191916

Injector Plunger Link

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Injector Plunger Link 191916, manufactured by Cummins, is a critical component in diesel engine systems, particularly within the fuel injection mechanism. Understanding its function and importance is essential for maintaining and optimizing diesel engine performance.

Basic Concepts of Injector Plunger Link

Injector plunger links are vital for the operation of fuel injection systems. They facilitate the precise delivery of fuel into the combustion chamber through mechanical and hydraulic processes. The injector plunger link acts as a connector between the fuel injector and the engine’s fuel system, translating mechanical motion into hydraulic force for fuel injection 1.

Operation of Injector Plunger Link 191916

The Injector Plunger Link 191916 operates through mechanical and hydraulic interactions. It moves in response to the engine’s camshaft, activating the fuel injector. This movement creates pressure within the fuel system, allowing for precise fuel injection into the combustion chamber. The design of this Cummins part ensures efficiency and reliability, contributing to engine performance 2.

Purpose and Role in Truck Operation

In heavy-duty truck engines, the Injector Plunger Link 191916 ensures precise fuel injection into the engine’s cylinders. This contributes to efficient combustion, enhancing engine performance and fuel economy. Maintaining the integrity of the fuel injection process is crucial for the reliability and efficiency of heavy-duty truck engines 3.

Key Features

The Injector Plunger Link 191916 is designed with robust construction to withstand high pressures and temperatures. The materials used are selected for strength and resistance to wear, ensuring long-term reliability. Its design is optimized for efficient fuel delivery, making it effective in heavy-duty applications.

Benefits of Using Injector Plunger Link 191916

Using this part offers several benefits, including improved fuel efficiency due to precise fuel delivery. Enhanced engine performance is another advantage, as reliable fuel injection contributes to smoother and more powerful engine operation. Additionally, the durability and reliability of this Cummins part can lead to reduced maintenance costs and increased uptime for heavy-duty trucks.

Troubleshooting Common Issues

Identifying and troubleshooting issues with the Injector Plunger Link 191916 can help maintain engine performance. Common symptoms of problems with this component include irregular engine operation, reduced fuel efficiency, and difficulty starting the engine. Diagnosing these issues may involve inspecting the injector plunger link for wear or damage, as well as checking the fuel system for leaks or blockages. Addressing these issues promptly can help prevent more serious engine problems.

Maintenance Tips

To ensure the optimal performance and longevity of the Injector Plunger Link 191916, regular maintenance is recommended. This includes routine inspections for wear or damage, cleaning the component to remove buildup, and replacement when necessary. Following manufacturer guidelines for maintenance can help prevent issues and ensure the reliable operation of the fuel injection system.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the diesel engine industry, known for its commitment to quality, innovation, and customer satisfaction. With a diverse product portfolio that includes engines, filtration systems, and power generation equipment, Cummins has established a reputation for excellence. The company’s focus on research and development ensures that its products, including the Injector Plunger Link 191916, meet the high standards required for heavy-duty applications.

Compatibility of Injector Plunger Link 191916

The Injector Plunger Link 191916 is compatible with various Cummins engines, including N14 Mechanical, NH/NT 855, and V28 engines. This compatibility ensures that the injectors function correctly under demanding conditions, maintaining engine performance and reliability.

Role of Injector Plunger Link 191916 in Engine Systems

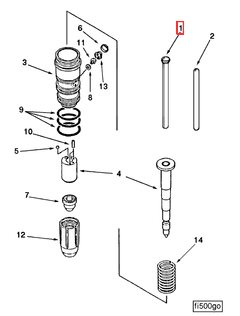

The Injector Plunger Link 191916 is integral to the fuel injection system, interfacing with the injector and cam follower housing to ensure precise movement and timing of the injector plunger. This interaction is essential for the accurate delivery of fuel into the cylinder. The link’s operation is synchronized with the camshaft and gear, dictating the opening and closing cycles of the injector. This synchronization is vital for maintaining engine performance and efficiency. The link also connects to the connecting rod and piston assembly, allowing for the transfer of motion critical for engine operation. In performance parts applications, the link’s durability and precision are paramount. It is a component of the flange type pressure-time delivery injector system, contributing to consistent and controlled fuel injection. When considering injector mounting and the PTD flange, the Injector Plunger Link ensures that the injector is securely held in place while allowing for necessary movement, crucial for the integrity of the injection process and the overall function of the engine.

Conclusion

The Injector Plunger Link 191916 by Cummins is a key element in the fuel injection system, ensuring the engine operates efficiently and effectively. Its role in connecting and synchronizing the movement of the injector with the camshaft and other engine components is fundamental to engine performance.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.