4334001

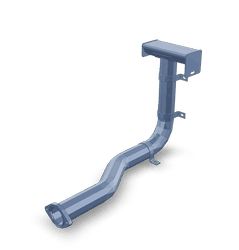

Lubricating Oil Suction Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Lubricating Oil Suction Tube, identified by Part #4334001, is a component manufactured by Cummins. This part is integral to the engine lubrication system, ensuring that oil is efficiently drawn from the oil pan and circulated throughout the engine. Cummins, a reputable manufacturer in the automotive industry, produces this component with a focus on durability and performance 1.

Basic Concepts and Functionality

Lubricating oil suction tubes operate on fundamental principles designed to facilitate the smooth functioning of an engine’s lubrication system. These tubes are responsible for drawing oil from the oil pan and directing it towards the oil pump. This process is vital for maintaining consistent oil pressure and ensuring that all moving parts within the engine receive adequate lubrication. The efficient operation of the suction tube contributes to the overall performance and longevity of the engine by reducing friction and wear on critical components 2.

Purpose and Role in Truck Operation

The 4334001 Lubricating Oil Suction Tube serves a specific function within a truck’s engine lubrication system. Its primary role is to ensure a steady supply of oil is available for the oil pump, which then circulates the oil throughout the engine. This consistent lubrication is crucial for the efficient operation of the truck, as it helps to maintain engine temperature, reduce wear on components, and ensure smooth operation under various driving conditions 3.

Key Features

The 4334001 Lubricating Oil Suction Tube is designed with several features that enhance its performance and durability. These include a robust construction that can withstand the pressures and temperatures within an engine environment. The tube is made from high-quality materials that resist corrosion and wear, ensuring long-term reliability. Additionally, its design may incorporate features that facilitate easy installation and maintenance, contributing to its overall effectiveness in the lubrication system 4.

Benefits

The advantages of using the 4334001 Lubricating Oil Suction Tube include improved lubrication efficiency, which leads to reduced wear on engine components. This enhancement in lubrication can contribute to better overall engine performance and longevity. By ensuring that oil is consistently and efficiently circulated throughout the engine, this component plays a role in maintaining optimal engine operation 5.

Installation and Compatibility

Proper installation of the 4334001 Lubricating Oil Suction Tube is crucial for its effective operation. Installation procedures should follow manufacturer guidelines to ensure that the tube is securely and correctly positioned within the engine. Compatibility with various engine models and makes is an important consideration, as this ensures that the suction tube can be used across a wide range of applications, providing versatility and reliability 6.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the optimal performance of the 4334001 Lubricating Oil Suction Tube. These may include regular inspections for signs of wear or damage, ensuring that connections are secure, and verifying that the tube is free from obstructions. Troubleshooting common issues, such as leaks or reduced oil flow, may involve checking for proper installation, inspecting for damage, and ensuring that the tube is compatible with the engine’s lubrication system 7.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to producing high-quality components. With a rich history and a strong reputation, Cummins has built a legacy of innovation and reliability. The company’s focus on manufacturing excellence is evident in its wide range of automotive components, including the 4334001 Lubricating Oil Suction Tube, which is designed to meet the demanding requirements of modern engines 8.

Lubricating Oil Suction Tube (Part 4334001) Compatibility with Cummins Engines

The Cummins part number 4334001, which is a Lubricating Oil Suction Tube, is designed to fit seamlessly with several Cummins engine models. This part is crucial for ensuring the proper flow of lubricating oil within the engine, thereby maintaining engine health and performance.

QST30 Engines

The Lubricating Oil Suction Tube (4334001) is compatible with the QST30 engine series. This compatibility ensures that the tube fits precisely within the engine’s design, facilitating efficient oil circulation. The QST30 engines, known for their robust performance, benefit from this part’s precision fit, which helps in maintaining optimal engine lubrication.

CM2350 and CM552 Engines

Similarly, the part 4334001 is also designed to fit the CM2350 and CM552 engines. These engines, part of the Cummins lineup, require a reliable oil suction tube to ensure that the lubricating oil is drawn effectively from the sump. The precision engineering of this part guarantees that it integrates smoothly with the engine’s architecture, contributing to the longevity and efficiency of the engine.

Grouping of Engines

The compatibility of the Lubricating Oil Suction Tube (4334001) with the QST30, CM2350, and CM552 engines highlights the versatility and broad applicability of this component. Cummins has ensured that this part meets the stringent requirements of these engines, providing a reliable solution for oil suction needs. This compatibility underscores Cummins’ commitment to providing high-quality, precision-engineered parts that enhance engine performance and reliability.

Role of Part 4334001 Lubricating Oil Suction Tube in Engine Systems

The lubricating oil suction tube, identified by part number 4334001, is integral to the efficient operation of engine systems. This component is responsible for drawing oil from the oil pan and delivering it to the engine’s lubrication system.

During product installation, the suction tube is carefully positioned to ensure a secure fit within the engine assembly. It connects to the oil pan, which serves as the reservoir for the engine’s lubricating oil. The tube’s design allows for consistent oil flow, which is essential for maintaining proper lubrication of moving parts within the engine.

The oil pan, a fundamental component in the lubrication system, collects and stores the engine oil. The suction tube draws oil from this pan and transports it to the oil pump. The oil pump then circulates the oil throughout the engine, ensuring that all critical components receive adequate lubrication.

This process is vital for reducing friction, minimizing wear, and dissipating heat generated by the engine’s operation. The efficient functioning of the lubricating oil suction tube directly impacts the overall performance and longevity of the engine.

Conclusion

The 4334001 Lubricating Oil Suction Tube plays a critical role in the engine lubrication system by ensuring efficient oil circulation. Its robust construction, compatibility with various engine models, and ease of installation contribute to its effectiveness. Regular maintenance and proper installation are essential for maximizing the benefits of this component, ultimately leading to improved engine performance and longevity.

-

Vaclav Smil, The History and Impact of Diesel Engines and Gas Turbines, The MIT Press, 2010.

↩ -

Michael Hilgers and Wilfried Achenbach, Vocational Vehicles and Applications, Springer Vieweg, 2021.

↩ -

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Vaclav Smil, The History and Impact of Diesel Engines and Gas Turbines, The MIT Press, 2010.

↩ -

Michael Hilgers and Wilfried Achenbach, Vocational Vehicles and Applications, Springer Vieweg, 2021.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.