuring that the accessory belt is correctly routed and tensioned. Proper tools and equipment, such as a torque wrench and belt tensioner, are necessary to complete the installation successfully.

Common Issues and Troubleshooting

Typical problems associated with crankshaft pulleys include wear, cracks, and failure of the dampening core. Diagnosing issues may involve visual inspection for physical damage, checking for excessive vibrations, or monitoring engine performance. Recommended troubleshooting steps include replacing worn components, ensuring proper belt tension, and addressing any underlying engine issues that may contribute to pulley failure.

Maintenance Tips

Regular maintenance of the 3003344 Crankshaft Pulley is important for ensuring longevity and optimal performance. This includes inspecting the pulley and accessory belt for signs of wear, ensuring proper belt tension, and addressing any vibrations or performance issues promptly. Following the manufacturer’s recommended maintenance schedule can help prevent premature failure and ensure the pulley continues to operate efficiently.

Compatibility and Applications

The 3003344 Crankshaft Pulley is designed for use with specific truck models and engine types. Ensuring compatibility is important for optimal performance and longevity. Detailed information on compatible applications can be found in the product documentation provided by Cummins Inc.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is committed to providing reliable and efficient power solutions for its customers. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Crankshaft Pulley (Part 3003344) Compatibility with Cummins Engines

The Cummins crankshaft pulley part number 3003344 is designed to be compatible with a range of Cummins engines, ensuring reliable and efficient operation across various applications. This part is integral to the engine’s operation, as it interfaces directly with the crankshaft and the engine’s accessory drive system.

K38 Engines

For the K38 engine series, the 3003344 crankshaft pulley is engineered to fit seamlessly. This series of engines is known for its robust design and high performance, making the pulley’s precise fit crucial for maintaining optimal engine function. The K38 engines benefit from the pulley’s ability to transfer power efficiently from the crankshaft to the engine’s accessories, such as the alternator and air conditioning compressor.

K50 Engines

Similarly, the K50 engine series is another beneficiary of the 3003344 crankshaft pulley. The K50 engines are recognized for their versatility and adaptability in various industrial and commercial applications. The compatibility of the 3003344 pulley with the K50 engines ensures that these engines can operate smoothly and reliably, with the pulley providing the necessary connection between the crankshaft and the engine’s ancillary systems.

Grouping of Engines

When considering the compatibility of the 3003344 crankshaft pulley with the K38 and K50 engines, it is evident that Cummins has designed this part to serve multiple engine series effectively. The shared design and engineering principles ensure that the pulley can be used across different engine models without compromising performance or durability. This compatibility is particularly beneficial for maintenance and repair operations, as it allows for a standardized part to be used across various engine types, simplifying inventory management and reducing downtime.

Role of Part 3003344 Crankshaft Pulley in Engine Systems

The Part 3003344 Crankshaft Pulley is an integral component in the efficient operation of various engine systems. Its primary function is to drive multiple auxiliary components through a series of belts or chains. Here’s how it interfaces with the provided components:

Interaction with EBM-Damper

The Crankshaft Pulley works in conjunction with the Engine Balancer Module (EBM) damper to maintain smooth engine operation. The EBM-damper is designed to reduce torsional vibrations that occur during the engine’s operation. As the Crankshaft Pulley rotates, it transmits power to the EBM-damper, which in turn helps to stabilize the crankshaft’s rotation. This interaction ensures that the engine runs more smoothly and with reduced wear on internal components.

Managing Vibration

One of the key roles of the Crankshaft Pulley is to manage vibration within the engine system. When the engine fires, it generates a significant amount of vibration. The Crankshaft Pulley, when properly aligned and balanced, helps to transmit this motion efficiently while minimizing the transfer of unwanted vibrations to other engine components. This is essential for maintaining the longevity and performance of the engine.

Coordination with Vibration Damper

The Crankshaft Pulley also interacts with the vibration damper, which is often integrated into the pulley itself or attached directly to the crankshaft. The vibration damper absorbs and dissipates the torsional vibrations generated by the engine’s combustion cycles. As the Crankshaft Pulley rotates, it ensures that the vibration damper functions effectively, thereby protecting the crankshaft and other rotating assemblies from excessive vibration. This results in a more stable and reliable engine performance.

Conclusion

In summary, the Part 3003344 Crankshaft Pulley plays a significant role in driving auxiliary components, managing engine vibrations, and ensuring the efficient operation of the EBM-damper and vibration damper. Its proper function is essential for the overall performance and durability of the engine system.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.