This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

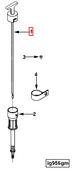

Introduction to Oil Gauge Tubes

Oil gauge tubes are critical components in the engine systems of commercial trucks. They provide essential information about the oil level and pressure, ensuring the engine operates smoothly and efficiently. This article delves into the specifics of the Cummins Oil Gauge Tube, part number 3939143, its functionality, and its importance in maintaining engine health.

Basic Concepts Related to Oil Gauge Tubes

An oil gauge tube is a component that measures the oil level and pressure within the engine. It typically consists of a tube that extends from the oil pan to the oil pressure sensor or gauge. The tube allows oil to flow through it, which is then measured by the sensor. This measurement is crucial for ensuring that the engine has adequate lubrication, preventing wear and tear on critical components 1.

Purpose of the Cummins Oil Gauge Tube (Part #3939143)

The Cummins Oil Gauge Tube, part number 3939143, plays a pivotal role in the operation of commercial trucks. Its primary function is to monitor the oil level and pressure within the engine. By providing real-time data to the driver and mechanics, it helps in maintaining optimal engine performance and preventing potential breakdowns 2.

How the Cummins Oil Gauge Tube Works

The Cummins Oil Gauge Tube works by connecting the oil pan to the oil pressure sensor. As oil flows through the tube, it creates a pressure differential that is measured by the sensor. This pressure is then translated into a reading on the oil gauge, allowing the driver or mechanic to monitor the oil level and pressure. If the oil level drops below a certain threshold, the gauge will alert the driver, prompting immediate action to prevent engine damage 3.

Importance in Truck Operations

In the context of commercial trucks, the oil gauge tube is indispensable. It ensures that the engine remains adequately lubricated, which is critical for the longevity and efficiency of the vehicle. Regular monitoring of the oil level and pressure can prevent catastrophic engine failure, reducing downtime and maintenance costs.

Troubleshooting and Maintenance

Proper maintenance of the Cummins Oil Gauge Tube is essential for its longevity and accuracy. Here are some troubleshooting and maintenance tips:

-

Regular Inspections: Periodically inspect the oil gauge tube for any signs of wear, leaks, or blockages. Any damage can lead to inaccurate readings and potential engine issues.

-

Cleaning: Ensure that the oil gauge tube is free from contaminants. Any debris or sludge can obstruct the flow of oil and affect the accuracy of the readings.

-

Replacement: If the oil gauge tube is damaged or shows signs of wear, it should be replaced promptly. Using genuine Cummins parts ensures compatibility and reliability.

-

Calibration: Ensure that the oil pressure sensor is properly calibrated. An inaccurate sensor can lead to incorrect readings, potentially causing engine damage.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of engines and related components for commercial trucks. Known for its durability and reliability, Cummins products are trusted by fleet operators worldwide. The company’s commitment to innovation and quality ensures that its parts, including the Oil Gauge Tube part number 3939143, meet the highest standards.

Compatibility of Cummins Oil Gauge Tube 3939143

The Cummins Oil Gauge Tube part number 3939143 is designed to fit several engine models. This part is integral for monitoring oil levels and ensuring the engine’s proper functioning. Here is a detailed look at the compatibility of this part with various Cummins engines:

- 6B5.9: The 6B5.9 engine benefits from the 3939143 Oil Gauge Tube, ensuring accurate oil level readings and maintaining engine health.

- ISC CM2150 and ISL CM2150: Both the ISC CM2150 and ISL CM2150 engines are compatible with the 3939143 Oil Gauge Tube. This part is crucial for these engines to monitor oil levels effectively.

- ISL9 CM2150 SN and ISL9 CM2250: The 3939143 Oil Gauge Tube is also suitable for the ISL9 CM2150 SN and ISL9 CM2250 engines. It provides essential oil level monitoring for these models.

- QSB5.9 30 CM550: Lastly, the QSB5.9 30 CM550 engine is another model that can utilize the 3939143 Oil Gauge Tube. This part ensures that the engine’s oil levels are accurately monitored, contributing to its overall performance and longevity.

Role of Part 3939143 Oil Gauge Tube in Engine Systems

The part 3939143 Oil Gauge Tube is an integral component in the accurate measurement and monitoring of oil levels within an engine system. This tube facilitates the connection between the dipstick and the oil level gauge, ensuring a seamless flow of information regarding the engine’s oil status.

When the dipstick is inserted into the Oil Gauge Tube, it measures the oil level directly. The tube then transmits this measurement to the gauge, which displays the oil level to the user. This process is essential for maintaining proper lubrication of engine components, preventing wear and ensuring optimal performance.

The Oil Gauge Tube also plays a role in the overall integrity of the oil measurement system. By providing a direct and unobstructed path for the dipstick, it ensures that the oil level readings are accurate and reliable. This accuracy is vital for timely oil changes and maintenance, contributing to the longevity and efficiency of the engine.

Conclusion

The Cummins Oil Gauge Tube, part number 3939143, is a vital component in the engine systems of commercial trucks. Understanding its function, importance, and maintenance can significantly contribute to the longevity and efficiency of the vehicle. By adhering to proper maintenance practices and using genuine Cummins parts, fleet operators can ensure that their trucks remain in optimal condition.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.