This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

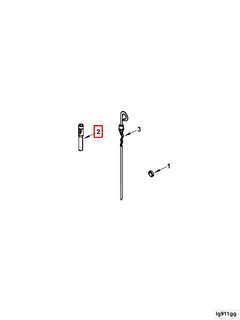

The Oil Gauge Tube 3935617, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This part plays a role in the engine’s lubrication system by providing accurate oil level readings, which is important for maintaining engine health and performance 2.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is a component within the engine lubrication system that facilitates the measurement of oil levels. It operates by allowing oil to flow into a gauge or sensor, which then provides a reading of the oil level within the engine. Accurate oil level readings are important for ensuring that the engine receives adequate lubrication, which helps in reducing wear and maintaining optimal performance 3.

Purpose of the 3935617 Oil Gauge Tube

This Cummins part is designed to integrate into the lubrication system of a truck, providing precise oil level readings. Its function is to allow oil to flow into the gauge, where the level can be monitored. This component plays a role in maintaining engine health by ensuring that oil levels are within the required range, thus supporting efficient lubrication and reducing the risk of engine damage due to insufficient oil 1.

Key Features

The 3935617 is constructed from high-quality materials, ensuring durability and reliability. Its design includes features that enhance performance, such as a robust connection to the oil system and a precise measurement mechanism. These attributes contribute to the tube’s ability to provide accurate and consistent oil level readings over time 4.

Benefits

Using the 3935617 offers several benefits. It contributes to improved engine performance by ensuring that oil levels are maintained within the optimal range. The durable construction of the tube enhances its longevity, reducing the need for frequent replacements. Additionally, reliable oil level monitoring helps in preventing engine issues related to lubrication, thus supporting overall engine health 2.

Installation Process

Installing the 3935617 involves several steps to ensure proper fitting and function. Preparatory steps include ensuring the engine is cool and the oil system is depressurized. Tools required may include wrenches and possibly a torque wrench. The installation process involves connecting the tube to the oil system and securing it in place. Following manufacturer guidelines ensures correct installation and function 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 3935617, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage at regular intervals. Cleaning the tube and its connections can help prevent issues related to contamination. If any signs of damage or malfunction are observed, considering replacement is advisable to maintain accurate oil level readings 1.

Troubleshooting Common Issues

Common problems associated with oil gauge tubes may include inaccurate readings or leaks. Troubleshooting these issues involves checking the connections for leaks and ensuring that the tube is securely fitted. If inaccurate readings are observed, inspecting the gauge or sensor for malfunctions may be necessary. Addressing these issues promptly helps in maintaining the integrity of the lubrication system 4.

Cummins Overview

Cummins Inc. is a leader in the commercial truck industry, known for its extensive product range and commitment to quality. With a history of innovation and excellence, Cummins has established a reputation for producing reliable and high-performance components. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a trusted provider in the industry 2.

Cummins Oil Gauge Tube 3935617 Compatibility

The Cummins Oil Gauge Tube part number 3935617 is designed to integrate seamlessly with a variety of engine models, ensuring accurate oil pressure readings and maintaining engine health. This part is meticulously engineered to fit specific engine configurations, providing reliable performance across different applications 3.

Engine Compatibility

-

6B5.9 Series

- The 3935617 is engineered to fit within the 6B5.9 engine series. This compatibility ensures that the gauge tube can effectively monitor oil pressure, a critical parameter for engine operation. The precise fitment guarantees that the tube can be securely installed without compromising the engine’s integrity.

-

Other Cummins Engines

- While the primary focus is on the 6B5.9 series, the 3935617 is also compatible with other Cummins engines that share similar design specifications. This broad compatibility allows for versatile use across multiple engine models, making it a valuable component for maintenance and repair 1.

Installation and Functionality

The installation of the 3935617 is straightforward, designed to fit into the designated oil pressure port on the engine block. This ensures that the tube can accurately measure oil pressure and relay this information to the gauge on the dashboard. The design of the tube is such that it can withstand the high temperatures and pressures typical of engine environments, ensuring durability and long-term reliability 4.

Importance of Proper Fitment

Proper fitment of the Oil Gauge Tube is crucial for maintaining engine performance and safety. An ill-fitting tube can lead to inaccurate readings, potentially resulting in engine damage due to incorrect operational decisions based on faulty data. The 3935617 part number is specifically engineered to meet the stringent requirements of Cummins engines, ensuring that users can trust the accuracy and reliability of the oil pressure readings 2.

Maintenance and Replacement

Regular maintenance of the Oil Gauge Tube is essential to ensure continued accuracy and reliability. Periodic checks should be performed to ensure that the tube is securely fitted and free from damage or wear. Replacement should be carried out using genuine Cummins parts to maintain the integrity of the engine’s oil pressure monitoring system 3.

Role of Part 3935617 Oil Gauge Tube in Engine Systems

The 3935617 is an integral component in the accurate measurement and monitoring of oil levels within an engine system. This tube facilitates the connection between the oil reservoir and the oil gauge, ensuring that the gauge receives a consistent and reliable oil sample.

In the context of an engine, the oil gauge tube works in conjunction with the oil level sensor to provide real-time data on the oil level. This data is essential for maintaining optimal engine performance and preventing potential damage due to low oil levels.

The tube is designed to withstand the pressures and temperatures within the engine compartment, ensuring durability and consistent performance. It plays a significant role in the overall lubrication system, which includes the oil pump, oil filter, and various engine bearings.

By providing a clear and unobstructed path for oil to travel from the reservoir to the gauge, the 3935617 helps in maintaining the integrity of the oil level readings. This, in turn, allows for timely maintenance and ensures that the engine operates within safe parameters.

Conclusion

In summary, the 3935617 is a key component in the engine’s lubrication system, contributing to the accurate monitoring of oil levels and the overall health of the engine. Its design, compatibility, and role in the engine system make it a critical part for maintaining engine performance and longevity 4.

-

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012

↩ ↩ ↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ ↩ ↩ ↩ -

An Introduction to Engine Testing and Development, Richard D. Atkins, SAE International, 2009

↩ ↩ ↩ ↩ -

Tyre and Vehicle Dynamics, Hans B. Pacejka, Butterworth-Heinemann, 2006

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.