This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2874269 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to its overall operation and performance.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals within a vehicle. It consists of multiple wires bundled together, often secured with ties or conduits, and includes various connectors that link to different parts of the vehicle’s electrical system. The primary function of a wiring harness is to organize and protect the wires, ensuring they are safely routed and can withstand the vehicle’s operating conditions 1.

Purpose of the 2874269 Wiring Harness

This Cummins part is specifically engineered to integrate with the electrical systems of commercial trucks. It plays a role in connecting the truck’s engine control module (ECM) with sensors, actuators, and other electrical components. This integration allows for the efficient management of engine functions, including fuel injection, emissions control, and engine monitoring. The harness also supports the operation of auxiliary systems, such as lighting and climate control, by providing a reliable pathway for electrical signals and power.

Key Features

The 2874269 Wiring Harness is characterized by its robust design and the use of high-quality materials. It is constructed with durable wires and connectors that are resistant to corrosion, abrasion, and temperature extremes. The harness is also designed to be flexible, allowing it to fit within the confined spaces of a truck’s engine compartment. Additionally, it features protective coatings and shielding to enhance its performance and longevity in demanding environments 2.

Benefits

The use of the 2874269 Wiring Harness offers several advantages in truck operations. It contributes to improved efficiency by ensuring that electrical signals and power are transmitted with minimal loss. This results in more reliable engine performance and better fuel efficiency. The harness also enhances safety by providing a secure and organized pathway for electrical connections, reducing the risk of short circuits and electrical fires. Furthermore, its durable construction ensures long-term reliability, minimizing the need for frequent repairs or replacements.

Installation and Integration

Proper installation of the 2874269 Wiring Harness is crucial for its effective operation. It should be carefully routed to avoid contact with moving parts or sharp edges that could damage the wires. Secure mounting and proper connection to the ECM and other components are necessary to ensure a stable and reliable electrical system. Integration with existing wiring should be done with attention to detail, ensuring that all connections are secure and that the harness is compatible with the truck’s electrical system.

Troubleshooting and Maintenance

Regular inspection and maintenance of the 2874269 Wiring Harness are important to ensure its continued performance. Common issues may include worn or damaged wires, loose connections, or corrosion on connectors. These can often be identified through visual inspection and testing of electrical systems. Maintenance practices include cleaning connectors, securing loose wires, and replacing damaged sections of the harness. Adhering to a routine maintenance schedule can help prevent more serious electrical problems and extend the life of the wiring harness.

Safety Considerations

When working with the 2874269 Wiring Harness, it is important to observe safety protocols to prevent accidents. This includes disconnecting the battery before beginning any work on the electrical system to avoid the risk of electrical shock. Additionally, using appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses, can help protect against injuries. Following manufacturer guidelines and industry standards for electrical work is also crucial to ensure safety and compliance.

Environmental Impact

The production, use, and disposal of the 2874269 Wiring Harness have environmental implications. Efforts to minimize its ecological footprint include the use of recyclable materials in its construction and the implementation of recycling programs for old or damaged harnesses. Additionally, designing the harness for longevity and reliability reduces the need for frequent replacements, further lowering its environmental impact. Cummins is committed to reducing the environmental impact of its products through continuous improvement and innovation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leader in the automotive industry, known for its commitment to innovation, quality, and customer satisfaction. The company offers a wide range of products and services designed to meet the needs of various industries, including commercial trucking, construction, agriculture, and power generation. Cummins’ dedication to excellence and sustainability is reflected in its product offerings and corporate practices.

Compatibility with Engine Models

The 2874269 Wiring Harness is designed to integrate seamlessly with several engine models, ensuring reliable electrical connectivity and performance. This wiring harness is compatible with the following engine series:

- ISZ13 CM2150 Z105

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

These engines, while distinct in their specific configurations, share common electrical architecture that allows the 2874269 wiring harness to fit effectively. The harness is engineered to handle the electrical demands of these engines, providing a robust connection between various engine components and the vehicle’s electrical system.

By ensuring compatibility across these models, the 2874269 wiring harness offers a versatile solution for maintaining the integrity of the engine’s electrical system, facilitating efficient operation and reducing the risk of electrical failures.

Role of Part 2874269 Wiring Harness in Engine Systems

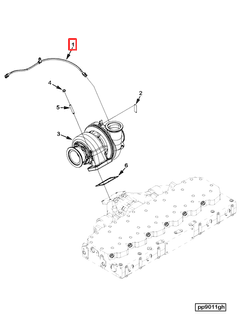

The part 2874269 wiring harness is an integral component in the electrical system of engine setups, particularly when integrated with a turbocharger. Its primary function is to facilitate the electrical connections required for the turbocharger to operate efficiently.

Integration with Turbocharger

When a turbocharger is installed, it requires a reliable electrical supply to power its actuators and sensors. The wiring harness ensures that all necessary connections are made securely and efficiently. This includes:

- Actuator Power Supply: The wiring harness provides the electrical power needed for the turbocharger’s actuator, which controls the turbine’s speed and, consequently, the amount of boost delivered to the engine.

- Sensor Connections: Various sensors, such as the boost pressure sensor and turbine speed sensor, are connected via the wiring harness. These sensors provide critical data to the engine control unit (ECU), allowing it to make real-time adjustments for optimal performance.

- Grounding: Proper grounding is essential for the turbocharger’s electrical components. The wiring harness includes grounding wires that ensure a stable electrical environment, reducing the risk of interference and ensuring accurate sensor readings.

Enhanced Performance and Reliability

By standardizing the electrical connections, the wiring harness enhances the overall reliability of the turbocharger system. It reduces the likelihood of loose connections, which can lead to intermittent issues or complete failure of the turbocharger. Additionally, the harness is designed to withstand the high temperatures and vibrations typical in engine compartments, ensuring long-term durability.

Simplified Installation and Maintenance

The use of a dedicated wiring harness like part 2874269 simplifies the installation process of the turbocharger. It comes pre-assembled with the correct gauge wires and connectors, reducing the time and skill required for installation. Moreover, it makes maintenance more straightforward, as technicians can quickly trace and diagnose electrical issues within the turbocharger system.

Conclusion

The Cummins 2874269 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring efficient and reliable operation of the engine and auxiliary systems. Its robust design, compatibility with various engine models, and integration with turbochargers make it a versatile and essential part for maintaining the performance and safety of commercial vehicles. Regular maintenance and adherence to safety protocols are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.