101322

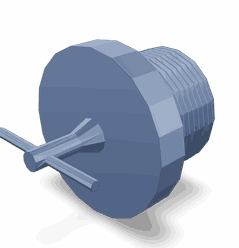

Filler Cap

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 101322 Filler Cap is a component designed for use in the fueling systems of commercial trucks. Its role is to facilitate the secure and efficient transfer of fuel into the vehicle’s tank while preventing spillage and ensuring the integrity of the fuel system.

Purpose of the 101322 Filler Cap

The 101322 Filler Cap functions as an interface between the fuel nozzle and the truck’s fuel tank. It is engineered to create a tight seal that prevents fuel from leaking out during refueling. Additionally, it plays a role in maintaining the pressure within the fuel tank, which is important for the proper operation of the vehicle’s fuel system.

Key Features

The design of the 101322 incorporates several features that enhance its performance and durability. It is constructed from materials that are resistant to the corrosive effects of fuel and the elements. The cap includes a sealing mechanism that ensures a snug fit on the fuel tank opening, and it may feature a venting system to allow air to escape as fuel is added, preventing a vacuum from forming inside the tank.

Benefits

The 101322 offers several advantages. It provides improved fuel security by minimizing the risk of spillage during refueling. Its design allows for ease of use, with a simple twist-to-open mechanism. Furthermore, it is compatible with Cummins fuel systems, ensuring a seamless integration with the truck’s existing components.

Installation Process

To install the 101322, first ensure the fuel tank opening is clean and free of debris. Align the cap with the tank opening and twist it clockwise until it is securely in place. It is important to follow the manufacturer’s guidelines for torque specifications to ensure a proper seal without over-tightening, which could damage the cap or the tank.

Maintenance Tips

Regular maintenance of the 101322 is important for its longevity and optimal performance. This includes periodic cleaning to remove any buildup that could interfere with the seal. Inspect the cap for signs of wear or damage, such as cracks or a compromised seal, and replace it as necessary to maintain the integrity of the fuel system.

Troubleshooting Common Issues

Common issues with the 101322 may include leaks or difficulty in operation. If a leak is detected, check the cap for proper seating and ensure there is no damage to the sealing surfaces. Difficulty in operation could be due to debris in the tank opening or a faulty cap mechanism. In such cases, cleaning the area or replacing the cap may resolve the issue. If problems persist, it may be advisable to seek professional assistance.

Safety Considerations

When handling and maintaining the 101322, it is important to observe safety practices to avoid fuel spills and ensure personal safety. This includes working in a well-ventilated area, wearing appropriate protective gear, and following all safety guidelines provided by the manufacturer.

Environmental Impact

The proper use and maintenance of the 101322 contribute to reducing environmental hazards associated with fuel spills. By preventing leaks and ensuring that fuel is contained within the tank, the cap helps minimize the risk of contamination to soil and water sources.

Cummins Engine Compatibility

The Cummins part number 101322, which is a Filler Cap, is compatible with a variety of Cummins engines. Below is a detailed breakdown of the engines that this filler cap fits:

- 4B3.9 and 6B5.9 Engines: The filler cap 101322 is specifically designed to fit these engines, ensuring a secure seal that prevents contaminants from entering the fuel system.

- B3.9 G, B4.5, B5.9 G, and B6.7 CM2670 B153B, B6.7 CM2670 B164C Engines: The filler cap 101322 is engineered to match the design specifications of these engines, ensuring compatibility and ease of installation.

- C GAS PLUS CM556 and C8.3 G Engines: The filler cap 101322 fits these engines seamlessly, providing a reliable seal that is essential for maintaining optimal engine performance.

- G5.9, G5.9 CM558, G8.3, G8.3 CM558, G855, and GTA8.3 CM558 Engines: The filler cap 101322 is designed to fit these engines, ensuring that the fuel system remains protected from contaminants.

- ISB CM550, ISB CM850, ISBE CM800, ISC CM554, ISL CM554, ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN Engines: The filler cap 101322 is compatible with these engines, providing a secure and reliable seal that is essential for maintaining engine efficiency and longevity.

Role of Part 101322 Filler Cap in Engine Systems

The part 101322 Filler Cap is a component within various engine systems, facilitating the efficient operation and maintenance of these systems. Its primary function is to seal the oil fill tube, preventing oil leaks and contaminants from entering the engine. This cap is integral to the following components and systems:

- Arrangement and Integration: The filler cap is part of the overall arrangement of the engine’s lubrication system. It ensures that the oil fill tube is securely sealed, allowing for easy and clean oil addition during maintenance.

- Crankcase Breather System: In conjunction with the crankcase breather, the filler cap helps maintain proper pressure within the crankcase. This is vital for the efficient operation of the breather system, which expels gases from the crankcase to prevent buildup and ensure optimal engine performance.

- Breather and Valve Cover: The filler cap works in tandem with the breather and valve cover to regulate the flow of air and gases. This coordination is essential for maintaining a balanced environment within the engine, enhancing its longevity and efficiency.

- Dipstick and Oil Fill: The filler cap is directly connected to the dipstick and oil fill mechanism. It allows for accurate oil level checks and ensures that the oil fill process is contaminant-free, protecting the engine’s internal components.

- Engine Barring and Lubrication: During engine barring procedures, the filler cap ensures that the lubrication system remains intact. This is important for preventing oil loss and maintaining consistent lubrication during engine startups and shutdowns.

- Full Flow Oil Filter System: The cap interacts with the full flow oil filter system by ensuring that the oil being added is clean and free from debris. This contributes to the filter’s efficiency in capturing contaminants, thereby prolonging the engine’s service life.

- Oil Gauge and Oil Gauge Tube: The filler cap is also part of the oil gauge system. It ensures that the oil gauge tube remains sealed, providing accurate oil level readings and aiding in the monitoring of the engine’s lubrication status.

- Rocker Lever and Valve Covers: The filler cap complements the rocker lever and valve covers by maintaining a sealed environment. This is important for the proper functioning of these covers, which are critical for the engine’s valve train operation.

Conclusion

In summary, the part 101322 Filler Cap plays a significant role in various engine systems by ensuring seals are maintained, contaminants are kept out, and the lubrication system operates efficiently. Its integration with other components underscores its importance in the overall functionality and maintenance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.