This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

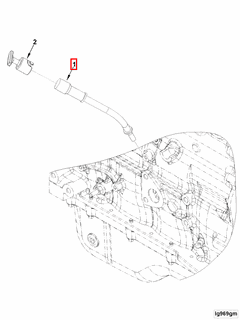

Introduction to Oil Gauge Tubes

Oil gauge tubes are essential components in the lubrication system of commercial trucks. They provide critical information about the oil level within the engine, ensuring smooth and efficient operation. For engineers, mechanics, truck drivers, and fleet operators, understanding the function and importance of an oil gauge tube is crucial.

How an Oil Gauge Tube Works

An oil gauge tube, such as the Cummins part #4932520, is designed to measure the oil level in the engine’s oil pan. This component consists of a tube that runs from the oil pan to the oil pressure gauge on the dashboard. Connected to a float mechanism, the tube’s operation is straightforward yet critical: as the oil level changes, the float moves accordingly. When the oil level is low, the float descends, and the gauge indicates a lower oil level. Conversely, when the oil level is sufficient, the float ascends, and the gauge shows a higher oil level 1.

Purpose of the Cummins Oil Gauge Tube Part #4932520

The Cummins oil gauge tube part #4932520 is instrumental in preserving engine health. By delivering real-time information about the oil level, it helps prevent engine damage caused by inadequate lubrication. This is especially crucial in commercial trucks, where engines are perpetually under stress and demand reliable lubrication to sustain performance and longevity 2.

Role in the Operation of a Truck

For truck drivers and fleet operators, the oil gauge tube is a pivotal component that ensures the engine operates within safe parameters. Consistent monitoring of the oil level helps prevent unexpected breakdowns and expensive repairs. Mechanics and engineers depend on the oil gauge tube to diagnose and address potential issues before they escalate into significant problems 3.

Troubleshooting and Maintenance

Regular maintenance of the oil gauge tube is vital to ensure accurate readings and reliable performance. Here are some troubleshooting and maintenance tips:

-

Check for Leaks: Inspect the oil gauge tube for any signs of leaks or damage. A leaking tube can result in inaccurate oil level readings and potential engine damage.

-

Clean the Tube: Over time, the oil gauge tube may become obstructed with debris. Regularly cleaning the tube ensures that the float mechanism functions smoothly and provides precise readings.

-

Replace Worn Components: If the float mechanism or other components of the oil gauge tube are worn or damaged, they should be replaced promptly. Using genuine Cummins parts ensures compatibility and reliability.

-

Monitor Oil Levels: Regularly check the oil level and compare it with the gauge reading. Any discrepancies may indicate a problem with the oil gauge tube or other components of the lubrication system.

Cummins Oil Gauge Tube (Part 4932520) Compatibility

The Cummins Oil Gauge Tube, part number 4932520, is designed to fit a variety of Cummins engines, ensuring accurate oil level monitoring across different engine models. Here’s a detailed look at the compatibility of this part with various Cummins engines:

B4.5 Series

- B4.5 RGT: This engine model is compatible with the Oil Gauge Tube 4932520, ensuring that operators can monitor oil levels effectively.

ISB/ISD4.5 Series

- ISB/ISD4.5 CM2150 B119: The Oil Gauge Tube 4932520 is suitable for this engine, providing reliable oil level readings.

- ISBE CM800: This engine model also fits the Oil Gauge Tube 4932520, ensuring proper oil level monitoring.

ISBE Series

- ISBE4 CM850: The Oil Gauge Tube 4932520 is compatible with this engine, ensuring accurate oil level readings.

QSB4.5 Series

- QSB4.5 CM2250 EC: This engine model is compatible with the Oil Gauge Tube 4932520, ensuring accurate oil level monitoring.

- QSB4.5 CM850 (CM2850): The Oil Gauge Tube 4932520 fits this engine, providing reliable oil level readings.

QSB6.7 Series

- QSB6.7 CM2250: The Oil Gauge Tube 4932520 is suitable for this engine model, ensuring accurate oil level monitoring.

- QSB6.7 CM2350 B105: This engine model is compatible with the Oil Gauge Tube 4932520, ensuring proper oil level readings.

- QSB6.7 CM850 (CM2850): The Oil Gauge Tube 4932520 fits this engine, providing reliable oil level readings.

QSB7 Series

- QSB7 CM2880 B117: The Oil Gauge Tube 4932520 is compatible with this engine model, ensuring accurate oil level monitoring.

This comprehensive compatibility ensures that the Oil Gauge Tube 4932520 can be used across a wide range of Cummins engines, providing a reliable solution for oil level monitoring.

Role of Part 4932520 Oil Gauge Tube in Engine Systems

The 4932520 Oil Gauge Tube is an integral component in the accurate measurement and monitoring of oil levels within an engine system. This tube facilitates the connection between the dipstick and the oil level gauge, ensuring a seamless flow of information regarding the oil status.

When the dipstick is inserted into the Oil Gauge Tube, it provides a direct measurement of the oil level within the engine. The dipstick, upon removal, offers a visual and tactile indication of the oil quantity, which is then translated into a readable format by the oil level gauge. This gauge, often located on the instrument panel, displays the oil level to the operator, allowing for timely maintenance and ensuring the engine operates within optimal conditions.

The Oil Gauge Tube also plays a role in maintaining the integrity of the oil level measurement system. By providing a sealed pathway for the dipstick, it prevents oil leakage and contamination, which could otherwise lead to inaccurate readings and potential engine damage.

Conclusion

In summary, the 4932520 Oil Gauge Tube is a key element in the engine’s oil level monitoring system, working in conjunction with the dipstick and oil level gauge to provide accurate and reliable oil level readings. This ensures the engine’s lubrication system functions correctly, contributing to the overall performance and longevity of the engine.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.