This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

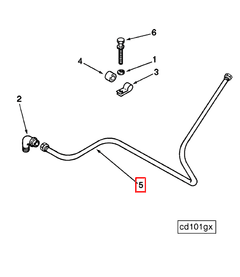

The Compressor Water Outlet Tube, identified by Part #211772, is a component manufactured by Cummins. This part is integral to the cooling systems of heavy-duty trucks, facilitating the efficient management of coolant flow to maintain optimal engine temperatures 1.

Function and Operation

The Compressor Water Outlet Tube operates by directing coolant from the compressor to other parts of the engine cooling system. It ensures that coolant is evenly distributed, which helps in maintaining consistent temperatures across the engine components. This Cummins part connects to the compressor and routes the coolant to the next stage in the cooling process, ensuring that the compressor itself and other engine parts remain within safe operating temperatures 2.

Purpose of the Compressor Water Outlet Tube

The primary role of the Compressor Water Outlet Tube in a truck’s operation is to manage the flow of coolant from the compressor. By doing so, it contributes to the overall efficiency of the engine cooling system. This management of coolant flow is vital for preventing overheating, which can lead to engine damage and reduced performance 3.

Key Features

The Compressor Water Outlet Tube is constructed from durable materials that can withstand the high pressures and temperatures of engine coolant systems. Its design includes precise fittings and connections that ensure a secure attachment to the compressor and other system components. Additionally, the tube may feature reinforced sections to enhance durability and prevent leaks.

Benefits

The advantages of the Compressor Water Outlet Tube include improved coolant circulation, which leads to better temperature regulation within the engine. This enhanced circulation contributes to the protection of engine components from overheating and potential damage. Furthermore, the efficient design of the tube supports the overall efficiency of the cooling system, which can lead to improved engine performance and longevity.

Installation Considerations

Proper installation of the Compressor Water Outlet Tube involves ensuring that all connections are secure and that the tube is correctly aligned with the compressor and other system components. Tools required may include wrenches for tightening connections and possibly a torque wrench to ensure that fittings are tightened to the manufacturer’s specifications. It is also important to verify that there are no obstructions or kinks in the tube that could impede coolant flow.

Common Issues and Troubleshooting

Typical problems with the Compressor Water Outlet Tube can include leaks at connection points or blockages within the tube. Troubleshooting steps may involve inspecting all connections for tightness and signs of wear or damage. If a blockage is suspected, the tube may need to be flushed or replaced to restore proper coolant flow.

Maintenance Tips

Routine maintenance of the Compressor Water Outlet Tube includes regular inspections for signs of wear, corrosion, or leaks. Cleaning the exterior of the tube and ensuring that all connections remain tight can help prevent issues. It is also beneficial to follow the manufacturer’s recommendations for coolant changes and system flushes to maintain the efficiency of the cooling system.

Cummins Overview

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its high-quality components and innovative solutions. With a long history of providing reliable and efficient parts, Cummins continues to be a leader in the field, committed to enhancing the performance and durability of vehicles through its products.

Understanding the Integration of Part 211772 Compressor Water Outlet Tube in Engine Systems

The part 211772 Compressor Water Outlet Tube is a component in the efficient operation of various engine systems. Its primary function is to facilitate the discharge of water from the compressor, ensuring that the system remains free from moisture accumulation, which can lead to corrosion and reduced efficiency.

Interaction with Accessory Drive and Mounting Components

When integrated with the accessory drive and mounting (acc drive & mtg) components, the Compressor Water Outlet Tube works in conjunction to maintain the structural integrity and operational efficiency of the accessory drive system. The acc drive mtg ensures that all accessory components, including the compressor and its associated tubes, are securely fastened to the engine. This secure mounting is vital for the stable operation of the Compressor Water Outlet Tube, allowing it to effectively channel water away from the compressor without any risk of detachment or misalignment.

Synergy with Air Compressor Tube

The Compressor Water Outlet Tube is directly connected to the air compressor tube, forming a critical pathway for the expulsion of water that has been separated from the compressed air. This connection ensures that any moisture collected within the compressor is efficiently removed, preventing potential damage to the compressor and maintaining the quality of the compressed air output. The seamless integration between these components is essential for the overall performance and longevity of the compressor system.

Coordination with Water Drain and Water Drain Tube

In conjunction with the water drain and water drain tube, the Compressor Water Outlet Tube plays a pivotal role in the comprehensive water management system of the engine. The water drain facilitates the collection of moisture from various parts of the engine, while the water drain tube provides a dedicated pathway for this water to be expelled from the system. The Compressor Water Outlet Tube, by connecting to this network, ensures that water from the compressor is efficiently routed to the drain, contributing to a dry and efficient engine environment.

Overall Contribution to Engine Efficiency

The effective integration of the Compressor Water Outlet Tube with these components underscores its importance in maintaining engine efficiency. By ensuring that moisture is promptly and effectively removed from the compressor, this part helps in preventing corrosion, maintaining compressor performance, and ensuring the delivery of dry, high-quality compressed air. This, in turn, contributes to the overall reliability and efficiency of the engine system.

Conclusion

The 211772 Compressor Water Outlet Tube is a vital component in the cooling systems of heavy-duty trucks, ensuring efficient coolant flow and temperature regulation. Its integration with other engine components enhances the overall performance and longevity of the engine system. Proper installation, maintenance, and understanding of its function are key to maximizing its benefits and ensuring the reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.