This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3803575 Oil Seal Kit is a specialized component designed for use in heavy-duty truck engines. Its primary role is to prevent oil leaks and maintain the integrity of rotating components within the engine. This kit is significant in the maintenance and operation of heavy-duty trucks, contributing to the engine’s efficiency and longevity 1.

Purpose and Function

This Cummins part plays a role in preventing oil leaks by creating a barrier between the rotating components and the stationary parts of the engine. This barrier ensures that oil remains within the lubrication system, where it is needed to reduce friction and wear on moving parts. By maintaining the proper oil levels and preventing leaks, the kit contributes to the overall efficiency and durability of the engine 2.

Key Features

The Cummins 3803575 is constructed using high-quality materials that are resistant to wear and capable of withstanding the high temperatures and pressures found within heavy-duty truck engines. The design specifications of the kit include precision-engineered seals that fit snugly around rotating shafts, ensuring a tight seal. Additionally, the kit may include features such as reinforced backing rings to enhance durability and performance under demanding conditions 3.

Benefits

Using the Cummins 3803575 offers several benefits. It helps improve engine performance by ensuring that oil remains where it is needed, reducing friction and wear on engine components. This can lead to reduced maintenance costs over time, as the need for repairs due to oil leaks is minimized. Furthermore, the kit enhances the reliability of the engine, contributing to its longevity and overall efficiency.

Installation Process

Proper installation of this part is crucial for ensuring optimal performance. The process involves several steps, including preparing the engine by cleaning the area around the seal location, removing the old seals, and installing the new seals according to the manufacturer’s instructions. Tools such as seal installation tools may be required to ensure the seals are properly seated. Following best practices during installation, such as lubricating the seals before installation, can help ensure they function correctly.

Maintenance and Troubleshooting

To maintain the longevity and performance of the Cummins 3803575, regular inspections are recommended. This includes checking for signs of wear or damage and ensuring that the seals are properly seated. Common issues that may arise include oil leaks, which can often be traced back to improper installation or wear on the seals. Troubleshooting steps may involve re-examining the installation process, replacing worn seals, or addressing any underlying issues that may be contributing to seal failure.

Manufacturer - Cummins

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to quality and innovation in manufacturing automotive components. With a history of producing reliable and high-performance engine parts, Cummins has built a reputation for excellence. The company’s dedication to research and development ensures that its products, including the Cummins 3803575, meet the demanding requirements of heavy-duty truck engines.

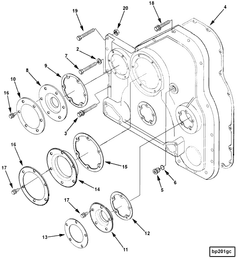

Components of Cummins Oil Seal Kit 3803575

The Cummins Oil Seal Kit 3803575 is a comprehensive assembly designed to facilitate the replacement and maintenance of oil seals in various engine applications. This kit includes several critical components, each playing a distinct role in ensuring the effective sealing of oil within the engine. Below is a detailed description of each component included in the kit:

Carrier Gasket (3600470)

The Carrier Gasket is a fundamental component within the Oil Seal Kit. Its primary function is to provide a secure and stable platform for the oil seal to be mounted upon. This gasket ensures that the oil seal is correctly positioned and aligned within the engine housing, which is crucial for the seal’s effectiveness. The gasket also helps in distributing the clamping force evenly across the seal, preventing any potential damage or misalignment that could lead to oil leaks.

Oil Seal (3895064)

The Oil Seal is the core component of the kit, responsible for preventing oil leakage from the engine. This seal is designed to fit snugly within the engine housing, creating a barrier that keeps oil contained within the system. The oil seal must be in perfect condition to ensure that it can withstand the pressures and temperatures within the engine environment. The inclusion of a new oil seal in the kit ensures that any existing seal that may be worn or damaged is replaced, maintaining the integrity of the engine’s oil system.

Clamping Ring (3895068)

The Clamping Ring plays a role in securing the oil seal in place. This ring applies the necessary pressure to the oil seal, ensuring it remains firmly in position against the rotating shaft or component it is designed to seal. The clamping ring must be correctly installed to avoid any movement of the oil seal, which could lead to ineffective sealing and potential oil leaks. The ring is typically made from a durable material that can withstand the mechanical stresses and high temperatures encountered in engine operations.

Each of these components is meticulously designed to work in harmony within the Oil Seal Kit 3803575, ensuring that the oil seal replacement process is efficient, effective, and results in a secure, leak-free seal within the engine. The careful selection and inclusion of these components demonstrate Cummins’ commitment to providing high-quality, reliable solutions for engine maintenance and repair.

Conclusion

The Cummins 3803575 Oil Seal Kit is an essential component for maintaining the efficiency and longevity of heavy-duty truck engines. By preventing oil leaks and ensuring the proper functioning of rotating components, this kit plays a crucial role in engine maintenance. Its high-quality construction, ease of installation, and the comprehensive nature of its components make it a reliable choice for engine repair and maintenance professionals.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.