This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

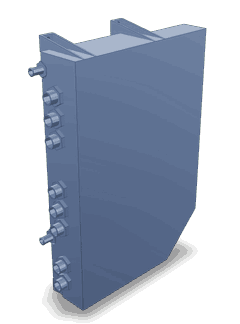

The Inverter, TRC 300111 by Cummins, is a sophisticated component designed to enhance the electrical system of commercial trucks. Its primary function is to convert direct current (DC) power from the truck’s battery into alternating current (AC) power, which is necessary for operating various electrical appliances and systems within the vehicle. This conversion capability is significant in commercial truck operations, where reliable and efficient power management is essential for maintaining productivity and ensuring the comfort of the driver 1.

Basic Concepts of Inverters in Trucks

An inverter is an electronic device that transforms DC power into AC power. In the context of a truck’s electrical system, the inverter plays a role by enabling the use of AC-powered devices, such as refrigeration units, air conditioning systems, and electronic equipment, which are commonly used in commercial trucking. The inverter ensures that these devices receive a stable and consistent power supply, regardless of the truck’s engine status 2.

Purpose of the Inverter, TRC 300111

The Inverter, TRC 300111 is specifically engineered to support the demanding power requirements of commercial trucks. It facilitates the operation of high-power AC devices, ensuring that they function efficiently and reliably. This inverter is integral to systems that require a steady AC power source, such as climate control units, onboard entertainment systems, and other auxiliary electrical equipment. By providing a consistent power output, the TRC 300111 contributes to the overall functionality and comfort of the truck’s interior environment 3.

Key Features

The Inverter, TRC 300111 boasts several key features that enhance its performance and reliability. These include a high power output capacity, which allows it to support multiple high-demand devices simultaneously. Its efficiency is notable, ensuring minimal energy loss during the conversion process. The design of the inverter is robust, built to withstand the harsh conditions often encountered in commercial trucking. Additionally, it incorporates advanced technological aspects such as smart monitoring systems, which provide real-time data on its operation and performance 4.

Benefits of Using the Inverter, TRC 300111

Utilizing the Inverter, TRC 300111 offers several advantages. It enhances the efficiency of the truck’s electrical system by providing a reliable AC power source. This reliability contributes to the overall performance of the truck, ensuring that electrical systems operate smoothly and without interruption. Furthermore, the inverter’s efficiency leads to potential cost savings by optimizing energy use. Its robust design and advanced features also contribute to increased durability and reduced maintenance requirements 5.

Integration with Truck Systems

The Inverter, TRC 300111 seamlessly integrates with other truck systems, including the battery, engine, and auxiliary power units. This integration ensures that the inverter operates in harmony with the truck’s electrical system, providing a stable power supply to AC-powered devices. Its compatibility with various truck systems enhances the overall performance of the vehicle, ensuring that all electrical components function efficiently and reliably 6.

Troubleshooting and Maintenance

To ensure optimal performance and longevity of the Inverter, TRC 300111, it is important to address common issues promptly. Regular maintenance practices, such as checking for loose connections, ensuring proper ventilation, and monitoring the inverter’s performance, are essential. Troubleshooting steps may include verifying the input voltage, checking for software updates, and consulting the manufacturer’s guidelines for specific issues. Adhering to these practices helps maintain the inverter’s efficiency and reliability 7.

Safety Considerations

When installing, operating, and maintaining the Inverter, TRC 300111, it is imperative to follow safety protocols. These include ensuring that the inverter is properly installed according to the manufacturer’s instructions, using the correct wiring and connections, and adhering to safety guidelines when working with electrical systems. Additionally, operators should be aware of the inverter’s operating limits and avoid overloading it to prevent damage and ensure safe usage 8.

Environmental Impact

The use of the Inverter, TRC 300111 contributes to environmental benefits by improving energy efficiency within the truck’s electrical system. Its efficient power conversion process reduces energy waste, leading to lower fuel consumption and decreased emissions. Furthermore, the inverter’s durability and reduced maintenance requirements contribute to a lower environmental footprint over its lifespan 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as a pioneer in the automotive and heavy-duty truck industries. The company’s product range includes engines, filtration systems, and power generation equipment, all designed with a commitment to innovation, quality, and sustainability. Cummins’ dedication to advancing technology and improving efficiency is evident in its comprehensive lineup of products, including the Inverter, TRC 300111 10.

Conclusion

The Inverter, TRC 300111 by Cummins is a vital component for enhancing the electrical systems of commercial trucks. Its ability to convert DC power into AC power supports the operation of various high-demand devices, contributing to the overall efficiency, comfort, and performance of the vehicle. With its robust design, advanced features, and integration capabilities, this part ensures reliable and efficient power management, making it an essential asset for commercial trucking operations.

-

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Garrett, TK, K Newton, and W Steeds. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Zhan, Quansheng, Eben Shengbo, and Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Cummins Inc. Service Manual (5579755).

↩ -

Cummins Inc. Service Manual (5579755).

↩ -

Cummins Inc. Service Manual (5579755).

↩ -

Cummins Inc. Service Manual (5579755).

↩ -

Cummins Inc. Service Manual (5579755).

↩ -

Cummins Inc. Service Manual (5579755).

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.