2899570

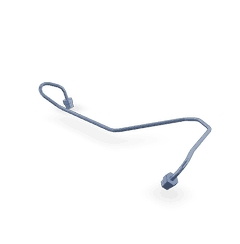

Injector Fuel Supply Tube

Cummins®

IN STOCK

4 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Fuel Supply Tube, identified by part number 2899570, is a critical component in the fuel system of heavy-duty trucks. Manufactured by Cummins Inc., a leader in the automotive industry known for its commitment to innovation and quality, this part ensures efficient fuel delivery within the engine system.

Function and Operation

The Injector Fuel Supply Tube operates by facilitating the transfer of fuel from the tank to the injectors within the engine. It plays a role in maintaining consistent fuel pressure and flow, which is vital for the proper functioning of the fuel injection system. This ensures that the engine receives the precise amount of fuel needed for combustion, contributing to overall engine performance and efficiency 1.

Key Features

The design and construction of the Injector Fuel Supply Tube incorporate several features that enhance its performance and durability. It is typically made from high-quality materials that resist corrosion and wear, ensuring longevity even under demanding conditions. The tube’s construction may include reinforced sections to withstand high fuel pressures and vibrations common in heavy-duty applications 2.

Benefits

Utilizing the Cummins Injector Fuel Supply Tube offers several advantages. It contributes to improved fuel efficiency by ensuring a consistent and precise fuel delivery to the injectors. This part is engineered for reliability, reducing the likelihood of fuel system failures. Additionally, its compatibility with Cummins engines ensures seamless integration and optimal performance 3.

Installation and Maintenance

Proper installation of the Injector Fuel Supply Tube is crucial for its effective operation. It should be securely fitted to prevent fuel leaks and ensure a stable connection within the fuel system. Regular maintenance practices, such as inspecting for signs of wear or damage and ensuring all connections are tight, can help maintain optimal performance and extend the tube’s lifespan.

Troubleshooting Common Issues

Common issues associated with the Injector Fuel Supply Tube may include fuel leaks or restricted flow. Diagnostic procedures should begin with a visual inspection of the tube and its connections for any visible damage or leaks. If a leak is detected, the affected section may need to be replaced. Restricted flow can often be resolved by cleaning or replacing the fuel filter, ensuring that the fuel system remains unobstructed.

Safety Considerations

When handling and working with the Injector Fuel Supply Tube, it is important to adhere to safety precautions. This includes working in a well-ventilated area to avoid inhaling fuel vapors, wearing appropriate personal protective equipment, and ensuring that all tools and equipment are in good condition to prevent accidents.

Environmental Impact

The use of the Cummins Injector Fuel Supply Tube contributes to reducing emissions by ensuring efficient fuel combustion. This part plays a role in promoting sustainable transportation practices by enhancing the overall efficiency of the fuel system, which can lead to lower fuel consumption and reduced environmental impact.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation, quality, and commitment to customer success. The company’s product offerings include a wide range of engines and components designed for heavy-duty applications, underscoring its reputation in the automotive industry.

Conclusion

The Cummins Injector Fuel Supply Tube (part 2899570) is a vital component in the fuel delivery system of heavy-duty engines. Its role in ensuring efficient and reliable fuel delivery contributes to the overall performance, efficiency, and reliability of the engine. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.