This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2880512 Inlet Catalyst Module is a component designed for use in the emissions control system of commercial trucks. Its purpose is to help reduce harmful emissions produced by diesel engines, contributing to environmental compliance and improved air quality 1.

Basic Concepts of Inlet Catalyst Modules

An Inlet Catalyst Module is a device that operates within the emissions control system of a vehicle. It works by catalyzing the conversion of harmful exhaust gases into less harmful substances before they are released into the atmosphere. This process is significant for reducing the environmental impact of diesel engines 2.

Purpose and Function

This Cummins part plays a role in the operation of a truck by facilitating the reduction of nitrogen oxides (NOx) and other pollutants in the exhaust stream. It contributes to emissions reduction and helps ensure compliance with environmental regulations, supporting sustainable operation of commercial fleets 3.

Key Features

The Cummins 2880512 Inlet Catalyst Module is characterized by its robust design and the use of advanced materials that enhance its performance and durability. Technological advancements incorporated into this module improve its efficiency in catalyzing exhaust gases, ensuring reliable operation under varying conditions.

Benefits

The advantages provided by the Cummins 2880512 Inlet Catalyst Module include improved engine efficiency through optimized emissions control, reduced emissions that contribute to environmental preservation, and potential cost savings for fleet operators due to enhanced engine performance and compliance with emissions standards.

Installation and Integration

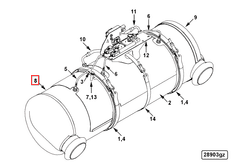

Proper installation and integration of the Cummins 2880512 Inlet Catalyst Module into the truck’s emissions system require adherence to manufacturer guidelines. This process may involve specific preparations or considerations to ensure compatibility and effective operation within the existing system.

Maintenance and Care

Routine maintenance and care of the Cummins 2880512 Inlet Catalyst Module are recommended to ensure optimal performance and longevity. This includes regular inspection intervals and cleaning procedures to remove any buildup that could affect its efficiency.

Troubleshooting Common Issues

Common problems associated with the Cummins 2880512 Inlet Catalyst Module may include reduced efficiency or failure to meet emissions standards. Troubleshooting steps and solutions can involve inspecting for physical damage, ensuring proper installation, and addressing any issues with the module’s integration into the emissions system.

Environmental Impact

The use of the Cummins 2880512 Inlet Catalyst Module results in environmental benefits by reducing pollutants emitted by commercial trucks. Its contribution to cleaner air quality is a significant aspect of its role in the emissions control system.

Cummins Overview

Cummins Inc. is a company with a history of innovation and expertise in diesel engine technology. Its commitment to sustainability and environmental responsibility is evident in the development of components like the 2880512 Inlet Catalyst Module, designed to meet the demands of the commercial truck industry while promoting cleaner operations.

Role of Part 2880512 Inlet Catalyst Module in Aftertreatment Systems

The 2880512 Inlet Catalyst Module is a component within the aftertreatment system of modern engines. Its primary function is to facilitate the initial stages of exhaust gas treatment before the gases enter further downstream components.

When exhaust gases exit the engine, they pass through the Inlet Catalyst Module where preliminary catalytic reactions occur. This module is typically positioned upstream of other aftertreatment devices such as Diesel Particulate Filters (DPFs), Selective Catalytic Reduction (SCR) systems, and additional catalyst modules.

The Inlet Catalyst Module helps in reducing the concentration of harmful pollutants such as Nitrogen Oxides (NOx) and Hydrocarbons (HC) by promoting oxidation reactions. This preliminary treatment enhances the efficiency of subsequent aftertreatment components, ensuring that the exhaust gases meet stringent emission standards before being released into the atmosphere.

Conclusion

In summary, the Cummins 2880512 Inlet Catalyst Module plays a significant role in the aftertreatment process by initiating the reduction of pollutants, thereby supporting the overall effectiveness of the emission control system. Its robust design, advanced materials, and technological advancements contribute to its efficiency and reliability in catalyzing exhaust gases. The module’s benefits include improved engine efficiency, reduced emissions, and potential cost savings for fleet operators. Proper installation, maintenance, and troubleshooting are essential for ensuring optimal performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.