This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 2871897 After Treatment Device is a component designed to enhance the emissions control system of commercial trucks. Its role is significant in the context of commercial truck operations, where stringent emissions regulations are in place. This device contributes to reducing the environmental impact of heavy-duty trucks by managing exhaust emissions more effectively.

Basic Concepts of After Treatment Devices

After treatment devices are systems installed in the exhaust pathways of vehicles to reduce the levels of harmful emissions released into the atmosphere. These devices work by filtering, converting, or otherwise neutralizing pollutants before they exit the exhaust system. In heavy-duty trucks, after treatment devices are integrated into the exhaust system to ensure that the emissions produced meet regulatory standards 1.

Purpose of the Cummins 2871897 After Treatment Device

This Cummins part is specifically engineered to play a role in the emissions control system of trucks. It functions by processing exhaust gases to reduce the levels of pollutants such as nitrogen oxides (NOx) and particulate matter (PM). This device is part of a comprehensive system that helps trucks comply with emissions regulations while maintaining performance 2.

Key Features

The Cummins 2871897 After Treatment Device incorporates several key features that enhance its performance. Its design is optimized for efficient emissions reduction, utilizing advanced materials that withstand the harsh conditions of the exhaust system. Technological innovations within the device, such as improved catalyst formulations and structural enhancements, contribute to its effectiveness in reducing emissions 3.

Benefits

The advantages of the Cummins 2871897 After Treatment Device include improved compliance with emissions regulations, which is crucial for commercial truck operators. Additionally, the device may contribute to potential fuel efficiency gains by optimizing the exhaust flow and reducing backpressure. Its durable construction ensures longevity, providing reliable performance over the vehicle’s operational life.

Installation and Integration

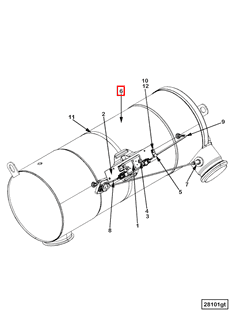

Installing the Cummins 2871897 After Treatment Device into a truck’s exhaust system requires careful consideration of the existing exhaust layout and the specific requirements of the truck model. Proper integration ensures that the device functions effectively within the emissions control system, contributing to the overall performance and compliance of the vehicle.

Operational Efficiency

The Cummins 2871897 After Treatment Device contributes to the overall efficiency of the truck by ensuring that the exhaust system operates within optimal parameters. Its design and function help maintain engine performance while reducing the environmental impact of the truck’s operations. Efficient emissions control can also lead to improved fuel consumption, benefiting both the operator and the environment.

Maintenance and Troubleshooting

Maintaining the Cummins 2871897 After Treatment Device involves regular inspections and adherence to the manufacturer’s guidelines to ensure optimal performance. Common issues may include catalyst degradation or blockages within the device. Troubleshooting tips include monitoring the device’s performance through diagnostic tools and addressing any signs of reduced efficiency promptly.

Environmental Impact

The use of the Cummins 2871897 After Treatment Device results in significant environmental benefits by reducing the levels of harmful emissions released by trucks. Compliance with environmental regulations is achieved through the effective operation of this device, contributing to cleaner air and reduced environmental impact from commercial truck operations.

Technological Advancements

The Cummins 2871897 After Treatment Device incorporates several technological advancements to enhance its performance. These include sensor integration for real-time monitoring of emissions, advanced monitoring capabilities to ensure optimal operation, and software controls that adjust the device’s function based on driving conditions and emissions requirements.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong commitment to innovation and sustainability, Cummins plays a significant role in the automotive industry by providing advanced engine and emissions technology solutions that meet the evolving needs of commercial vehicle operators and environmental regulations.

Role of Part 2871897 After Treatment Device in Engine Systems

The After Treatment Device, identified as part 2871897, is integral to the operation of modern engine systems, particularly in ensuring compliance with stringent emissions regulations. This component works in concert with several other engine components to reduce harmful emissions and improve overall engine efficiency.

Integration with the Exhaust System

The After Treatment Device is positioned downstream of the engine’s exhaust manifold. Its primary function is to treat the exhaust gases before they are released into the atmosphere. It interfaces directly with the exhaust gas recirculation (EGR) system, which routes a portion of the exhaust gas back into the intake manifold to reduce nitrogen oxides (NOx) formation.

Interaction with the Diesel Particulate Filter (DPF)

In diesel engine systems, the After Treatment Device often includes or works alongside a Diesel Particulate Filter (DPF). The DPF captures particulate matter from the exhaust gases, and the After Treatment Device helps in the regeneration process by oxidizing trapped particles, ensuring the DPF maintains optimal performance over time.

Coordination with the Selective Catalytic Reduction (SCR) System

For engines equipped with a Selective Catalytic Reduction (SCR) system, the After Treatment Device plays a significant role in the reduction of NOx emissions. It works in tandem with the SCR system by ensuring that the exhaust gases are at the appropriate temperature and composition for the SCR catalyst to effectively convert NOx into harmless nitrogen and water vapor.

Synergy with the Turbocharger

The turbocharger, which increases the engine’s power output by forcing extra air into the combustion chamber, also benefits from the presence of the After Treatment Device. By ensuring that the exhaust gases are clean and at the right temperature, the After Treatment Device helps maintain the turbocharger’s efficiency and longevity.

Contribution to the Engine Control Unit (ECU)

The After Treatment Device communicates with the Engine Control Unit (ECU) through various sensors that monitor exhaust gas temperature, pressure, and composition. This data allows the ECU to make real-time adjustments to the engine’s operation, optimizing performance while minimizing emissions.

Enhancement of the Overall Engine Performance

By effectively treating exhaust gases, the After Treatment Device contributes to the engine’s overall performance. It helps maintain the engine’s efficiency by ensuring that the exhaust system operates within designed parameters, reducing backpressure and allowing for smoother engine operation.

Conclusion

In summary, the Cummins 2871897 After Treatment Device is a key component in modern engine systems, working in harmony with the exhaust system, DPF, SCR system, turbocharger, and ECU to ensure efficient and clean engine operation. Its role in reducing emissions and enhancing engine performance underscores its importance in the automotive industry, particularly for commercial truck operations.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.