This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Pump Gear 204832 is a component designed by Cummins to facilitate the efficient operation of heavy-duty trucks. This gear is integral to the oil pump system, ensuring that engine components receive the necessary lubrication to function smoothly and maintain longevity. Its role in the lubrication process underscores its significance in the overall performance and reliability of heavy-duty engines 1.

Function and Operation

The Lubricating Oil Pump Gear 204832 operates within the oil pump system by driving the pump mechanism that circulates oil throughout the engine. It plays a role in maintaining consistent oil pressure, which is vital for the proper lubrication of moving parts such as bearings, pistons, and camshafts. By ensuring a steady flow of oil, this gear helps to reduce friction and wear, contributing to the engine’s efficiency and durability 2.

Key Features

The Lubricating Oil Pump Gear 204832 is constructed with precision to meet the demanding requirements of heavy-duty applications. It is made from high-quality materials that offer resistance to wear and corrosion. The gear tooth profile is designed to provide optimal meshing with its counterpart, ensuring smooth operation and minimizing the risk of gear failure. Additionally, the gear may feature unique characteristics such as a specific hardness or coating that enhances its performance and longevity in harsh operating conditions 3.

Benefits

The use of the Lubricating Oil Pump Gear 204832 offers several advantages. It contributes to improved engine efficiency by ensuring that all moving parts are adequately lubricated, which reduces friction and heat generation. This can lead to enhanced overall performance of the lubrication system and potentially extend the service life of the engine. Furthermore, the gear’s design helps to minimize wear on engine components, which can result in fewer maintenance requirements and lower operating costs over time.

Installation and Compatibility

When installing the Lubricating Oil Pump Gear 204832, it is important to follow the manufacturer’s guidelines to ensure proper fitment and function. This gear is compatible with specific Cummins engines, and it is designed to meet the precise requirements of these applications. During installation, attention should be paid to any specific requirements or considerations provided by Cummins to ensure the gear is correctly positioned and secured.

Maintenance and Troubleshooting

To maintain the Lubricating Oil Pump Gear 204832 and ensure optimal performance, regular inspection, cleaning, and lubrication are recommended. This includes checking for signs of wear or damage and ensuring that the gear mesh is correct. In the event of common issues such as unusual noise or a drop in oil pressure, troubleshooting may involve inspecting the gear for damage, ensuring proper alignment, and verifying that the lubrication system is functioning correctly. Recommended solutions will depend on the specific issue identified during maintenance checks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the realm of heavy-duty truck components. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the rigorous demands of commercial and industrial applications.

Compatibility of Lubricating Oil Pump Gear (Part 204832)

The Cummins Lubricating Oil Pump Gear, identified by part number 204832, is designed to ensure the proper functioning of the oil system in various engine models. This gear is engineered to work seamlessly with the following Cummins engine models:

- G855: Ensures optimal oil flow and pressure, which is crucial for maintaining engine health and performance.

- N14 CELECT and N14 MECHANICAL: Provides consistent lubrication to engine components, which is essential for reducing wear and extending engine life.

- NH/NT 855: Ensures that these engines receive the necessary lubrication, helping to maintain operational efficiency and reliability.

The 204832 gear is crafted to meet the stringent demands of these engines, ensuring that they operate smoothly and efficiently. Its compatibility across these models highlights its versatility and the importance of using the correct components for optimal engine performance.

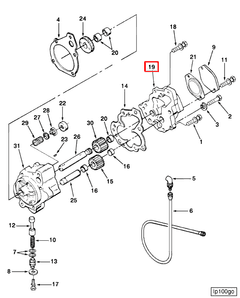

Role of Part 204832 Lubricating Oil Pump Gear in Engine Systems

The Part 204832 Lubricating Oil Pump Gear is an integral component within various engine systems, ensuring the efficient circulation of lubricating oil throughout the engine. This gear is specifically designed to work in harmony with the lubricating oil pump, which is a key element in the lubrication system of an engine.

Integration with Lubricating Oil Systems

- Lubricating Oil Pump Kit: The gear is a fundamental part of the lubricating oil pump kit. It engages with the pump’s drive mechanism to create the necessary pressure for oil circulation. This ensures that all moving parts within the engine receive a consistent supply of lubricant, reducing friction and wear.

- Lubricating Oil Filter: In conjunction with the lubricating oil filter, the gear helps maintain clean oil by ensuring a steady flow through the filter media. This is essential for removing contaminants and maintaining the integrity of the lubrication system.

- Lubricating Oil (Top Level Assembly) Pump: When integrated into the top-level assembly pump, the gear contributes to the overall efficiency of the pump. It ensures that oil is delivered at the correct pressure and volume to critical engine components.

Interaction with Engine Components

- Block and Short Block Assemblies: Within the block and short block assemblies, the gear plays a role in maintaining the lubrication of the crankshaft, camshaft, and other internal components. This is vital for the smooth operation and longevity of the engine.

- Cyl Short NTC-400: In engines utilizing the Cyl Short NTC-400 configuration, the gear ensures that the unique lubrication requirements of this setup are met. It helps in delivering oil to the cylinder components efficiently.

- Service Kit & Pump, Lub Oil: When part of a service kit, the gear is often replaced to ensure the pump operates at peak efficiency. This is particularly important during maintenance procedures to prevent lubrication failures.

Auxiliary and Hydraulic Systems

- Pump, Auxiliary: In systems where an auxiliary pump is used, the gear ensures that additional lubrication needs are met, such as for turbochargers or other high-stress components.

- Hydraulic Pump: Although primarily a mechanical component, the gear’s role in the hydraulic pump ensures that hydraulic systems within the engine receive adequate lubrication, contributing to the overall performance and reliability of the engine.

Control and Multi-Unit Systems

- Control and M.U.T.C.: In engines with control and multi-unit throttle control (M.U.T.C.) systems, the gear ensures that the lubrication system operates in sync with these control mechanisms, enhancing engine performance and responsiveness.

- EBM: Pump: In engines where the EBM (Electrically Driven Pump) is used, the gear ensures that the electrically driven lubrication system functions correctly, providing consistent oil pressure even under varying engine loads.

Scavenge Pump Body

The gear also interacts with the scavenge pump body, ensuring that used oil is efficiently returned to the sump, maintaining a closed-loop lubrication system that is essential for engine health.

Conclusion

In summary, the Part 204832 Lubricating Oil Pump Gear is a vital component that ensures the reliable operation of the lubrication system across various engine configurations and components. Its role in maintaining oil pressure and flow is essential for the protection and performance of engine parts.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Pawel Drozdziel, The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects (Routledge, 2023).

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.