This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4313312 Lubricating Oil Filter Element Assembly is designed to maintain the health and efficiency of heavy-duty truck engines. This assembly is integral to the engine’s lubrication system, ensuring that the oil circulating through the engine remains clean and free of contaminants. Proper maintenance of this component is vital for the sustained performance and longevity of the truck’s engine.

Basic Concepts of Lubricating Oil Filter Element Assemblies

A lubricating oil filter element assembly is a device that filters impurities from the oil circulating within an engine. It consists of a filter medium housed within a metal or plastic casing. As oil passes through the filter medium, contaminants such as dirt, metal particles, and sludge are trapped, preventing them from circulating through the engine and causing wear or damage. Effective oil filtration is fundamental to maintaining engine health, as clean oil ensures proper lubrication of moving parts, reduces friction, and minimizes wear 1.

Role of the 4313312 Lubricating Oil Filter Element Assembly in Truck Operation

The 4313312 assembly plays a specific role in the operation of heavy-duty trucks by ensuring that the engine oil remains clean. This assembly is positioned in the oil circulation path, where it filters out contaminants from the oil before it reaches critical engine components. By maintaining clean oil, the assembly contributes to engine performance and longevity, ensuring that the engine operates efficiently and reliably over time 2.

Key Features of the 4313312 Lubricating Oil Filter Element Assembly

The 4313312 assembly is characterized by its robust design and high-quality materials. It features a durable casing that protects the filter medium, ensuring it can withstand the pressures and temperatures of the engine environment. The filter medium itself is designed to capture a wide range of contaminants, from fine particles to larger debris, enhancing the overall filtration efficiency. Additionally, the assembly is engineered for easy installation and replacement, facilitating maintenance procedures 3.

Benefits of Using the 4313312 Lubricating Oil Filter Element Assembly

Utilizing the 4313312 assembly offers several advantages. It contributes to improved engine efficiency by ensuring that the oil remains clean and effective in lubricating engine components. This can lead to reduced maintenance costs, as clean oil helps prevent wear and damage to engine parts. Furthermore, by maintaining optimal oil cleanliness, the assembly helps extend the engine’s life, providing long-term value and reliability.

Installation Process

Installing the 4313312 assembly requires following a series of steps to ensure proper fitting and function. Begin by ensuring the engine is cool and the oil has been drained to prevent spills. Remove the old filter assembly, taking care to avoid spills and contamination. Inspect the gasket or O-ring for damage and replace if necessary. Lubricate the new gasket or O-ring with a thin layer of clean engine oil before installing the new assembly. Screw the assembly into place by hand until it seats, then tighten it to the manufacturer’s specified torque. Finally, check for leaks after starting the engine and allowing it to run for a few minutes.

Maintenance and Troubleshooting

Regular maintenance of the 4313312 assembly is key to ensuring optimal performance and longevity. This includes replacing the assembly at recommended intervals, typically every oil change, to ensure the filter medium remains effective. When troubleshooting, check for signs of leaks around the assembly, which may indicate a faulty gasket or improper installation. Additionally, monitor the oil pressure and engine performance, as a sudden drop in oil pressure or increased engine noise may signal issues with the filtration system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company offers a wide range of products for various applications, including heavy-duty trucks, where reliability and performance are paramount. Cummins’ commitment to excellence is evident in its product development, ensuring that components like the 4313312 Lubricating Oil Filter Element Assembly meet the highest standards of quality and performance.

Cummins Engine Compatibility with Lubricating Oil Filter Element Assembly Part 4313312

The Cummins Lubricating Oil Filter Element Assembly part number 4313312 is designed to fit seamlessly with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. This part is integral to maintaining the engine’s performance and longevity by ensuring that the oil remains clean and free of contaminants.

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the 4313312 assembly is engineered to provide optimal filtration efficiency. This ensures that the oil circulating through the engine is consistently clean, which is crucial for reducing wear and tear on engine components. The design of the assembly allows for easy installation and removal, facilitating routine maintenance procedures.

The compatibility of the 4313312 assembly with these specific engine models is a result of meticulous engineering and testing. This ensures that the part meets the stringent requirements of the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, providing reliable performance and durability.

Role of Part 4313312 Lubricating Oil Filter Element Assembly in Engine Systems

The 4313312 Lubricating Oil Filter Element Assembly is an integral component within the engine’s lubrication system, working in concert with other elements to ensure optimal engine performance and longevity.

Integration with the Filter

The filter element assembly is the core component of the lubricating oil filter. It is responsible for trapping contaminants and impurities within the lubricating oil, preventing them from circulating through the engine. This ensures that the oil maintains its viscosity and lubricating properties, which are essential for reducing friction between moving parts.

Interaction with Lubricating Oil

As lubricating oil flows through the engine, it picks up debris, metal particles, and other contaminants. The 4313312 assembly plays a significant role in purifying this oil. By filtering out these impurities, it helps maintain the oil’s effectiveness, ensuring that it continues to provide adequate lubrication to critical engine components such as bearings, pistons, and camshafts.

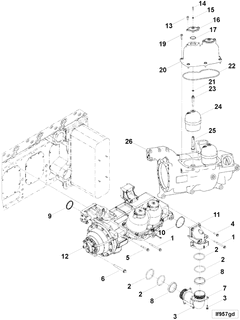

Coordination with Lubricating Oil Filter Head

The lubricating oil filter head houses the filter element assembly and provides the necessary structural support and sealing. The head is designed to direct the flow of oil through the filter element, maximizing the filtration efficiency. The assembly fits snugly within the head, ensuring a secure and leak-free connection. This integration is vital for maintaining the integrity of the filtration process and preventing any bypass of unfiltered oil.

Contribution to Lubricating Oil Filter Kit

In a lubricating oil filter kit, the 4313312 assembly is often included as a replacement part. The kit may also contain the filter head, gaskets, and other necessary components for a complete filter replacement. The assembly ensures that the kit provides a comprehensive solution for maintaining the engine’s lubrication system. When installed as part of the kit, it guarantees that the engine receives clean, contaminant-free oil, which is essential for its efficient operation and durability.

Conclusion

The Cummins 4313312 Lubricating Oil Filter Element Assembly is a critical component for maintaining the health and efficiency of heavy-duty truck engines. By ensuring that the engine oil remains clean and free of contaminants, this part contributes to improved engine performance, reduced maintenance costs, and extended engine life. Proper installation, regular maintenance, and timely replacement of the assembly are essential practices for achieving these benefits.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.