This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Lubricating Oil Filter Head, part number 4929855, is a component designed for use in commercial trucks, specifically within the Cummins engine lineup. Its purpose is to facilitate the filtration of engine oil, ensuring that contaminants are removed to maintain the engine’s efficiency and longevity. This part plays a role in the maintenance and operation of commercial trucks by contributing to the overall health and performance of the engine.

Basic Concepts of Lubricating Oil Filter Heads

A Lubricating Oil Filter Head is an integral part of the engine lubrication system. Its primary function is to house the oil filter and allow for the flow of clean oil throughout the engine. By filtering out impurities and particles from the oil, it helps maintain the lubrication system’s efficiency, which is vital for the engine’s performance and durability 1. The filter head ensures that the oil circulating within the engine remains clean, which in turn supports the engine’s moving parts by reducing wear and tear.

Purpose of the Cummins Lubricating Oil Filter Head

The Cummins Lubricating Oil Filter Head serves a specific role in the operation of a truck. It is responsible for filtering contaminants from the engine oil, which is important for maintaining the oil’s quality and the engine’s performance. Additionally, it helps in maintaining the oil pressure within the engine, ensuring that all moving parts receive adequate lubrication. This component is designed to work in conjunction with the oil filter to provide a barrier against debris and contaminants that could otherwise cause damage to the engine.

Key Features

The Cummins Lubricating Oil Filter Head is characterized by several key features that enhance its performance and durability. Its design is engineered to fit securely within the engine compartment, ensuring a tight seal that prevents oil leaks. The materials used in its construction are chosen for their strength and resistance to the high temperatures and pressures found within an engine. Additionally, this filter head may include unique attributes such as an integrated relief valve or a bypass feature, which allows oil to flow even if the filter becomes clogged, ensuring continuous engine lubrication 2.

Benefits

Utilizing the Cummins Lubricating Oil Filter Head in a truck’s engine offers several benefits. It contributes to improved engine performance by ensuring that the oil remains clean and free of contaminants. This cleanliness leads to reduced friction within the engine, which can extend the engine’s life. Furthermore, by maintaining optimal oil conditions, this component can help reduce maintenance costs associated with engine wear and damage.

Installation Process

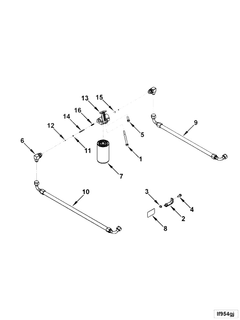

Installing the Cummins Lubricating Oil Filter Head requires careful attention to ensure proper fitting and function. The process involves several steps, including preparing the engine compartment, removing the old filter head if necessary, and securely attaching the new component. Tools required may include wrenches and possibly a torque wrench to ensure that all connections are tightened to the manufacturer’s specifications. It is important to follow the installation instructions provided by Cummins to ensure the filter head is correctly installed.

Troubleshooting Common Issues

Common problems that may arise with the Cummins Lubricating Oil Filter Head include leaks or reduced efficiency in filtering contaminants. Troubleshooting these issues may involve inspecting the filter head for damage, ensuring all connections are tight, and checking the condition of the oil filter. If leaks are detected, it may be necessary to replace gaskets or seals. Reduced efficiency could indicate a clogged filter, necessitating its replacement.

Maintenance Tips

To ensure the optimal performance of the Cummins Lubricating Oil Filter Head, regular maintenance practices are recommended. This includes inspecting the filter head and its connections at regular intervals, as well as replacing the oil filter according to the manufacturer’s guidelines. Keeping the engine compartment clean and free of debris can also contribute to the longevity and efficiency of the filter head.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and quality in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles, ensuring reliability, performance, and efficiency 3.

Cummins Lubricating Oil Filter Head 4929855 Compatibility

The Cummins Lubricating Oil Filter Head, part number 4929855, is designed to ensure the proper flow of oil through the engine’s lubrication system, which is essential for reducing friction and wear on engine components.

Engine Compatibility

The 4929855 oil filter head is compatible with the following Cummins engine models:

- 6B5.9 Series

This part is engineered to fit seamlessly into the specified engine models, ensuring that the oil filtration system operates efficiently. The 4929855 is designed to meet the stringent requirements of these engines, providing reliable performance and durability.

Installation and Usage

When installing the 4929855 oil filter head, it is crucial to follow the manufacturer’s guidelines to ensure proper fitment and function. This includes using the correct torque specifications and ensuring that the oil filter is securely attached to the head. Proper installation is key to maintaining the integrity of the engine’s lubrication system.

Maintenance

Regular maintenance of the 4929855 oil filter head is essential to ensure the longevity and performance of the engine. This includes checking for leaks, ensuring the oil filter is in good condition, and replacing the oil filter head as needed according to the engine’s maintenance schedule.

Role of Part 4929855 Lubricating Oil Filter Head in Engine Systems

The Cummins Lubricating Oil Filter Head is an integral component in the maintenance and efficiency of engine systems, particularly when integrated with full flow oil filters. This component facilitates the seamless connection between the engine’s lubrication system and the oil filter, ensuring that the oil circulates effectively through the engine.

When the engine is operational, the oil pump draws oil from the sump and sends it through the full flow oil filter. The Cummins Lubricating Oil Filter Head acts as the interface that connects the filter to the engine block or the oil filter housing. This connection is vital for maintaining the integrity of the oil filtration process.

As oil passes through the full flow oil filter, contaminants and debris are trapped within the filter media. The clean oil then exits the filter and is directed by the Cummins Lubricating Oil Filter Head to the various engine components that require lubrication. This includes critical areas such as the crankshaft, camshaft, pistons, and bearings.

The design of the Cummins Lubricating Oil Filter Head ensures a secure and leak-free seal, which is essential for maintaining oil pressure within the engine. Consistent oil pressure is necessary for the proper functioning of the lubrication system, as it ensures that all moving parts receive a continuous supply of clean oil.

Conclusion

In summary, the Cummins Lubricating Oil Filter Head, part number 4929855, plays a significant role in the engine’s lubrication system by providing a reliable connection between the full flow oil filter and the engine, thereby contributing to the overall efficiency and longevity of the engine components.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.