This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Transfer Tube, manufactured by Cummins, is a critical component in the maintenance of heavy-duty trucks. This part facilitates the efficient transfer of lubricating oil to various engine components, ensuring smooth operation and longevity of the vehicle. Cummins, a renowned name in the automotive industry, is known for its commitment to quality and innovation in manufacturing automotive components 1.

Function and Operation

The Lubricating Oil Transfer Tube operates within the truck’s lubrication system by channeling oil from the oil reservoir to different parts of the engine that require lubrication. This includes components such as bearings, pistons, and other moving parts. The tube ensures a consistent flow of oil, which is essential for reducing friction and wear between these components 2.

Key Features

The Lubricating Oil Transfer Tube is designed with several key features that enhance its performance. It is constructed from durable materials that can withstand high temperatures and pressures typical in heavy-duty truck engines. The design includes precise fittings and connections to ensure a secure and leak-free transfer of oil. Additionally, the tube may feature reinforced sections to prevent kinking or damage during operation.

Benefits

The use of the Lubricating Oil Transfer Tube offers several advantages. It contributes to improved lubrication efficiency, which in turn reduces friction between engine components. This leads to smoother operation and can enhance the longevity of the engine parts. Moreover, efficient lubrication helps in maintaining optimal engine performance and can contribute to fuel efficiency 3.

Installation Process

Installing the Lubricating Oil Transfer Tube requires careful attention to detail. The process involves disconnecting the old tube, if present, and connecting the new tube to the oil reservoir and engine components. It is important to use the correct tools and follow safety precautions, such as ensuring the engine is cool and the oil system is depressurized before beginning the installation. Proper alignment and secure fastening of connections are crucial to prevent leaks and ensure efficient oil flow.

Maintenance and Troubleshooting

Regular maintenance of the Lubricating Oil Transfer Tube is important to ensure its optimal performance. This includes checking for leaks, ensuring connections are secure, and inspecting the tube for signs of wear or damage. Common issues may include oil leaks, which can often be traced to loose connections or damaged sections of the tube. Troubleshooting steps involve identifying the source of the leak, repairing or replacing damaged parts, and ensuring all connections are tight and secure.

Compatibility and Applications

The Lubricating Oil Transfer Tube is designed to be compatible with a range of truck models and engine types. Its applications extend to various operating environments, including long-haul trucking, construction, and other heavy-duty operations where reliable lubrication is paramount.

Safety Considerations

When working with the Lubricating Oil Transfer Tube, it is important to follow safety guidelines. This includes proper handling of the tube to avoid damage, secure storage to prevent kinking or crushing, and safe disposal procedures for old or damaged tubes. Always ensure that the engine is cool and the oil system is depressurized before performing any maintenance or installation tasks.

Cummins Overview

Cummins is a leading manufacturer in the automotive industry, known for its wide range of products including engines, filtration systems, and aftermarket parts. The company has a strong reputation for quality and innovation, with a history of developing reliable and efficient components for various applications. Cummins’ commitment to excellence is evident in its product offerings, which are designed to meet the demanding requirements of heavy-duty truck operations.

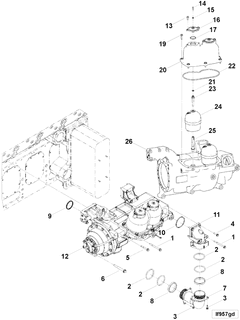

Cummins Engine Compatibility with Lubricating Oil Transfer Tube Part 4313303

The Cummins part number 4313303, which is a Lubricating Oil Transfer Tube, is designed to fit seamlessly within the engine architecture of the QSK95 series. Specifically, this part is compatible with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines.

In these engines, the lubricating oil transfer tube plays a crucial role in ensuring the smooth operation of the engine by facilitating the transfer of oil between different components. This part is engineered to meet the stringent requirements of the QSK95 series, ensuring optimal performance and reliability.

The design of the lubricating oil transfer tube ensures that it integrates perfectly with the engine’s internal mechanisms, providing a reliable pathway for oil flow. This is essential for maintaining the engine’s lubrication system, which in turn helps to reduce wear and tear, and prolong the engine’s lifespan.

By using the Cummins part number 4313303, engine operators can be confident that they are using a component that is specifically designed to work with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, ensuring that the engine continues to operate at peak efficiency.

Role of Part 4313303 Lubricating Oil Transfer Tube in Engine Systems

The 4313303 Lubricating Oil Transfer Tube is an essential component in the efficient operation of various engine systems. It facilitates the seamless transfer of lubricating oil from one part of the system to another, ensuring that all moving components receive adequate lubrication.

Integration with the Lubricating Oil Filter

The transfer tube works in conjunction with the lubricating oil filter to maintain the cleanliness of the oil. As the lubricating oil circulates through the engine, it picks up contaminants and debris. The transfer tube channels the oil to the filter, where these impurities are removed. This ensures that the oil remains clean and effective in reducing friction and wear on engine components.

Connection to the Lubricating Oil Filter Head

The lubricating oil filter head is another component that relies on the transfer tube. This head houses the filter element and plays a key role in the filtration process. The transfer tube delivers the oil to the filter head, allowing for efficient filtration before the oil is redistributed to the engine’s moving parts.

Role in the Lubricating Oil Filter Kit

In a lubricating oil filter kit, which typically includes the filter, filter head, and associated hardware, the transfer tube is a vital link. It ensures that the oil flows correctly through the filtration system and back into the engine. This maintains the integrity of the lubrication system, promoting longer engine life and optimal performance.

Overall Function in the Lubrication System

By ensuring a consistent flow of clean lubricating oil, the 4313303 Lubricating Oil Transfer Tube supports the overall health of the engine. It helps in maintaining the proper viscosity and cleanliness of the oil, which is essential for the efficient operation of pistons, bearings, and other critical engine components.

Conclusion

In summary, the 4313303 Lubricating Oil Transfer Tube is a key component in the lubrication system, working alongside the filter, filter head, and filter kit to ensure that the engine receives clean, well-lubricated oil for smooth and efficient operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.