2899574

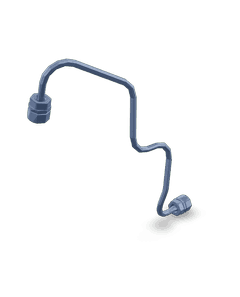

Injector Fuel Supply Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Fuel Supply Tube, part number 2899574, is a vital component in the fuel system of heavy-duty trucks. It ensures the efficient delivery of fuel from the tank to the injectors, which is essential for maintaining optimal engine performance. This part is designed to maintain consistent fuel pressure and flow, which are critical for the engine’s smooth and effective operation 1.

Function and Operation

The Injector Fuel Supply Tube operates by channeling fuel from the tank to the injectors within the engine system. It ensures that fuel is delivered under consistent pressure and flow, which is necessary for the injectors to function correctly. The tube’s design allows it to withstand the pressures and temperatures within the fuel system, ensuring reliable operation over time 2.

Key Features

The Cummins Injector Fuel Supply Tube is constructed from materials that offer durability and resistance to the harsh conditions within the fuel system. Its design includes features that enhance its performance and longevity, such as reinforced sections to handle high pressure and temperature fluctuations. These characteristics differentiate it from other components, providing a reliable solution for fuel delivery in heavy-duty applications 3.

Benefits

The use of the Cummins Injector Fuel Supply Tube offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered efficiently to the injectors. This efficient delivery also enhances engine performance, allowing the engine to operate more smoothly and with greater power. Additionally, the tube’s reliable design contributes to the overall reliability of the truck’s fuel system, reducing the likelihood of fuel-related issues 4.

Installation and Compatibility

Proper installation of the Injector Fuel Supply Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it functions as intended within the fuel system. Compatibility with various Cummins engine models and other relevant truck systems is an important consideration, ensuring that the tube fits and operates correctly within the intended application.

Maintenance and Troubleshooting

Routine maintenance of the Injector Fuel Supply Tube is important for its longevity and performance. This includes regular inspections for signs of wear or damage and ensuring that all connections are secure. Common issues may include leaks or blockages, which can be diagnosed through visual inspection and pressure testing. Troubleshooting steps may involve cleaning or replacing the tube if necessary, following manufacturer guidelines for safe and effective repair.

Safety Considerations

When working with the Injector Fuel Supply Tube, it is important to observe safety protocols and precautions. This includes adhering to manufacturer guidelines and industry standards to prevent accidents and ensure safe operation. Proper handling and installation procedures should be followed to avoid fuel leaks or other hazards associated with the fuel system.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related components, with a history of innovation and quality in the automotive industry. The company is known for its commitment to developing reliable and efficient engine solutions, catering to a wide range of applications. Cummins’ reputation for quality and customer satisfaction underscores its position as a trusted provider in the market.

Application in Cummins Engines

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

The Injector Fuel Supply Tube is integral to the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines. These engines are known for their robust design and high power output, making them suitable for heavy-duty applications. This part ensures that the fuel supply remains uninterrupted, which is crucial for the engines’ performance and longevity.

QSX11.9 CM2250 ECF

Similarly, the QSX11.9 CM2250 ECF engine also relies on the Injector Fuel Supply Tube. This engine is designed for applications that require a balance of power and efficiency. The fuel supply tube’s role in this engine is to maintain the precise fuel delivery necessary for its operation, ensuring that the engine runs smoothly and efficiently.

Importance of the Fuel Supply Tube

The Injector Fuel Supply Tube is a vital part of the engine’s fuel system. It connects the fuel pump to the injectors, ensuring that fuel is delivered at the correct pressure and flow rate. This component is designed to withstand the high pressures and temperatures found in the engine’s fuel system, ensuring durability and reliability.

Compatibility and Installation

When installing the Injector Fuel Supply Tube, it is essential to ensure that it is compatible with the specific engine model. Proper installation is crucial to avoid any fuel leaks or delivery issues, which can lead to engine performance problems. Technicians should follow the manufacturer’s guidelines and use the appropriate tools and techniques to ensure a secure and reliable installation.

Conclusion

The Cummins Injector Fuel Supply Tube (part number 2899574) plays a significant role in the fuel delivery process by providing a secure and pressurized pathway for fuel from the fuel rail to the injectors. Its design and construction ensure consistent fuel pressure and flow, contributing to the overall efficiency and performance of the engine. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this component in heavy-duty engine applications.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Zhan, Quansheng, Eben, Shengbo, and Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Arora, Shashank, Abkenar, Alireza Tashakori, and Jayasi, Shantha Gamini. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.