This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2880505 Inlet Catalyst Module is a component designed for use in heavy-duty trucks. Its purpose is to enhance the efficiency of the exhaust system and contribute to emission control. By integrating this module, trucks can achieve better performance in terms of emissions, potentially leading to improved environmental compliance and operational efficiency.

Function and Operation

The Inlet Catalyst Module operates within the exhaust system of heavy-duty trucks, playing a role in reducing harmful emissions. It utilizes a series of chemical processes to convert exhaust gases into less harmful substances before they are released into the atmosphere. The module contains a catalyst that facilitates these chemical reactions, ensuring that pollutants such as nitrogen oxides (NOx) and particulate matter are minimized 1.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the high temperatures and pressures typical of heavy-duty truck exhaust systems. The module incorporates advanced technological features, such as precision-engineered catalyst substrates, which enhance its effectiveness in emission reduction.

Benefits

Using the Inlet Catalyst Module offers several advantages. It contributes to improved emission control, helping trucks meet stringent environmental regulations. Additionally, the module may lead to potential increases in fuel efficiency, as optimized emission control can sometimes result in more efficient engine operation. Compliance with environmental regulations is another significant benefit, ensuring that trucks remain operational in regions with strict emission standards 2.

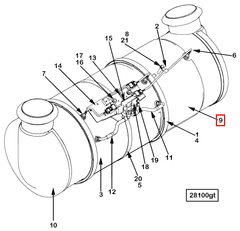

Installation and Integration

Proper installation of the Inlet Catalyst Module requires adherence to specific guidelines to ensure optimal performance. This may involve modifications to the truck’s exhaust system to accommodate the module. Integration with other emission control components is crucial for achieving the desired emission reduction outcomes. Detailed instructions should be followed to ensure a seamless installation process.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and efficiency of the Inlet Catalyst Module. This includes periodic inspections and cleaning to remove any buildup that may affect performance. Common issues, such as reduced efficiency or catalyst damage, can often be addressed through troubleshooting steps that involve checking for proper installation, ensuring the exhaust system is free of obstructions, and verifying that all connections are secure.

Regulatory Compliance

The Cummins 2880505 Inlet Catalyst Module assists trucks in meeting various emission standards and regulations. It plays a role in helping vehicles comply with environmental laws by reducing the output of harmful pollutants. An overview of relevant regulations and the module’s contribution to compliance underscores its importance in the context of environmental protection 3.

Performance Impact

The incorporation of the Inlet Catalyst Module can affect the overall performance of the truck. It may lead to changes in engine output and fuel consumption, as the module optimizes the exhaust system’s efficiency. Driving characteristics may also be influenced, with potential improvements in engine responsiveness and overall vehicle performance.

Environmental Impact

The environmental benefits of the Cummins 2880505 Inlet Catalyst Module are significant. By reducing emissions of pollutants, it contributes to improved air quality. The module’s role in minimizing the release of harmful substances into the atmosphere highlights its positive impact on the environment.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its commitment to innovation and quality in manufacturing automotive components. With a rich history of developing reliable and efficient solutions for heavy-duty applications, Cummins continues to lead in the production of advanced emission control technologies.

Role of Part 2880505 Inlet Catalyst Module in Aftertreatment Systems

The 2880505 Inlet Catalyst Module is an integral component within the aftertreatment system of modern engines. Its primary function is to facilitate the initial stages of exhaust gas treatment before the gases enter the main aftertreatment components.

Integration with Aftertreatment Device

When exhaust gases exit the engine, they first encounter the Inlet Catalyst Module. This module is strategically positioned to ensure that the gases are pre-treated, reducing the load on downstream components such as the Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), and Selective Catalytic Reduction (SCR) system.

Function in the System

- Pre-Catalytic Conversion: The Inlet Catalyst Module initiates the conversion of harmful pollutants such as Nitrogen Oxides (NOx) and Hydrocarbons (HC) into less harmful substances. This pre-treatment is essential for optimizing the efficiency of the subsequent aftertreatment components.

- Temperature Management: By beginning the exothermic reactions early in the exhaust stream, the Inlet Catalyst Module helps in raising the temperature of the exhaust gases. This is particularly beneficial for the DOC and SCR, which operate more effectively at higher temperatures.

- Reduction of Backpressure: Efficiently managing the flow of exhaust gases, the Inlet Catalyst Module helps in minimizing backpressure within the system. This ensures that the engine operates smoothly without unnecessary strain.

- Enhanced Overall Efficiency: The pre-treatment of exhaust gases by the Inlet Catalyst Module contributes to the overall efficiency of the aftertreatment system. It ensures that the subsequent components can operate within their optimal parameters, leading to better emission control and engine performance.

Conclusion

In summary, the Cummins 2880505 Inlet Catalyst Module plays a significant role in the aftertreatment system by preparing the exhaust gases for further processing, enhancing the efficiency and effectiveness of the entire system.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.