This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4313122 Oil Seal is designed to prevent oil leakage in commercial trucks, playing a significant role in maintaining the integrity of the engine’s lubrication system. This ensures that oil remains where it is needed for effective lubrication and cooling of engine parts 1.

Basic Concepts of Oil Seals

An oil seal, or rotary shaft seal, is a mechanical device used to prevent leakage of lubricants from rotating equipment. It creates a barrier between the rotating shaft and the stationary housing, allowing the shaft to rotate while keeping the lubricant contained. Oil seals are typically constructed from materials like rubber, leather, or synthetic compounds, and often incorporate a metal reinforcing ring to enhance durability and performance 2.

Purpose of the Cummins 4313122 Oil Seal

This Cummins part is specifically engineered to fit within the engine systems of certain commercial trucks. It maintains the seal at the point where the crankshaft exits the engine block, preventing oil from escaping. This containment ensures that the engine remains properly lubricated, contributing to its efficiency and performance 3.

Key Features

The Cummins 4313122 Oil Seal is characterized by its robust design and the quality of materials used in its construction. It features a durable rubber compound for the sealing lip and a metal reinforcing ring to withstand the pressures and temperatures within the engine environment. These features contribute to its effectiveness in sealing and its longevity in demanding applications.

Benefits

Utilizing this Cummins part offers several advantages, including enhanced engine performance through reliable lubrication, extended component lifespan due to reduced wear from proper lubrication, and increased reliability of the truck’s engine system. These benefits are integral to the efficient operation of commercial trucks, where engine reliability is paramount.

Installation and Maintenance

Proper installation of this part involves ensuring it is correctly positioned and seated to achieve an effective seal. Regular maintenance includes checking for signs of wear or damage and replacing the seal as necessary to prevent oil leaks. Common issues may include oil leakage, which can often be traced back to improper installation or excessive wear.

Performance and Durability

The Cummins 4313122 Oil Seal is designed to perform under the rigorous conditions typical of commercial truck operations. Its durability is a result of the high-quality materials used and its precise engineering, allowing it to maintain an effective seal even under high temperatures and pressures.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and services. With a strong reputation in the commercial truck industry, Cummins is committed to delivering quality and innovative products that meet the demanding needs of its customers.

This Cummins part exemplifies the company’s dedication to quality and performance in automotive components, playing a vital role in the maintenance and efficiency of commercial truck engines.

Compatibility with QSK95 Engines

This oil seal is compatible with several QSK95 engine models, specifically the QSK95 CM2350 K111 and QSK95 CM2350 K113. It is engineered to fit precisely within these engines, providing an effective barrier against oil leaks. Its design ensures that it can withstand the high temperatures and pressures typical of these engine models, maintaining its integrity and performance over time.

Role in Engine Systems

The 4313122 Oil Seal is an essential component in maintaining the integrity and efficiency of various engine systems. It is specifically designed to prevent oil leakage between rotating and stationary parts, ensuring that the engine operates smoothly and efficiently.

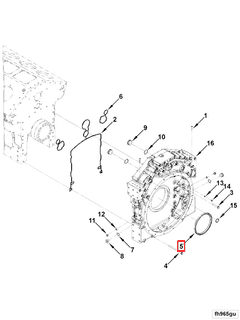

Integration with Flywheel Housing Kit

In the flywheel housing kit, this part is positioned to create a barrier that prevents oil from escaping the housing. This is particularly important as the flywheel housing kit encompasses components that are vital for the transmission of power from the engine to the transmission system. The oil seal ensures that the lubricant remains within the housing, providing consistent lubrication to the moving parts and reducing friction.

Function within the Housing

When installed in the housing, the 4313122 Oil Seal plays a significant role in maintaining the structural integrity of the housing itself. By preventing oil leakage, it helps in maintaining the pressure and lubrication necessary for the proper functioning of the internal components. This is essential for the longevity and performance of the housing, as consistent lubrication reduces wear and tear on the parts.

Interaction with the Flywheel

The flywheel is a key component in the engine system, responsible for storing rotational energy and smoothing out the delivery of power to the transmission. This Cummins part, when installed correctly, ensures that the flywheel remains well-lubricated. This lubrication is vital for the flywheel’s ability to operate efficiently, as it reduces friction between the flywheel and other components, such as the crankshaft and the pressure plate in manual transmissions.

Conclusion

The Cummins 4313122 Oil Seal is a fundamental component in ensuring the smooth operation and longevity of engine systems. Its role in preventing oil leakage and maintaining lubrication is indispensable for the efficient functioning of the flywheel housing kit, housing, and flywheel.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.