5271009

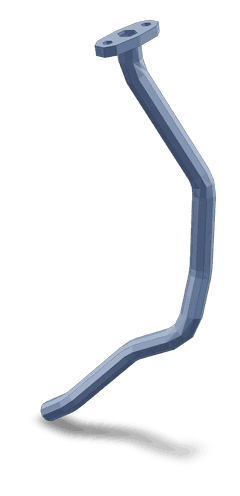

Tur Oil Drain Tube

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tur Oil Drain Tube (5271009), manufactured by Cummins, is a critical component for commercial trucks. Cummins, a leader in diesel engines and related technologies, designs this part to improve the efficiency and reliability of oil drainage systems in heavy-duty applications. Effective oil drainage is essential for maintaining engine health and performance, ensuring that used oil is efficiently removed from the engine to reduce contamination and wear risks 1.

Function and Operation

The Tur Oil Drain Tube operates within the engine’s oil system to facilitate the removal of used oil. When the engine oil reaches the end of its service life, the drain tube provides a pathway for the oil to exit the engine and be collected for disposal or recycling. This process is vital for maintaining the cleanliness and efficiency of the engine’s lubrication system. The tube is designed to handle oil flow without leakage, ensuring a safe and effective drainage process 2.

Purpose of the Tur Oil Drain Tube

In the operation and maintenance of a truck’s engine, the Tur Oil Drain Tube plays a significant role. By enabling efficient oil drainage, it helps ensure that the engine remains free from contaminants that can accumulate in used oil. This contributes to the longevity and performance of the engine, as clean oil is crucial for reducing friction and wear on engine components 3.

Key Features

The Tur Oil Drain Tube (5271009) is characterized by its robust design and construction. It is made from high-quality materials resistant to the high temperatures and pressures found within an engine environment. The tube may incorporate patented technologies that enhance its functionality, such as improved sealing mechanisms to prevent leaks. Its design is tailored to fit seamlessly within the engine’s oil system, ensuring compatibility and ease of installation 4.

Benefits of Using the Tur Oil Drain Tube

Utilizing the Tur Oil Drain Tube offers several advantages. It provides improved oil drainage efficiency, which is beneficial for maintaining engine cleanliness and performance. The design of the tube also contributes to ease of maintenance, as it is engineered to be durable and long-lasting. Furthermore, by ensuring efficient oil drainage, the tube helps protect the engine from the detrimental effects of contaminated oil, thereby supporting overall engine health 1.

Installation and Compatibility

For the proper installation of the Tur Oil Drain Tube (5271009), it is important to follow manufacturer guidelines to ensure compatibility with the specific Cummins engine model in use. Installation should be carried out by qualified personnel to maintain the integrity of the engine’s oil system. Specific requirements for installation may include ensuring the correct orientation of the tube and verifying that all connections are secure to prevent leaks 2.

Maintenance and Troubleshooting

Regular maintenance of the Tur Oil Drain Tube is recommended to ensure its optimal performance. This may include periodic inspections for signs of wear or damage and ensuring that all connections remain tight. Common issues that may arise include leaks or blockages, which can often be addressed by re-securing connections or cleaning the tube as necessary 3.

Safety Considerations

When working with the Tur Oil Drain Tube, it is important to observe safety practices to protect against the hazards associated with hot oil and potential leaks. This includes allowing the engine to cool before attempting any maintenance or drainage procedures and ensuring that the tube is properly sealed to prevent oil from escaping during operation 4.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and transportation markets worldwide. The company’s product range includes engines, filtration, emissions solutions, and power generation products, all designed to meet the demanding requirements of their applications.

Cummins Tur Oil Drain Tube 5271009 Compatibility

The Tur Oil Drain Tube, part number 5271009, manufactured by Cummins, is designed to fit seamlessly within a variety of engine models. This component is integral to the engine’s oil management system, ensuring efficient oil drainage and preventing oil accumulation that could lead to engine damage.

Engine Compatibility

- QSB3.3 CM2250 EC

- QSB6.7 CM2300 EC

- QSB6.7 CM2350 EC

These engines, part of the Cummins QSB series, are known for their robust performance and reliability in various applications, including industrial, marine, and agricultural sectors. The Tur Oil Drain Tube 5271009 is specifically engineered to fit these models, ensuring optimal performance and longevity of the engine.

Installation and Functionality

The Tur Oil Drain Tube 5271009 is designed to be a straightforward addition to the engine’s oil system. It is typically installed during the engine assembly process or as part of routine maintenance. The tube’s design allows for efficient oil drainage, reducing the risk of oil leaks and ensuring that the engine operates smoothly.

Importance of Proper Installation

Proper installation of the Tur Oil Drain Tube is crucial for maintaining engine health. Incorrect installation can lead to oil leaks, reduced engine efficiency, and potential engine damage. Technicians should follow the manufacturer’s guidelines when installing this component to ensure it functions as intended.

Maintenance Considerations

Regular maintenance of the Tur Oil Drain Tube is essential to ensure it remains in good condition. This includes checking for any signs of wear or damage during routine engine inspections. If any issues are detected, the tube should be replaced promptly to prevent potential engine problems.

Role of Part 5271009 Tur Oil Drain Tube in Engine Systems

The 5271009 Tur Oil Drain Tube is a vital component in the efficient operation of turbocharger systems within various engine setups. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that oil does not accumulate to problematic levels.

In the context of turbocharger plumbing, the Tur Oil Drain Tube is integrated into the oil return lines. It allows excess oil, which has been used to lubricate the turbocharger bearings and other moving parts, to be returned to the engine’s oil sump. This process is vital for maintaining the correct oil levels and pressure within the turbocharger, thereby enhancing its performance and longevity.

When considering the plumbing aspect, the Tur Oil Drain Tube connects to the turbocharger’s oil drain port. From there, it routes the used oil back into the engine’s lubrication system. This connection is typically made using high-quality hoses and fittings designed to withstand the pressures and temperatures associated with turbocharger operation.

In a turbocharger system, the efficient drainage of oil is paramount. The turbocharger relies on a steady supply of oil for lubrication, cooling, and sealing. The Tur Oil Drain Tube ensures that any surplus oil is promptly removed, preventing oil starvation and maintaining optimal turbocharger function.

Overall, the 5271009 Tur Oil Drain Tube plays a significant role in the turbocharger’s lubrication circuit, contributing to the reliable and efficient operation of the entire engine system.

Conclusion

The Tur Oil Drain Tube (5271009) by Cummins is a crucial component for maintaining the efficiency and reliability of oil drainage systems in commercial trucks. Its robust design, ease of installation, and maintenance benefits contribute to the longevity and performance of the engine. Proper installation and regular maintenance are essential to ensure the optimal functioning of this part, thereby supporting the overall health and efficiency of the engine system.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ ↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ ↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ ↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.