This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 214927 Crankshaft Pulley is a critical component designed for use in commercial trucks. It facilitates the transfer of rotational force from the crankshaft to various engine accessories, playing a significant role in the engine’s operation. Understanding its function and importance can aid in maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a toothed wheel attached to the front of an engine’s crankshaft. Its primary function is to drive engine accessories such as the alternator, power steering pump, and air conditioning compressor through a belt or chain 1. The pulley helps maintain the timing and synchronization of these components, ensuring they operate efficiently and effectively.

Role of the 214927 Crankshaft Pulley in Truck Operation

The 214927 Crankshaft Pulley connects the crankshaft to the engine’s accessory drive system, allowing for the transfer of power needed to operate various engine components. Its design ensures smooth operation and reduces vibrations, contributing to the overall stability and performance of the truck’s engine 2.

Key Features of the 214927 Crankshaft Pulley

This Cummins part is constructed with high-quality materials to ensure durability and reliability. It features a robust design that includes a dampening element to absorb vibrations and a precision-machined surface for optimal belt grip. The pulley is engineered to meet the demanding requirements of commercial truck engines, providing long-lasting performance 3.

Benefits of Using the 214927 Crankshaft Pulley

Using this part offers several advantages. It contributes to improved engine performance by ensuring efficient power transfer to engine accessories. The pulley’s design enhances durability, reducing the likelihood of failure under high stress conditions. Additionally, it promotes efficiency by minimizing energy loss through its smooth operation and vibration dampening features.

Installation and Compatibility

Proper installation of the 214927 Crankshaft Pulley is important for ensuring optimal performance and longevity. It is designed to fit specific truck models, and adherence to manufacturer guidelines during installation is recommended. This includes ensuring proper alignment and tensioning of the accessory drive belt to prevent slippage and wear.

Maintenance and Troubleshooting

Regular maintenance of the 214927 Crankshaft Pulley involves inspecting for signs of wear, such as cracks or excessive play, and ensuring the accessory drive belt is in good condition. Common issues may include belt slippage or pulley misalignment, which can be addressed by adjusting tension or realigning components as necessary. Following a routine maintenance schedule can help prevent more serious problems.

Performance Enhancements

The 214927 Crankshaft Pulley contributes to overall engine performance by providing a stable and efficient means of powering engine accessories. This can lead to improvements in torque output, power delivery, and fuel efficiency, as the engine operates more smoothly and with reduced vibrations.

Safety Considerations

When handling and installing the 214927 Crankshaft Pulley, it is important to follow safety precautions. This includes ensuring the engine is off and cooled down before beginning work, using appropriate tools and equipment, and adhering to all manufacturer recommendations. Operational safety measures involve regular inspections and maintenance to ensure the pulley remains in good working condition.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance components for the automotive and heavy-duty truck industries. Their products are known for durability, efficiency, and cutting-edge technology.

Compatibility of Cummins Crankshaft Pulley Part 214927

The Cummins Crankshaft Pulley part number 214927 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s operation, as it interfaces with the crankshaft to drive the accessory belt, which in turn powers essential components such as the alternator, water pump, and air conditioning compressor.

N14 MECHANICAL Engines

The N14 MECHANICAL engine series is one of the prominent applications for the Cummins Crankshaft Pulley part number 214927. This engine is renowned for its robust construction and high performance, making it a preferred choice in various heavy-duty applications. The compatibility of part 214927 with the N14 MECHANICAL engine ensures that the accessory belt operates efficiently, maintaining the necessary functions of the engine’s ancillary systems.

The integration of this crankshaft pulley with the N14 MECHANICAL engine is critical for maintaining the engine’s overall balance and smooth operation. The precise fit and quality of the part ensure that it can withstand the rigorous demands of heavy-duty operations, providing long-lasting durability and performance.

Understanding the Integration of Part 214927 Crankshaft Pulley in Engine Systems

The crankshaft pulley, identified as part 214927, is an essential component in the orchestration of various engine systems. Its primary function is to transmit rotational force from the crankshaft to other auxiliary components, ensuring the seamless operation of the engine.

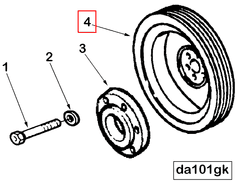

Interaction with the Damper

The crankshaft pulley works in conjunction with the damper, which is designed to absorb vibrations generated by the engine. This interaction is vital for maintaining a smooth operation, as the damper mitigates the torsional vibrations that could otherwise lead to mechanical wear and reduced efficiency. The pulley’s design allows it to effectively transfer power while accommodating the damper’s role in vibration management.

Role in the Vibration Damping System

In more complex setups, the crankshaft pulley is part of a vibration damping system that includes components like the damper/flange/fpto and damper/pulley/fpt0. These systems are engineered to handle higher levels of vibration and torsional stress. The pulley’s precise fit and balance are key to ensuring that these systems function as intended, providing a stable platform for power transmission despite the dynamic forces at play.

Integration with the EBM System

In engines equipped with an Electronically Controlled Brake Module (EBM), the crankshaft pulley interfaces with both the EBM damper and EBM pulley. This integration is designed to enhance the control over engine braking and vibration management. The pulley’s role here is to facilitate the transfer of power in a manner that complements the EBM’s functions, ensuring that engine braking is applied smoothly and efficiently.

Connection to the Crankshaft

At the heart of its function, the crankshaft pulley is directly connected to the crankshaft. This connection is fundamental as it allows the pulley to convert the linear motion of the pistons into rotational motion, which is then transmitted to other engine components. The efficiency of this conversion is dependent on the pulley’s design and its precise alignment with the crankshaft.

Conclusion

In summary, the 214927 Crankshaft Pulley is a pivotal component in the engine’s power transmission system. Its integration with dampers, vibration damping systems, EBM components, and the crankshaft itself underscores its importance in ensuring the engine operates smoothly and efficiently.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.