This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

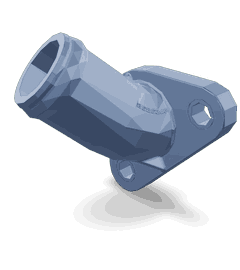

The Cummins 3686343 Oil Filler Tube is a component designed for use in heavy-duty truck engines. Its primary role is to facilitate the addition of oil to the engine, ensuring that the lubrication system operates effectively. Proper maintenance of this part is significant for the overall performance and longevity of the engine 1.

Function and Operation

The Oil Filler Tube operates as a conduit for oil addition within the engine system. It is positioned to allow for easy access during oil changes, ensuring that the engine receives the necessary lubrication to function smoothly. The tube is designed to integrate seamlessly with the engine’s oil cap, providing a secure pathway for oil to reach the crankcase. This ensures that the engine components remain well-lubricated, reducing friction and wear 2.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and resistance to the harsh conditions within an engine environment. Its design includes a robust build that can withstand high pressures and temperatures. The tube is engineered to fit precisely within the engine’s oil cap, minimizing the risk of leaks and ensuring a tight seal. Additionally, the tube’s smooth interior surface facilitates the easy flow of oil, enhancing the efficiency of the lubrication process 3.

Benefits

Utilizing the 3686343 offers several advantages. It contributes to improved engine performance by ensuring consistent and adequate lubrication. The tube’s durable construction enhances the engine’s longevity, reducing the frequency of replacements. Furthermore, its design simplifies the oil change process, making maintenance more straightforward and efficient for users.

Installation Process

Installing the Oil Filler Tube requires careful attention to detail to ensure proper fitting and functionality. Begin by ensuring the engine is cool and the oil has been drained. Remove the old tube from the oil cap, taking care not to damage surrounding components. Insert the new tube into the oil cap, ensuring it is seated correctly. Verify that the tube is secure and there are no gaps that could lead to leaks. Finally, perform a visual inspection to confirm the installation is correct before restarting the engine.

Maintenance Tips

To prolong the lifespan of the 3686343, regular maintenance is recommended. Inspect the tube during routine oil changes for signs of wear, damage, or leaks. Clean the tube and surrounding areas to remove any debris or contaminants that could affect its performance. Address any issues promptly to prevent further damage to the engine. Following these practices will help maintain the tube’s integrity and ensure the engine operates efficiently.

Troubleshooting Common Issues

Users may encounter several issues with the Oil Filler Tube, including leaks, blockages, and fitting complications. Leaks can often be resolved by ensuring the tube is properly seated in the oil cap and that there are no cracks or damage to the tube itself. Blockages may require cleaning or, in some cases, replacement of the tube. Fitting complications can usually be addressed by verifying the tube’s compatibility with the engine model and ensuring correct installation procedures are followed.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its high-quality engines and components. With a rich history of innovation and excellence, Cummins offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s commitment to quality and reliability is evident in its components, including the 3686343.

Compatibility

The Oil Filler Tube part number 3686343 is designed to fit a range of Cummins engines, ensuring proper oil level monitoring and maintenance. This part is integral for maintaining the integrity of the engine’s lubrication system. Below is a detailed overview of the compatibility of this oil filler tube with various Cummins engines:

ISX15 Series

- ISX15 CM2250

- ISX15 CM2250 SN

ISX15 CM2350 Series

- ISX15 CM2350 X101

QSX15 Series

- QSX15 CM2350 X105

X15 Series

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

This compatibility ensures that the oil filler tube 3686343 can be used across a broad range of Cummins engines, facilitating ease of maintenance and ensuring the longevity of the engine’s lubrication system.

Understanding the Integration of Part 3686343 in Engine Systems

The part 3686343 is an essential component in the arrangement of various engine systems, facilitating the smooth operation and maintenance of the engine. This component is specifically designed to interface with the oil fill system, ensuring that the engine receives the necessary lubrication for optimal performance.

Role in the Oil Fill System

The Oil Filler Tube serves as a conduit for adding oil to the engine. It is strategically positioned to allow for easy access during maintenance routines. The tube is connected to the oil fill cap, which is typically located on the valve cover of the engine. This setup ensures that oil can be efficiently poured into the engine without spillage, maintaining a clean and safe working environment.

Interaction with Engine Components

- Valve Cover: The Oil Filler Tube is directly attached to the valve cover, which houses the valve train components. This connection point is vital for ensuring that oil reaches the valve train, lubricating the camshaft, lifters, and other moving parts within the cover.

- PCV System: The Positive Crankcase Ventilation (PCV) system works in conjunction with the Oil Filler Tube. The PCV valve, often mounted near the Oil Filler Tube, helps manage crankcase pressure by allowing fresh air to enter the crankcase and venting harmful gases to the intake manifold. This interaction ensures that the engine operates efficiently and reduces emissions.

- Oil Level Sensor: In many modern engines, the Oil Filler Tube is equipped with an oil level sensor. This sensor monitors the oil level within the engine and sends data to the engine control unit (ECU). The ECU uses this information to alert the driver if the oil level is low, ensuring that the engine is always adequately lubricated.

- Breather System: The Oil Filler Tube also plays a role in the breather system of the engine. It allows for the release of pressure build-up within the crankcase, preventing oil leaks and maintaining engine integrity. This is particularly important during high-performance driving conditions where pressure fluctuations are more pronounced.

Maintenance and Operational Benefits

Incorporating the Oil Filler Tube into the engine system offers several maintenance and operational benefits. It simplifies the oil change process by providing a clear and accessible point for oil addition. Additionally, the design of the tube often includes features such as splash guards or funnels to minimize mess and improve safety during oil changes.

Conclusion

Overall, the integration of the Oil Filler Tube within the engine system enhances the efficiency and reliability of the lubrication process, contributing to the longevity and performance of the engine. Proper maintenance and understanding of this part’s role in the engine system are crucial for ensuring optimal engine operation.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

Michael Hilgers, Alternative Powertrains and Extensions to the Conventional Powertrain, Springer Nature, 2023.

↩ -

Kazimierz Lejda and Pawel Wos, Internal Combustion Engines, InTech, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.