This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

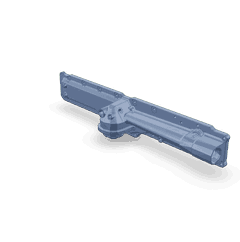

The Oil Filter Cooler Head, identified by Part #4952497, is a component manufactured by Cummins, a renowned leader in the production of diesel engines and related technologies. This part is integral to the lubrication systems of heavy-duty trucks, ensuring that the engine oil remains at an optimal temperature and cleanliness. Cummins’ reputation for quality and reliability underscores the significance of this component in maintaining the performance and longevity of heavy-duty truck engines .

Basic Concepts

Oil filtration and cooling are fundamental processes in the maintenance of heavy-duty truck engines. The oil filter plays a role in removing contaminants from the oil, while the cooler helps in dissipating excess heat. The Oil Filter Cooler Head is a component that facilitates these processes by integrating the filtration and cooling functions into a single unit. This integration ensures that the oil circulating through the engine is both clean and at the correct temperature, which is vital for the engine’s efficient operation .

Function and Operation

The Oil Filter Cooler Head operates within the truck’s lubrication system by channeling engine oil through a filtration medium that captures impurities. Simultaneously, the oil passes through a cooling section where it exchanges heat with the surrounding environment or a coolant fluid. This dual-function design allows the Oil Filter Cooler Head to maintain the oil at an optimal temperature while ensuring it remains free from contaminants. Its operation is seamless with the engine’s lubrication circuit, interacting with the oil pump, engine bearings, and other lubrication points to provide consistent oil quality throughout the system .

Purpose and Role

The specific purpose of the Oil Filter Cooler Head is to maintain the optimal temperature and cleanliness of the engine oil. By doing so, it contributes to the engine’s performance and longevity. Clean oil reduces friction between moving parts, which in turn minimizes wear and tear. Maintaining the oil at the correct temperature ensures that it retains its viscosity, which is crucial for effective lubrication. Together, these factors help in preserving the engine’s efficiency and extending its operational life.

Key Features

The Oil Filter Cooler Head is designed with several features that enhance its functionality. It is constructed from durable materials that can withstand the high pressures and temperatures of the engine lubrication system. The design incorporates efficient filtration media and a cooling mechanism that works in concert to provide superior oil quality. Additionally, the part may include unique attributes such as anti-drainback valves to prevent oil loss when the engine is not in operation, or gaskets and seals that ensure a secure fit and prevent leaks.

Benefits

The advantages provided by the Oil Filter Cooler Head include improved engine efficiency due to better lubrication, reduced wear on engine components as a result of clean oil, and enhanced reliability of the lubrication system. These benefits contribute to the overall performance of the heavy-duty truck, ensuring that it operates smoothly and efficiently under a variety of conditions.

Installation and Compatibility

Proper installation of the Oil Filter Cooler Head is important to ensure its effective operation within the truck’s lubrication system. Installation guidelines typically include checking for compatibility with the specific truck model, ensuring that all connections are secure, and verifying that the part is correctly aligned with the oil flow direction. It is also important to follow any manufacturer-specific instructions to ensure that the part functions as intended.

Maintenance and Troubleshooting

Routine maintenance practices for the Oil Filter Cooler Head include regular inspection for signs of wear or damage, ensuring that all connections remain tight, and monitoring the oil quality to ensure that the filtration and cooling functions are performing effectively. Troubleshooting common issues may involve checking for leaks, verifying the integrity of the filtration media, and ensuring that the cooling mechanism is operating correctly. Addressing these issues promptly can help in maintaining the optimal performance of the Oil Filter Cooler Head.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power generation and propulsion systems. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to manufacturing high-quality components is evident in its extensive product line, which includes engines, filtration systems, and aftermarket parts designed to meet the demanding requirements of heavy-duty applications.

Understanding the Role of Part 4952497 in Engine Systems

Part 4952497, the Oil Filter Cooler Head, is an essential component in the efficient operation of engine systems, particularly when integrated with an engine oil cooler and an oil filter. This component facilitates the cooling process of the engine oil, ensuring optimal engine performance and longevity.

Integration with Engine Oil Cooler

The Oil Filter Cooler Head (part 4952497) is designed to work in conjunction with the engine oil cooler. The oil cooler is responsible for reducing the temperature of the engine oil, which, if left unchecked, can reach levels that may cause damage to engine components. The cooler head plays a significant role in this process by directing the flow of oil into the cooler, allowing for efficient heat exchange. As the oil passes through the cooler, it is exposed to ambient air or a coolant, which absorbs the heat, resulting in a reduction of oil temperature. This cooled oil then returns to the engine, providing lubrication with reduced thermal stress on engine parts.

Function within the Oil Filtration System

In addition to its role in the cooling process, the Oil Filter Cooler Head is integral to the oil filtration system. It ensures that the oil, after being cooled, flows into the oil filter. The filter removes contaminants and particles that may have accumulated in the oil during engine operation. By maintaining a consistent flow of clean, cool oil, the cooler head contributes to the overall efficiency and cleanliness of the engine’s lubrication system. This not only enhances engine performance but also extends the lifespan of engine components by reducing wear and tear caused by contaminated or overheated oil.

Enhanced Engine Protection

The combination of the Oil Filter Cooler Head with the engine oil cooler and oil filter creates a robust system for maintaining optimal engine oil conditions. This setup ensures that the oil remains at an ideal temperature and is free from contaminants, providing superior protection for the engine. The cooler head’s role in this system is to facilitate the seamless integration and operation of these components, contributing to the engine’s reliability and performance.

Conclusion

The Oil Filter Cooler Head, part 4952497, is a critical component in the maintenance of heavy-duty truck engines. Its role in ensuring the optimal temperature and cleanliness of engine oil contributes significantly to engine performance and longevity. By integrating filtration and cooling functions, this Cummins part enhances engine efficiency, reduces wear on components, and ensures the reliability of the lubrication system. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this component, reflecting Cummins’ commitment to quality and innovation in the automotive industry.

: Wang, Yushu. *Introduction to Engine Valvetrains*. SAE International, 2007.

: Ling, Frederick F. *The Automotive Body*. Springer Science, 2011.

: Heywood, John. *Internal Combustion Engine Fundamentals*. McGraw-Hill Education, 2019.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.