2899498

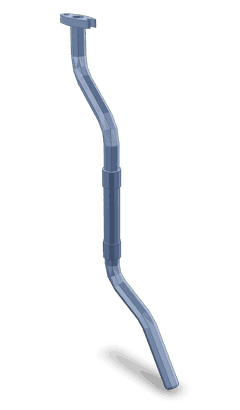

Tur Oil Drain Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tur Oil Drain Tube, part number 2899498, manufactured by Cummins, is a critical component in the maintenance of heavy-duty trucks. This tube is essential for the efficient drainage of used oil from the engine, facilitating timely and complete oil changes. Cummins, a prominent figure in the diesel engine and technology sector, emphasizes durability and efficiency in the production of this part, highlighting its importance in the maintenance of heavy-duty vehicles.

Function and Operation

The Tur Oil Drain Tube serves as a conduit within the engine system, specifically designed to aid in the oil drainage process. During an oil change, this tube allows for the swift and complete removal of old oil from the engine, ensuring that new oil is introduced into a clean environment. Proper oil drainage is crucial for maintaining engine health and performance, as it helps prevent the accumulation of contaminants and sludge that can negatively impact engine operation.

Key Features

The Tur Oil Drain Tube is designed with durability and efficiency in mind. Constructed from corrosion-resistant alloys, this Cummins part is built to withstand the harsh conditions found in heavy-duty truck engines. Its unique design elements enhance resistance to wear and corrosion, contributing to its overall performance and longevity. These features ensure that the tube can effectively meet the demanding requirements of commercial truck maintenance.

Benefits

Using the Tur Oil Drain Tube in heavy-duty trucks offers several advantages. It facilitates improved engine maintenance by enabling quicker and more complete oil changes. This efficiency not only saves time but also enhances engine protection by removing used oil, which may contain contaminants and breakdown products. The benefits of using this tube extend to overall truck performance and longevity, as maintaining clean oil is crucial for engine health.

Installation and Compatibility

Proper installation of the Tur Oil Drain Tube is essential for its effective function. Guidelines for installation should be followed to ensure the tube is securely and correctly positioned within the engine system. Compatibility with various Cummins engine models, as well as other relevant truck makes and models, is an important consideration. Ensuring a secure and effective installation is crucial for the tube’s performance and the engine’s maintenance.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to keep the Tur Oil Drain Tube in optimal condition. This includes periodic inspections for signs of wear or damage and addressing any issues promptly to prevent further complications. Common problems that may arise with oil drain tubes can often be resolved through straightforward troubleshooting steps, emphasizing the importance of routine checks and replacements as part of engine maintenance.

Safety Considerations

When working with the Tur Oil Drain Tube, especially during oil changes, adhering to safety practices is paramount. This includes following manufacturer guidelines and safety protocols to prevent accidents and ensure personal safety. Proper handling and disposal of used oil are also important considerations, highlighting the need for caution and awareness during maintenance procedures.

Environmental Impact

The use of efficient oil drainage systems like the Tur Oil Drain Tube contributes to environmental protection by reducing oil spillage and contamination during oil changes. Proper maintenance and the use of such systems play a role in minimizing the environmental impact of heavy-duty truck operations, underscoring the importance of responsible maintenance practices.

Cummins: A Brief Overview

Cummins Inc. is a leader in the diesel engine and technology market, with a rich history of innovation and a diverse product range. The company’s commitment to quality and reliability has established it as a trusted name in the commercial truck industry. Cummins’ role in providing solutions for engine efficiency, durability, and performance is evident in its wide array of products, including the Tur Oil Drain Tube, which exemplifies the company’s dedication to excellence in diesel technology.

Compatibility with Cummins Engines

The Tur Oil Drain Tube, part number 2899498, is designed to be compatible with various Cummins engines, including the ISX12 G and CM2180 EJ engines. This compatibility ensures that the turbocharger’s oil management system operates smoothly, maintaining the engines’ performance and reliability, especially in demanding applications where efficient oil drainage is vital.

Role in Turbocharger Plumbing

The Tur Oil Drain Tube plays a significant role in the turbocharger plumbing system by facilitating the efficient management of oil flow within the turbocharger assembly. It connects the turbocharger to the engine’s oil supply and return lines, ensuring that the turbocharger receives the necessary lubrication for its bearings and other moving parts. This tube also provides a dedicated pathway for oil to drain back from the turbocharger to the engine’s oil sump, maintaining optimal oil levels and preventing oil starvation, which can lead to turbocharger failure. Additionally, it helps in regulating oil pressure within the turbocharger, contributing to stable operation and prolonged component life.

Conclusion

The Tur Oil Drain Tube, part number 2899498, is a vital component in the maintenance and operation of heavy-duty trucks. Its role in facilitating efficient oil drainage, ensuring engine health, and contributing to environmental protection underscores its importance in the commercial truck industry. Proper installation, maintenance, and understanding of its function within the turbocharger plumbing system are essential for maximizing its benefits and ensuring the longevity and performance of heavy-duty engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.