This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

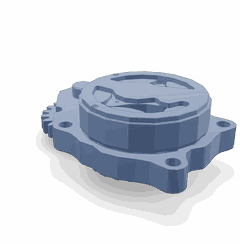

The 4897481 Lubricating Oil Pump by Cummins is engineered to facilitate the circulation of oil within the engine of commercial trucks. This part ensures that engine components receive adequate lubrication, which is essential for the efficient and reliable operation of the vehicle. The pump is integral to maintaining the health and performance of the engine by reducing friction and wear on moving parts.

Basic Concepts of Lubricating Oil Pumps

Lubricating oil pumps operate on the principle of transferring oil from the sump to various engine components. They are typically categorized into gear pumps, gerotor pumps, and vane pumps, each with distinct mechanisms for oil circulation. Proper lubrication is fundamental to the longevity and efficiency of engine components, as it minimizes friction, dissipates heat, and removes contaminants 1.

Purpose of the 4897481 Lubricating Oil Pump

The 4897481 Lubricating Oil Pump plays a role in the operation of a truck by ensuring consistent oil circulation to critical engine components. This includes the crankshaft, camshaft, pistons, and bearings. Adequate lubrication under various operating conditions helps maintain engine performance and protects against wear and damage.

Key Features

The 4897481 Lubricating Oil Pump is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and efficiency. The pump is engineered to withstand the demanding conditions of commercial truck engines, ensuring reliable performance over time.

Benefits

Utilizing the 4897481 Lubricating Oil Pump can lead to improved engine performance, as consistent lubrication reduces friction and wear on engine components. This, in turn, can extend the lifespan of these parts and enhance the overall reliability of the truck’s engine system. Proper lubrication also contributes to more efficient engine operation and can help in maintaining optimal engine temperature 2.

Troubleshooting

Common issues with the 4897481 Lubricating Oil Pump may include inadequate oil pressure, leaks, or pump failure. Symptoms to watch for include unusual engine noises, decreased oil pressure readings, or visible oil leaks around the pump area. Diagnosing these problems may involve checking the oil level and quality, inspecting the pump for physical damage, and ensuring there are no obstructions in the oil passages.

Maintenance

Routine maintenance practices are recommended to ensure the longevity and optimal performance of the 4897481 Lubricating Oil Pump. This includes regular inspections for wear or damage, cleaning the pump and its surroundings to prevent contamination, and following manufacturer guidelines for replacement intervals. Proper maintenance helps in identifying potential issues before they lead to significant problems 3.

Installation

When installing the 4897481 Lubricating Oil Pump, it is important to ensure it is correctly fitted and aligned within the truck’s engine system. This involves following the manufacturer’s instructions for installation, which may include torque specifications for fastening the pump and ensuring all connections are secure and leak-free.

Compatibility with Cummins Engines

The Cummins part number 4897481, which is a lubricating oil pump, is designed to be compatible with several of Cummins’ engine models. This part is integral to ensuring that the engine’s lubrication system operates efficiently, maintaining the necessary oil pressure and flow to various engine components.

ISB CM850 and ISBE4 CM850

The lubricating oil pump part 4897481 fits seamlessly with the ISB CM850 and ISBE4 CM850 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The oil pump ensures that these engines receive the proper lubrication, which is crucial for maintaining engine longevity and performance.

ISB/ISD6.7 CM2150 SN

This part is also compatible with the ISB/ISD6.7 CM2150 SN engines. These engines are part of Cummins’ lineup that emphasizes durability and efficiency, making them suitable for various industrial and commercial applications. The oil pump’s role in these engines is to maintain optimal oil pressure, which is essential for the smooth operation of the engine’s moving parts.

ISBE CM800

The ISBE CM800 engine is another model that benefits from the use of the lubricating oil pump part 4897481. This engine is designed for applications requiring high power output and reliability. The oil pump ensures that the ISBE CM800 engine operates within its designed parameters, preventing wear and tear on critical components.

QSB6.7 CM850 (CM2850)

Lastly, the QSB6.7 CM850 (CM2850) engine is compatible with the lubricating oil pump part 4897481. This engine is known for its versatility and is used in a range of applications, from agricultural to industrial. The oil pump’s function in this engine is to provide consistent lubrication, which is vital for maintaining engine efficiency and performance over time.

Role of Part 4897481 Lubricating Oil Pump in Engine Systems

The lubricating oil pump, identified by part number 4897481, is integral to the efficient operation of various engine systems. Its primary function is to circulate lubricating oil throughout the engine, ensuring that all moving parts are adequately coated to reduce friction and wear.

Interaction with Engine Components

-

Crankshaft and Connecting Rods: The pump delivers oil to the crankshaft and connecting rods, which are subject to high levels of stress and friction. Consistent lubrication here is essential for smooth operation and longevity of these components.

-

Camshaft and Valve Train: The lubricating oil pump ensures that the camshaft and valve train components receive a steady supply of oil. This is particularly important for overhead cam engines where the camshaft is located higher in the engine block.

-

Pistons and Cylinder Walls: Adequate lubrication between the pistons and cylinder walls is vital for minimizing friction and heat generation. The pump plays a key role in maintaining this lubrication.

-

Bearings: Main and rod bearings rely on a consistent flow of oil to prevent metal-to-metal contact, which could lead to premature failure. The pump ensures these bearings are well-lubricated under all operating conditions.

-

Timing Chain or Belt: In engines equipped with a timing chain or belt, lubrication is necessary to reduce wear and ensure precise timing. The pump facilitates this by providing oil to the timing chain or belt components.

-

Oil Filter: The pump works in conjunction with the oil filter to ensure that the oil circulating within the engine is clean and free of contaminants. This partnership is essential for maintaining the integrity of engine components.

-

Oil Cooler: In engines with an oil cooler, the pump helps regulate the temperature of the lubricating oil. By circulating oil through the cooler, it ensures that the oil maintains an optimal temperature for effective lubrication.

-

Turbocharger (if equipped): In turbocharged engines, the lubricating oil pump also supplies oil to the turbocharger bearings. This is essential for the turbocharger’s efficient and reliable operation.

Conclusion

Understanding the role of the 4897481 Lubricating Oil Pump within these engine systems allows engineers and mechanics to better appreciate its significance in maintaining engine health and performance. Proper maintenance and installation of this Cummins part are crucial for ensuring the longevity and efficiency of commercial truck engines.

-

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.